Industrial Molasses Pump

| Delivery Time | 1 Week |

| Sample Policy | Contact us for information regarding our sample policy |

| Main Export Market(s) | Middle East, Asia |

| Main Domestic Market | All India |

Product Overview

Key Features

Company Details

Syno Pumps, PC Pump Experts

Our business, Syno Pumps, entrenched its roots from its parent company, Syno Pumps & Allied Rubber Industries, which commenced in the year 1968 as a manufacturer of rubber products for the automotive industrial sector. In 1970, when single screw pump technology was introduced in the Indian market, Syno was already manufacturing rubber stators. However, seeing the increasing demands of pumps in the market, we ventured into the domain of pump manufacturing under the name Syno Pumps. We quickly gained fame through our dedication to quality. Thanks to enthusiastic market reaction, the pump production also increased.

Progressive Cavity Pumps still were imported by many Indian players because of the monopolistic circumstances of the nation. Realizing the need for quality pumps built in the Indian soil, we upgraded our production facility and got backed up with advanced resources to work as a manufacturer of Progressive Cavity Pump along with other pump varieties including Roto Pump, Netzsch Pump and Screw Pump. Leveraging the popularity and success of our company, Spares India was founded in the year 1993 as a sister-in-concern to manufacture spare parts for domestic and irrigation requirements.

Late Shri Ishwar Singh laid the foundation of our parent company Syno-PCP Pumps Private Limited & Allied Rubber Industries in the year 1968. By 70s, this company began manufacturing stators and elastomer components, gaining excellent technical know-how in the process. Later, in 1975, Syno Pumps was introduced by Shri Avtaar Singh. Leading the Syno Group as the Managing Director, he has taken the group to global level.

Realizing that every application has its unique functioning characteristics and utility requirements, we manufacture Progressive Cavity Pumps in many specifications today. Besides, our parent company covers almost 280 sugar mills across different Indian locations.

Application Areas

Application areas of our Progressive Cavity Pumps and other pumps include the following:

- Waste Water

- Pharmaceutical

- Chemical

- Pulp & Paper

- Food

- Sugar & Distillery

- Power and Oil

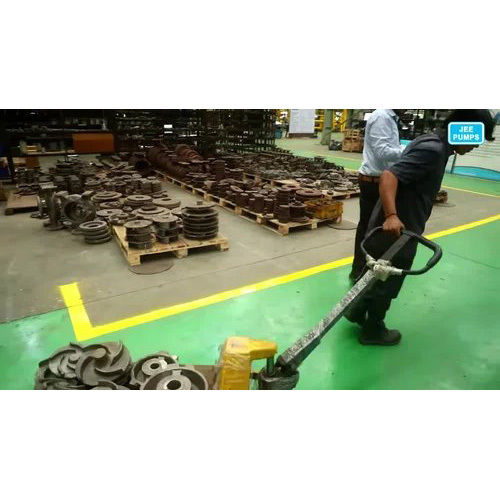

Our Core Asset: Manufacturing & Infrastructure

Our production factory has all the tools required for designing and manufacturing a wide variety of pumps. With our CNC, special purpose machines and other machines including rotor machining equipment, rotary drilling equipment, horizontal boring equipment, long thread milling equipment, milling centers, vertical boring equipment, etc., we fabricate Progressive Cavity Pump and other varieties of pumps of nonpareil quality. Additionally, we have an internal polymer plant for the production of stators. We have also built a modern, robust pattern shop and tool room for manufacturing the complex engineered steel cores for the stators, fixtures and jigs for enhanced productivity levels.

With an in-house manufacturing facility including formulation compounds, rubber mixing and an advanced laboratory unit, we not only manufacture PCP of unflagging quality, but come up with innovative Roto Pump, Screw Pump and Netzsch Pump.

Why Choose Syno Pumps?

- We have an experience of 47 years in this competitive business line of pump making.

- We have the capability of custom manufacturing Screw Pump, Roto Pump, etc.

- We are backed by robust R&D to ensure product innovation and high quality standards.

- We provide round the clock customer support service.

Quality

To uphold our promise of quality products as per our quality policy, we strive day and night to consistently deliver a well-engineered range of Screw Pump, Netzsch Pump and more, thereby surpassing the expectations of our clients in terms of quality. To never miss an opportunity of ongoing improvement, we implement our quality norms across every level of work. Besides, we regularly review set objectives and regulations as per our ISO 9001:2000 certification.

Vision

We can be seen working towards our objective of engineering premium pumps and spare components through the following:

- Creating a work environment facilitating product innovation and professional growth.

- Offering innovative and sturdy products to our valuable clients.

- Expanding our global network and product range.

Our Future Plan

Our medium-term business strategy calls for the inclusion of quality products like Roto Pump, Progressive Cavity Pump, etc. Besides, it requires emphasis on the growth of Mid-Eastern countries. Moreover, we would in future like to expand our polymer plant and involve the production of rubber parts for several customers and industrial sectors.

Global Presence

Our business strategy has always been to make our presence worldwide. For this reason, we have set up a large logistics network. Supported by this network, we have done 5000 installations of Progressive Cavity Pumps, Screw Pump and pumps of various specifications in MEA, North America, Europe, Latin America and Asia.

Customer-First Approach

We follow a collaborative approach while working with our esteemed customers. This ensures that we understand each other completely while guaranteeing that our solutions match the requirements of our customers.

Clientele

Our clients are our most treasured assets with whom we have nurtured long term relationships by focusing on commitment, integrity and passion.

|

|

Fact Sheet of Syno Pumps

|

Nature of Business |

Exporter, Manufacturer and Supplier |

|

Business Location |

Kanpur, Uttar Pradesh |

|

GM-Marketing & Exports |

Mr. Malkeet Singh |

|

Year of Establishment |

1975 |

|

No. of Employees |

N/A |

|

Export Percentage |

15 |

|

Monthly Production Capacity |

N/A |

|

Quality Certification |

ISO 9001:2000 |

|

Warehousing Facility |

N/A |

|

GST No. |

09ABKPK7267N1ZT |

Business Type

Exporter, Manufacturer, Supplier, Producer

Establishment

2000

Working Days

Monday To Sunday

GST NO

09ABKPK7267N1ZT

Certification

ISO 9001 : 2000

Seller Details

SYNO PUMPS

GST

09ABKPK7267N1ZT

Managing Director

Mr. Malkeet Singh

Member Since

16 Years

Address

K-11, Site no. 3, Panki Industrial Area, Kanpur, Uttar Pradesh, 208022, India

molasses transfer pump in KanpurReport incorrect details

Related Products

Sturdy Construction Molasses Transfer Pump

Price - 60000 INR (Approx.)

MOQ - 1 Unit/Units

SAKSHAM INDUSTRIES

Kanpur, Uttar Pradesh

Stainless Steel 20Hp Molasses Transfer Pump

Price - 42000 INR (Approx.)

MOQ - 1 Unit/Units

SAKSHAM INDUSTRIES

Kanpur, Uttar Pradesh

Golden Molasses Transfer Pump

Price - 8000 INR (Approx.)

MOQ - 1 Piece/Pieces

JEE PUMPS LIMITED

Ahmedabad, Gujarat

Molasses Transfer Pump - Color: Blue

Price - 20000 INR (Approx.)

MOQ - 1 Number

AJAY ENGINEERING

Vadodara, Gujarat

Molasses Transfer Pump

Price - 24500 INR (Approx.)

MOQ - 1 Piece/Pieces

Radial Pumps Industries

Ahmedabad, Gujarat

More Products From This Seller

Explore Related Categories

Recommended Products

Popular Products

Human HairForklift TrucksServo Voltage StabilizerBasmati RiceBackhoe LoaderCarry Bag Making MachineDrum LifterElectric StackerScissor LiftsIndustrial Vibrating ScreenRotameterFlowmeterRotary Air CompressorIndustrial Eto SterilizerRice Packaging MachinesShredding MachineHammer MillAutomatic Labelling MachineDiesel ForkliftAerial Work PlatformStorage Rack SystemEpoxy ResinMild Steel BarStainless Steel SheetsStainless Steel StripsBag Filling MachinesAsphalt PlantsSlat ConveyorOintment PlantPlanetary MixersLadies KurtisLed LightsCctv CameraBall ValveAnti Cancer MedicineAir CompressorIncense SticksSolar LightsGoods LiftsVitrified TilesStainless Steel CoilsPvc PipesPvc Pipe FittingsUpvc PipesUpvc Ball ValvePipe Elbows