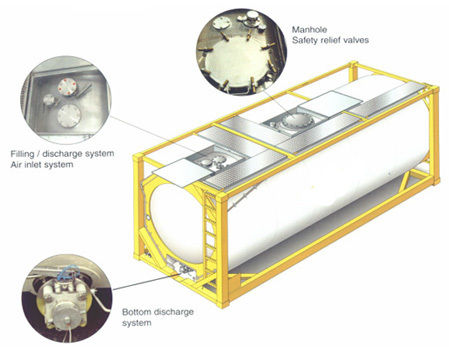

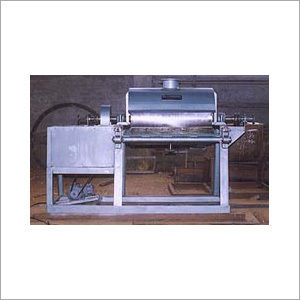

Industrial Reactor Vessel The Chemical Industry is the fastest industry. It's main section are Petrochemicals, Fertilizers, Refineries, Dyes and Intermediates etc. The industry grown substantially and has been aided largely by mechanical technology and sophisticated Equipments. For handling and Storing of large quantity of liquids and Gases a container called vessel is used and it is a basic part of process equipment. We Fabricate the vessel according to the customer's specification for Design, Fabrication, Inspection, Testing and Operation of Pressure vessel from Mild steel, Stainless steel, Boiler quality, Aluminum or of cast iron. Ome strode into new era with a relatively high-minded growth plan to provide a complete range of vessel and reactors under one roof. Every vessel and reactor has provided high efficiency Agitator devices to achieve high productivity. Drive unit consisting of three phase Motor, Gear box, V-belt drive. Lantern stool houses self aligning ball bearings. Direct coupled geared motor is also provided as an alternatives. Our Standard size of vessels & Tanks are having maximum capacity around 100 KL at Factory Premised & in Different Varieties Such as With Both dishes ends With flanged or welded topWith or without jacketWith open topWith Flat BottomWith Limpet CoilWith any Internal Coil Materials: Boiler Quality, Mild Steel, Stainless Steel, Aluminum, M.S.R.L, M.S. Lead Bonded vessels.