Draught Fan

(2364 products)High Gloss Abs Body Ventilation Fan Blade Material: Plastic

Product TypeDraught Fan

Power ModeElectric

Installation TypeWall Mount

Blade MaterialPlastic

WarrantyYes

Induced Draft Fans - Color: White

Price: 24000 INR/Piece

MOQ1 , Piece/Pieces

UsageIndustrial

Power1.5 Watt (w)

Speed1350 RPM

Voltage230 Volt (v)

ColorWhite

Power ModeElectric

R. K. Engg. Works Pvt Ltd.

Mumbai

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller12 Years

Large Fan For Industry And Commercial Spaces

MOQ1 Piece/Pieces

Payment TermsOthers, Cash Against Delivery (CAD)

Delivery Time15 Days

Main Domestic MarketAll India

Golden Engineering Co. Pvt. Ltd.

Vadodara

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller20 Years

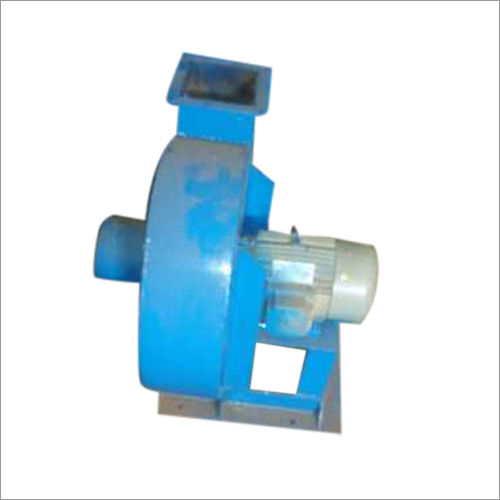

Forced Draft Fans - Capacity: Customer To Specify M3/Hr

Price Trend: 50000.00 - 300000.00 INR/Number

MOQ1 Number

Flow RateCustomer to specify

Motor PowerAs per application Kilowatt (kW)

Output PowerAs per application Horsepower (HP)

Vaccum Range50 to 1500 mmwc Pa

Max PressureCustomer to specify m3/hr

Pressurizationhigh Pressure

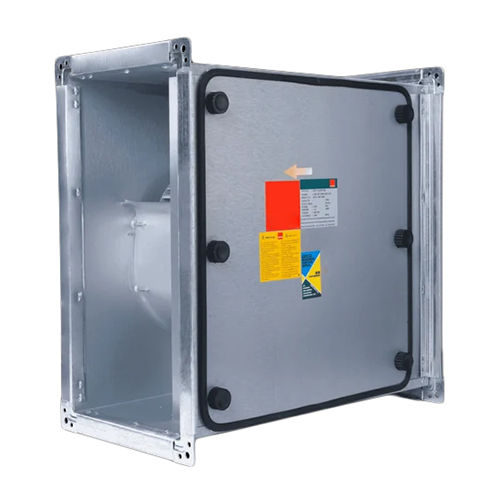

Negative Ventilation Exhaust Box Fan

Product DescriptionNegative Ventilation Exhaust Box Fan

Portable Man Cooler - Blade Material: Aluminum Alloy

Price: 26000 INR/Piece

MOQ1 , Piece/Pieces

ColorYellow And Silver

UsageIndustrial

Blade MaterialAluminum Alloy

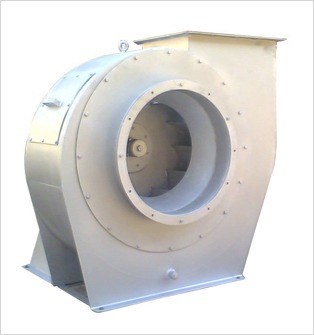

Centrifugal Fan System - Color: White

Price: 95000 INR/Piece

MOQ1 Piece/Pieces

UsageIndustrial

SizeStandard

ColorWhite

Product TypeDraught Fan

Power ModeElectric

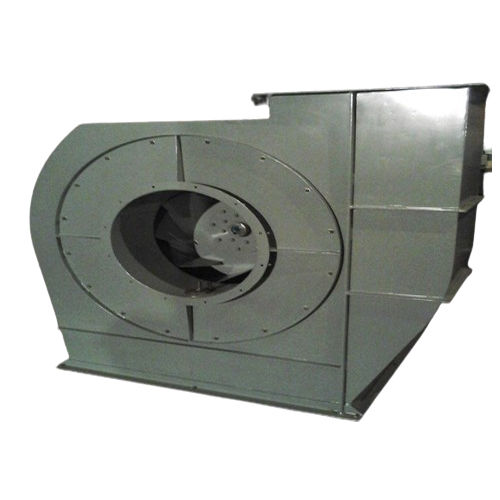

Centrifugal Fan - Mild Steel, 100M³/hr to 25000M³/hr , Low Power Consumption, Excellent Performance, Less Maintenance, Optimum Durability

Product DescriptionSince 1993, we are instrumental in manufacturing, exporting and supplying a broad spectrum of Centrifugal Fan in Pune, Maharashtra, India. Offered fan is manufactured using quality tested components and innovative techniques under the vigilance of our skilled engineers. This fan is installed in food

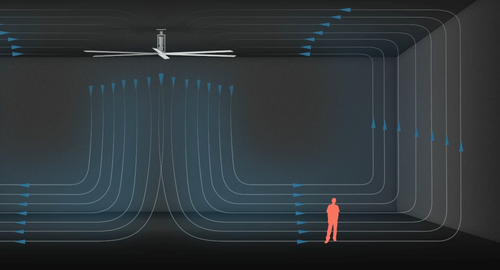

HVLS Fans

Price Trend: 150000.00 - 300000.00 INR/Unit

MOQ1 Unit/Units

Product DescriptionHVLS Fans

Fanair India Private Limited

Alwar

Premium Seller

Premium SellerIndustrial Centrifugal Fan Blade Material: Stainless Steel

MOQ1 Unit/Units

UsageIndustrial

Power ModeElectric

Installation TypeFree Standing

Blade MaterialStainless Steel

WarrantyYes

Rajdeep Engineering Systems Pune Private Limited

Pune

Super Seller

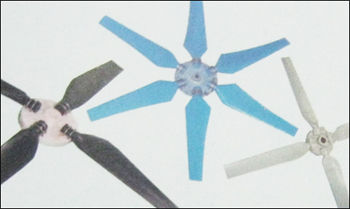

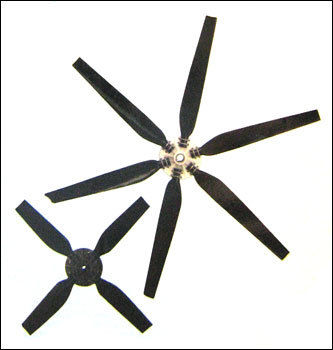

Super SellerEnergy Efficient Fan

Product DescriptionWe are one of the finest company in the industry, involved in Manufacturing, Supplying and Exporting best quality Energy Efficient Fan. These are aerodynamically designed to give maximum fan efficiency and a long life when handling saturated air at high velocity. Moreover, these are completely vibra

Avani Artech Cooling Towers Private Limited

Hyderabad

Trusted Seller

Trusted Seller2 Years

Premium Seller

Premium SellerFrp Fans

Product DescriptionDriven by perfection, we are engaged in manufacturing and supplying a quality range of FRP Fans. Widely used in air cooled heat exchangers and cooling towers, these FRP fans are manufactured in accordance with industry laid guidelines. Along with this, our experts strictly monitor every stage of pro

Wad IL 31 - 12 Inch Inline Exhaust Fan

Price: 37990.00 INR/Unit

MOQ1 Unit/Units

Supply Ability100 Per Week

Delivery Time1 Week

Wadbros Imports & Exports

Mumbai

Trusted Seller

Trusted Seller8 Years

Premium Seller

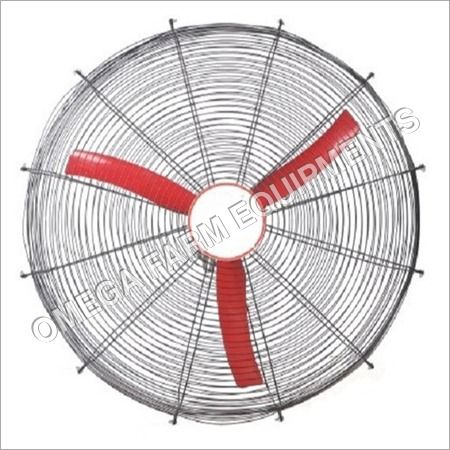

Premium SellerGreenhouse Exhaust Fan - Blade Material: Stainless Steel

Price: 18500.0 INR/Unit

MOQ1 Unit/Units

Size40,50 Inch

ColorSilver

Power1,1.1 Watt (w)

Power ModeElectric

Installation TypeFree Standing

Blade MaterialStainless Steel

Precool Tech Industries Private Limited

Ahmedabad

Trusted Seller

Trusted Seller1 Years

Premium Seller

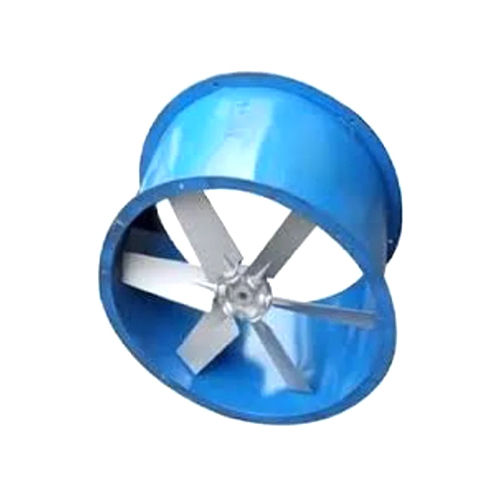

Premium SellerTube Axial Fan - Electric Power Mode | High Efficiency, Durable Design, Energy-Saving Performance

Price: 75000 INR/Piece

MOQ10 Piece/Pieces

Power ModeElectric

Laxmi Udyog

Mumbai

Trusted Seller

Trusted Seller14 Years

Super Seller

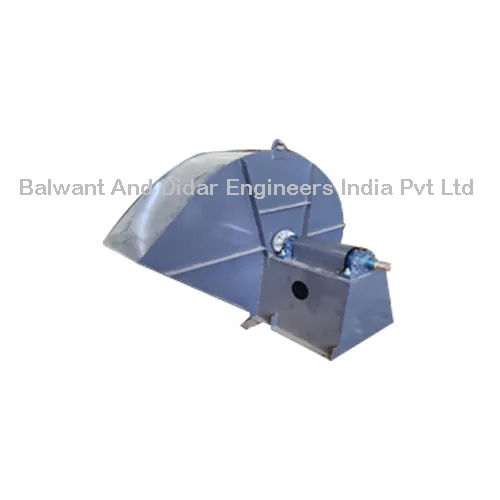

Super SellerMild Steel Industrial Id Fan - Installation Type: Free Standing

Price: 20000 INR/Unit

MOQ1 Unit/Units

Voltage200-250 Volt (v)

Product TypeDraught Fan

Power ModeElectric

Installation TypeFree Standing

Blade MaterialStainless Steel

Warranty1 Years

Balwant And Didar Engineers India Private Limited

Kolkata

Trusted Seller

Trusted Seller2 Years

Premium Seller

Premium SellerWhite Heavy Duty Poultry Exhaust Fan

UsagePoultry

Product TypeDraught Fan

Type of FanExhaust

Awon Plastics

Dhuri

Trusted Seller

Trusted Seller7 Years

Premium Seller

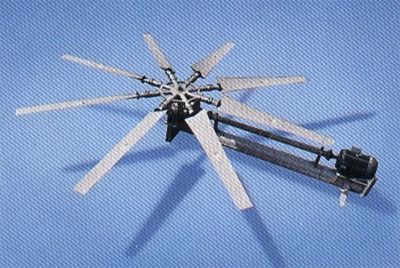

Premium SellerFixed and Variable Vane Axial Fan

Product DescriptionWe have gained a reputed position in our domain by manufacturing, exporting, trading, distributing and supplying a varied variety of Fixed and Variable Vane Axial Fan in Ahmedabad, Gujarat, India. With assistance of our diligent professionals, we manufactured the offered products with superior raw

Heavy Duty Wall Mounting Exhaust Fan Blade Material: Stainless Steel

Price: 23000.0 INR/Nos

MOQ1 Nos

Blade MaterialStainless Steel

Warranty1 year

Quality Systems And Equipments Private Limited

Mumbai

Trusted Seller

Trusted Seller13 Years

Premium Seller

Premium SellerEol Ventilation Fans With Blower Duct Blade Material: Stainless Steel

MOQ10 Unit/Units

UsageIndustrial

Power ModeElectric

Installation TypeFree Standing

Blade MaterialStainless Steel

Ventilation Engg Co.p.ltd.

Kolkata

Trusted Seller

Trusted Seller3 Years

Premium Seller

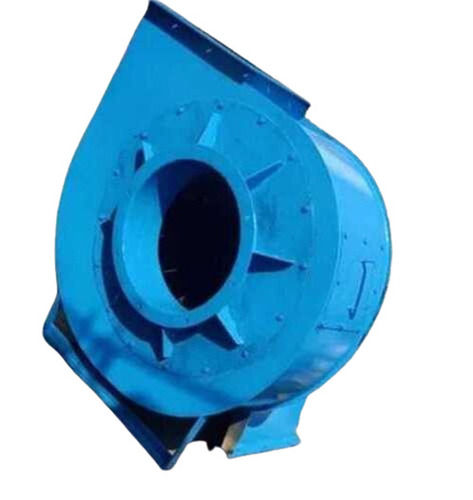

Premium SellerBlue Couple Drive Fan

Price: 145000.00 INR/Piece

MOQ1 Piece/Pieces, Piece/Pieces, Piece/Pieces

Noise Level85 db

Flow Rate500 CFM TO UP

Product TypeINDUSTRIAL

Power415 V Watt (w)

Pressurizationhigh Pressure

Voltage415 Volt (v)

Jaldhara Industries

Ahmedabad

Trusted Seller

Trusted Seller13 Years

Super Seller

Super SellerStainless Steel Misting Fans - Color: Silver

Price: 11800 INR/Piece

MOQ1 Piece/Pieces

Product TypeMisting Fans

UsageIndustrial and Commercial

ColorSilver

Voltage220-240 Volt (v)

SizeStandard

Power ModeElectric

Bhutani International Pvt. Ltd.

New Delhi

Trusted Seller

Trusted Seller17 Years

Super Seller

Super SellerGrey Industrial Centrifugal Fan

MOQ1 Unit/Units

ColorGrey

Product TypeIndustrial Centrifugal Fan

Voltage220-440 Volt (v)

SizeDifferent Size

Type of FanIndustrial Centrifugal Fan

Power ModeElectric

Filtotech Air Control System Private Limited

Kolkata

Trusted Seller

Trusted Seller14 Years

Premium Seller

Premium SellerAnti Corrosive Fan

Product DescriptionOur anti corrosive fan are made from high quality corrosion proof material which ensures durability

Shri Avirat Frp Moulders

Ahmedabad

Trusted Seller

Trusted Seller7 Years

Super Seller

Super SellerRoof Top Ventilation Fan - Color: Silver And Red

Price: 8500.0 INR/Piece

MOQ1 Piece/Pieces

UsageCommercial

ColorSILVER AND RED

Product TypeRoof Top Silver and Red Ventilation Fan

Power ModeElectric

Blade MaterialOther

Omega Farm Equipments

Mumbai

Trusted Seller

Trusted Seller12 Years

Premium Seller

Premium SellerPropeller Fan - Color: Grey

MOQ1 Unit/Units

UsageIndustrial

Voltage220-240 Volt (v)

ColorGrey

Power ModeElectric

WarrantyYes

Techno Products Development Pvt. Ltd.

Chennai

Trusted Seller

Trusted Seller2 Years

Premium Seller

Premium SellerChimney Fans

Product DescriptionKnowing us as a reputed firm, we are engaged in manufacturing, supplying as well as trading a wide range of Chimney Fans in Chhatral, Gujarat, India. This range of fans are manufactured by making use of best quality raw materials, procured from well-known vendors of the industry. One can avail this

Uma Techno Fab

Mehsana

Trusted Seller

Trusted Seller2 Years

Premium Seller

Premium SellerAxial Fans

Product DescriptionOur provided Axial Fans are fabricated under the guidance of our skilled professionals. Our fans are defect free quality and striking in various other factors. These Axial Fans are made by using superior quality materials and innovative technology. Moreover, we provide this fans at very feasible cos

National Engineers (india)

Chennai

Trusted Seller

Trusted Seller6 Years

Premium Seller

Premium SellerLatest From Draught Fan

10 Hp Mild Steel Induced Draught Fan For Industrial

By:

Vikas Air Fans

Induced Draught Fan

By:

Chandan Engineering Works

DRAUGHT FAN

By:

Multivent Engineers

Axial Flow Draught Fan

By:

Filtotech Air Control System Private Limited

Ready To Ship Draught Fan

Introduction to Draught Fan

The draught fan is the conductor in the ventilation world, coordinating the symphony of air flow and guaranteeing a comfortable environment. A draught fan, often referred to as an exhaust fan or a ventilation fan, is essential in many industrial and commercial environments because it promotes air flow and preserves a comfortable climate. A draught fan's main job is to remove or supply air from or to a specific area, maintaining appropriate air circulation and ventilation. These fans are frequently used in manufacturing facilities, power plants, HVAC systems, restaurants, and other locations where maintaining indoor air quality and temperature is crucial. Draught fans assist in preserving a healthy and comfortable working atmosphere while also minimizing the formation of harmful gases by eliminating stale air, odors, and contaminants. They may be tailored to fit specific demands because they are available in a range of sizes, styles, and power levels. In general, draught fans are essential for encouraging airflow, managing temperature, and improving the general quality of indoor air in a variety of environments.

Overview of Draught Fan And Its Types

A draught fan, colloquially referred to as an exhaust fan or a ventilation fan, assumes an indispensable role in diverse industrial, commercial, and residential domains. Its cardinal objective entails efficaciously facilitating the passage of air by engendering extraction or supply mechanisms tailored to specific spaces.

Draught fans come in a wide variety of forms, each suited to certain uses and specifications. They are well known for playing a crucial role in ventilation systems. The centrifugal fan is a well-known variation, distinguished by its curved impeller blades that drive air in a radial direction. This kind is perfect for applications requiring strong airflow resistance since it has improved pressure capabilities. The axial fan, which is characterized by its propeller-like construction and linearly drives air down the axis of rotation, is another notable variety. Axial fans, renowned for their effective airflow delivery, are useful in settings requiring just modest pressure differentials.

Additionally, mixed-flow fans balance pressure and airflow by combining the advantages of axial and centrifugal fans. These fans show flexibility in adapting to various duct conditions. Vane axial fans thrive in some situations because they have changeable blade angles that provide fine control over airflow direction. Plenum fans are also ideally suited for locations with little installation space because of their cylindrical form and compact construction.

Importance of Draught Fan

Draught fans are pivotal in assuring optimal ventilation, seamless air circulation, and impeccable air quality within an array of settings. Predominantly utilized in factories, power plants, HVAC systems, kitchens, and other pertinent locales where temperature regulation and pollutant elimination are requisite, these fans exhibit an ardent commitment to curating a congenial and salubrious interior milieu. By extracting stagnant air, noxious fumes, and olfactory nuisances, draught fans proactively engender an atmosphere of comfort and well-being. Moreover, their malleability enables tailoring to distinct requirements through a gamut of size variants, design configurations, and power capacities. Overall, the quintessential role of draught fans resides in the assiduous promotion of unimpeded airflow, thus efficaciously mitigating the risk of potential airborne contaminants and ensuring optimal ambient conditions.

Draught Wan Working Principle

A draught fan operates on the principles of fluid dynamics and mechanical engineering, which are representative of its inventiveness and functional brilliance. The fan's motor, which frequently has complex electromagnetic or induction systems, transmits rotational energy to the fan blades when it is turned on. These expertly crafted blades use the energy provided by the engine to start the airflow. Ambient air is drawn in and forced to follow the fan's spin as it moves. Centrifugal force is applied to the air by curved impeller blades in centrifugal fans, which causes the air to be ejected perpendicular to the axis of rotation and creates a pressure differential.

Effective ventilation is supported by this pressure difference, which introduces new air into the system or expels stale air. As opposed to this, axial fans use the axial flow pattern to drive air linearly along the axis of rotation, which helps to effectively disperse airflow. Draught fans masterfully transform mechanical energy into fluid motion, harnessing the principles of fluid dynamics to create impeccable air circulation and ventilation in a variety of industrial, commercial, and residential settings. They do this by adhering to meticulous design principles, optimizing blade angles, and streamlining air passages.

Draught Fans - Industrial Applications

Draught fans, revered for their crucial function in industrial areas, have had a significant impact across a variety of industries, demonstrating their adaptability and necessity. These robust and effective ventilation systems have ushered in a paradigm shift, revolutionizing industrial processes and providing excellent working conditions in anything from large manufacturing facilities to expansive commercial buildings. Draught fans play a crucial role in the manufacturing sector by deftly controlling temperature, humidity, and air quality, protecting the toughness of manufactured goods, and securing the sanctity of industrial environments. Exemplifying their abilities, these fans help machinery dissipate heat wisely, reducing the risks of overheating and creating a comfortable climate favorable to improved equipment performance. These premium quality fans also skillfully remove harmful vapors, poisonous gases, and particle matter, ensuring that a workplace is a safe place for diligent workers and adhering strictly to strict safety regulations.

Growth of the Draught Fans Market

The market for draught fans has experienced exponential expansion, which is evidence of the rising need for effective ventilation solutions in a variety of sectors. This paradigm shift can be attributed to widespread environmental sustainability awareness, strict laws, and a growing interest in energy savings. These reasons have prompted the use of highly developed draught fans, which not only guarantee great air circulation but also demonstrate improved energy efficiency and decreased noise levels. Additionally, the market has evolved thanks to the development of smart technologies like IoT integration and enhanced control systems, which provide smooth monitoring, automatic optimization, and predictive maintenance capabilities. The draught fan market has experienced transformational development, underscoring its critical role in promoting healthier indoor environments, streamlining industrial processes, and accelerating economic growth.

FAQs: Draught Fan

Q. What is the draught process?

Ans. The method by which air flow is produced or aided in a particular direction inside a ventilation or combustion system is referred to as the draught process, sometimes known as the draught process. It entails the regulated movement of air, either naturally occurring or via the use of mechanical apparatuses such as draught fans or blowers, to produce a particular airflow pattern. In order to provide optimum ventilation, effective combustion, and the removal of waste gases or undesirable byproducts from industrial operations, the draught process is the main goal. The draught process in the context of ventilation systems involves establishing a pressure difference between two or more compartments, which is commonly accomplished by either exhaust fans or supply fans. By causing air to travel from high-pressure to low-pressure regions, this pressure difference effectively circulates fresh air, eliminates stale air, and maintains a climate that is favorable for inhabitants or industrial activities.

Q. What is Draught fan in a thermal power plant?

Ans. A thermal power plant needs a draught fan, sometimes referred to as an induced draught (ID) fan or a forced draught (FD) fan. Its major job is to establish and maintain an air or gas flow through the boiler and chimney system.

A boiler in a thermal power plant burns fuel, such as coal or natural gas, to create high-pressure steam. After that, a turbine is spun by the steam to produce energy. Flue gases, which also contain hot air and other byproducts, are released by the burning fuel during the combustion process.

Q. What is a Forced-Draft Fan?

Ans. Forced draught fans are referred to as devices that pressurize an area or produce mechanical air pressure in a system. On occasion, standards call for a certain positive pressure to be maintained in production areas. Processes used in clean rooms for scientific activity frequently have this necessity. Air is pushed into the boiler through a preheater by an FD fan, also known as a forced draught fan, which takes air from the environment. These fans are positioned near the boiler's entrance to force fresh air at high pressure into the combustion chamber, where it combines with the fuel to create positive pressure.

Q. What is the cost of a draught fan in India?

Ans. A draught fan's price in India might change based on several variables, including its power rating, size, quality, brand, and source. The price also depends on the market, region, and particular requirements. Without detailed information, it is challenging to estimate the cost precisely. Rough estimates place the cost between 4000.00 and 120000.00 INR. It is advised to get in touch with draught fan manufacturers, suppliers, or authorized distributors in India to obtain precise price information. Based on your unique requirements and specifications, they may offer you comprehensive estimations.

Manufacturers & Suppliers of Draught Fan

Company Name | Member Since |

|---|---|

Fanair India Private Limited Alwar, India | 21 Years |

Golden Engineering Co. Pvt. Ltd. Vadodara, India | 20 Years |

United Air Tech Industries Mumbai, India | 17 Years |

Ascent Machineries & Engg. Services Mumbai, India | 17 Years |

Bhutani International Pvt. Ltd. New Delhi, India | 17 Years |

P-Square Technologies Pune, India | 16 Years |

Laxmi Udyog Mumbai, India | 14 Years |

Filtotech Air Control System Private Limited Kolkata, India | 14 Years |

Kpt Industries Limited Pune, India | 13 Years |

Quality Systems And Equipments Private Limited Mumbai, India | 13 Years |

Popular Products