Hydraulic Flow Demonstrator - Clear Acrylic Flow Channel 77mm X 150mm X 1100mm | Adjustable Bed Height, Mobile Metal Frame, Diverse Hydraulic Structures

Price: 100 INR / Unit

Get Latest Price

Minimum Order Quantity :

1 Unit

Brand Name :

Teknik

In Stock

Product Specifications

| Product Type | Hydraulic Flow Demonstrator |

| Application | Hydraulic Machinery and Power Tools |

| Usage | Hydraulic Machinery and Power Tools |

| Supply Ability | 100 Per Week |

| Delivery Time | 1 Week |

| Sample Available | Yes |

| Sample Policy | Sample costs shipping and taxes has to be paid by the buyer |

| Packaging Details | carton box, export quality also available |

| Main Export Market(s) | Middle East, Asia, Africa |

| Main Domestic Market | All India |

| Certifications | ISO 9001, 14001 ,CE |

Product Overview

Key Features

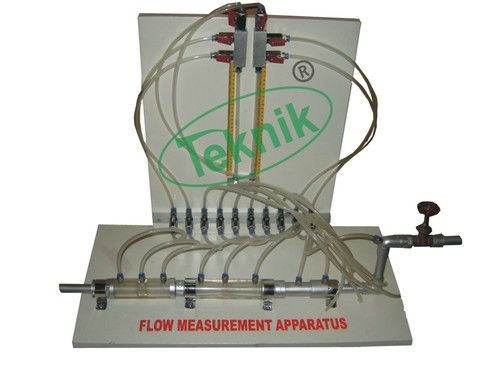

The flow channel of the Hydraulic Flow Demonstrator is constructed using clear acrylic for visibility and is supported by a floor-standing, metal frame fitted with castors for mobility. The flow channel consists of an inlet tank with overflow and flow stilling arrangement, a rectangular working section and a discharge tank. Control valves and adjustable weirs allow the flow conditions to be varied independently at the entry to and exit from the working section. The working section can be flooded to create a closed conduit or operate partially filled as an open channel. The most important feature of this equipment is the adjustable section of the bed which together with its transition section (ramps) may be raised and lowered using an external actuator while the water is still flowing. This facility affords a striking demonstration of the significance of channel critical depth.

DEMONSTRATION CAPABILITIES

Closed Conduit Flow

Application of the Bernoulli and Continuity equations to converging and diverging flow

Effect of gradual and sudden changes in cross section (energy losses)

Using a contraction as a flow-measuring device

Using a Piton tube to measure velocity / velocity profile

Flow through a culvert

Open Channel Flow

Flow beneath an undershot weir (sluice gate)

Flow over sharp-crested, broad-crested and ogee weirs

Using hydraulic structures to measure flow in an open channel

Effect of changes in upstream and downstream water level

Characteristics of clinging, aerated, depressed and drowned napes

Subcritical critical and supercritical flow/ depth.

Changes in specific energy and control imposed by the minimum energy condition

Characteristics of hydraulic jumps

Force and energy conditions in a hydraulic jump

Flow patterns associated with hydraulic jumps

Flow over drop structures / energy dissipation

Changes in flow profile in relation to the Froude Number (predicting flow conditions in an open channel)

Observation of flow patterns associated with flow around hydraulic structures

Velocity of gravity waves in shallow water / Formation of surface waves near critical depth

Project work evaluation of user-constructed hydraulic structures

TECHNICAL SPECIFICATIONS

Maximum operating flow rate: 1.6 l/s

A floor-standing flow channel for use with a hydraulics bench

Working section 77mm wide 150mm high and 1100mm long

Clear acrylic sides for good visibility of flow patterns created

Stilling arrangement at inlet to promote smooth flow into the working section

Section of bed can be elevated continuously and locked at the required height

Discharge tank incorporates flow-control valve for convenience in setting up

Total and static heads indicated on multi-tube manometer connected to Piton tubes and static tapings at three locations in working section

Piton tubes mounted through bed of channel for ease of priming and height adjustment (can be traversed from floor to roof to measure velocity profile)

Transparent scales allow measurement of all important heights and levels

Models of hydraulic structures supplied include undershot weir (sluice gate) at the inlet, overshot weir at the outlet, sharp-crested weir, broad-crested weir (also used to create a culvert) and ogee weir

Suitable for project work with alternative hydraulic structures (user created)

Optional direct reading flow meter to aid setting up of demonstrations

Company Details

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company, Wholesaler, Retailer, Dealer, Fabricator, Producer

Employee Count

25

Establishment

1973

Working Days

Monday To Saturday

GST NO

06ACMPJ7244B1ZS

Certification

ISO 9001 : 2015

Related Products

Explore Related Categories

Seller Details

GST - 06ACMPJ7244B1ZS

Ambala Cantt, Haryana

Ceo

Mr Vikas Jain

Members since

13 Years

Address

Plot No. 73, Vikaspuri, Industrial Area, Ambala Cantt, Haryana, 133001, India

hydraulic flow meter in Ambala Cantt

Report incorrect details