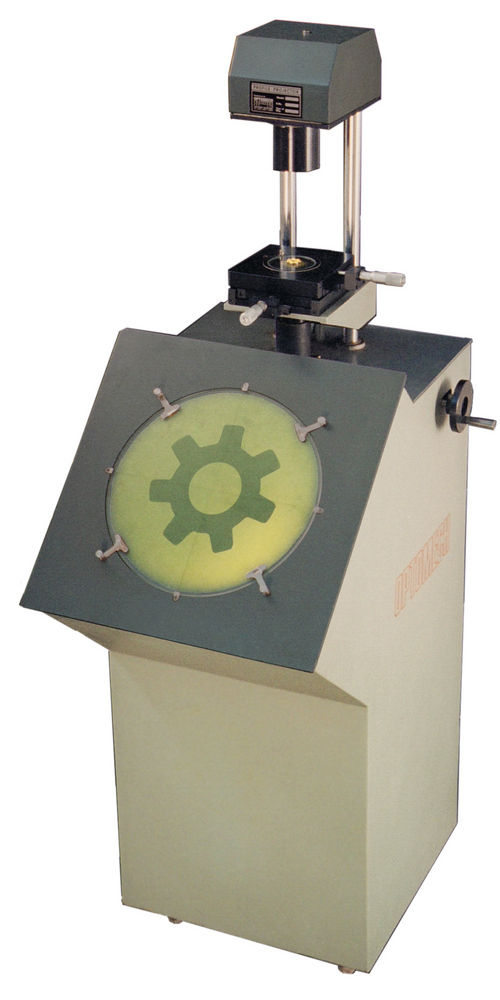

Industrial Bottle Inspection System - 2100 X 1000 X 1440 Mm , High Speed Machine Vision Cameras, User-defined Tolerances, 3 Level Access Control, Database Storage

Price: 2600000.00 INR

(2600000.00 INR + 0% GST)

Get Latest Price

Minimum Pack Size :

1

In Stock

Product Specifications

| Color | Black |

| Computerized | Yes |

| Control Mode | Automatic |

| Voltage | 415 V AC Watt (w) |

| Power | AC 415 V , 3 phase 5A Ampere (amp) |

| Weight (kg) | 150 Kilograms (kg) |

| Dimension (L*W*H) | 2100 x 1000 x 1440 Millimeter (mm) |

| FOB Port | Ex works |

| Delivery Time | Within 10 to 12 weeks of the receipt of your formal order with advance Week |

| Packaging Details | Wooden packing |

| Main Domestic Market | All India |

| Unit Type | Piece/Pieces |

| Product Unit | 1 Piece/Pieces |

| Price Type | fixed |

| Price | 2600000.00 INR (Approx.) |

| Moq | 1 |

| Mop | 1 |

| Stock Quantity | 5 |

| Returnable | No |

| Currency | INR |

| Color | Black |

| Brand Name | Optomech |

| Minimum Order Quantity | 1 |

| Minimum Ordered Packs | 1 |

| GSTIN | 0% |

Product Overview

Key Features

.Each bottle is inspected for defects like spots, material inclusions, colour smears, colour shade variations, flashes, ovality and diameter variations, holes and transparency.

High speed, machine vision cameras, precision optics and customised lighting coupled with state of the art 21 CFR Part 11 compliant software provide security, accuracy and repeatability.

.3 Level access control for a Usera , a Supervisora and a Administratora through separate passwords.Easy to define tolerances allow the user to decide which bottles need to be accepted and which need to be rejected.

.All the product data is stored in a database and can be retrieved at any time.

.The system changes over quickly to inspect new products. Changeover involves simply .Selecting the required product from the system library using the touchscreen.

.The large monitor displays the image of the bottles as they are passing through the system. .Periodic reports are generated as per user-defined frequency eg. hourly, daily, weekly etc.

.Each bottle is inspected for the following defects

Outer Sidewall:

. Black Spots, Material inclusions, Burn Spots.

. Color smears and color shade variations.

. Holes.

. Thin walls.

. Incomplete blowing/ Bottle shape variation.

. Top Sealing Surface:

. Flashes, Extra material

. Under/Short moulding, Nicks, Dents

. Ovality and Diameter variations

. Seal surface integrity

. Choked Neck/ Blockage

Outer Base:

. Black Spots, Material inclusions, Burn Spots

. Holes

. Thin walls

Inside the Bottle:

. Dark spots

. Material insert/Extra material

. Contamination

Neck/Thread area:

. Thread damage

. Ratchet Damage

. Black spots, Material inclusions, Burn spots

. Holes and thin walls

. Incomplete blowing /Bottle shape variation

Company Details

Focusing on a customer-centric approach, Optomech Engineers Pvt. Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Pharmaceutical Machinery in bulk from Optomech Engineers Pvt. Ltd. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

30

Establishment

1986

GST NO

36AAACO2406P1ZC

Related Products

Explore Related Categories

Seller Details

GST - 36AAACO2406P1ZC

Hyderabad, Telangana

Director

Mr. Amit Garg

Address

3-A, Type II, Prasahanthi Nagar, I.E., Kukatpally, Hyderabad, Telangana, 500072, India

bottle inspection machine in Hyderabad

Report incorrect details