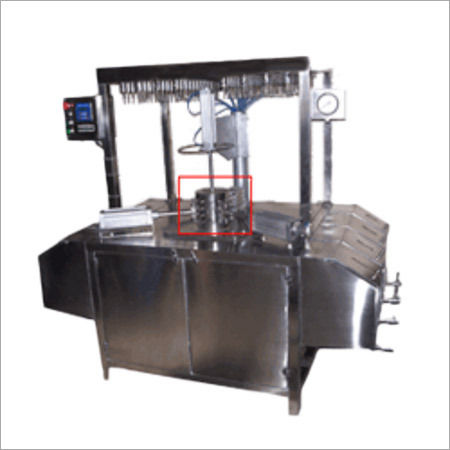

Infra ColorMain advantages: Crease- and spot-free sample dyeing.Knitted and woven fabrics as well as yarn can be dyed.Cotton, wool and synthetic materials.State of the art process controller with largeIntegrated program memory.Low liquor ratio: 1:5 fabric dyeing cotton.Stainless steel cabinet.Soda ash adding without opening the beakers.No glycerin or cooling water needed.Very good price / performance value. Simple operation: Filling dye liquor and textile.Optional: liquid chemical to be added later on during the dye process.Simple fixation of the beakers into the machine.Calling of the dye program from memory and starting the dye process. Beaker support: Three-dimensional movement and 360 rotation (clockwise andCounterclockwise) allow even and dyed through samples.The multifunctional beaker holder allows the use of different beaker sizes.Depending on structure and kind of the material to be dyed, the rotationalSpeed can be varied between 1 and 50 rotations per minute. Beaker sizes can be accommodated in 12 x 250ml model: 1000 ml x 04 beakers500 ml x 6 beakers250 ml x 12 beakers75ml x 12 beakers100 ml x 12 beakers150 ml x 12 beakers200 ml x 12 beakers Beaker sizes can be accommodated in 18 x 250ml model: 1000 ml x 08 beakers500 ml x 12 beakers250 ml x 18 beakers75ml x 18 beakers100 ml x 18 beakers150 ml x 18 beakers200 ml x 18 beakers Temperature measuring: The measuring of the temperature takes place inside the beakers allowing the direct measurement of the dye liquor. This enables the machine to accurately control and regulate the temperature. Heating system: The laboratory dye machine is equipped with four 0.75 kW or 1 kW (max.) infrared heating tubes.Maximal temperature: 140 C.Heating rate can be varied between 0.5 C/min and 4 C/min. Cooling system: Air cools down to the required temperature. The machine does not need any cooling water. Process controller: DP-02 dyeing controller Display showing dyeing process steps, temperature and rotation direction.50 programs with 32 process steps can be stored inside of the controller memory. Options: Chemical adding system: Into the specially designed chemical add systemLiquid chemicals can be filled. During the dye process, the chemical can be directly injected in to the beaker which is automatically added to the dye bath. Therefore the beakers do not have to be opened during the dye process. This allows even dyeing since during dosing the movementof the beaker continues very shortly after the dosing start.The standard beaker holder has 12 ,18 and 24 positions. To dye yarn we suggest our yarn holder. This accessory is available with extra cost with all combination of beakers.Loose stock carrier is also available for dye crease sensitive and delicate materials like silk, wools etc.Graphical display touch screen controller can also provide on request. Technical Specifications Model 12X250ML 18X250ML 24X250ML Heating INFRA RED RAYS INFRA RED RAYS INFRA RED RAYS Cooling BY AIR BY AIR BY AIR Heating power 3KW 3KW 6KW Cooling power 1/10HP MOTOR 1/10HP MOTOR 1/10HP MOTOR Drive power 1/4 HP 1/4 HP 1/2 HP Rotation (rpm) 0 TO 50 0 TO 50 0 TO 36 Automation DP-O2 DP-02 DP-02 Max.temperature 145 DEGREE 145 DEGREE 145 DEGREE Max.rate of heating 4 DEGREE 4 DEGREE 4 DEGREE Max.rate of cooling 2.5 DEGREE 2.5 DEGREE 2.5 DEGREE Material of beaker S.S 316L S.S 316L S.S 316L Machine body S.S 304 S.S 304 S.S 304 Electric supply 230V, 1PHASE,16A 230V, 1PHASE,16A 415V, 3PHASE,16A Machine dimensions 500 X 650 X 770 600 X 650 X 870 720 X 680 X 990 Machine net weights 110KGS 135KGS 155KGS Machine gross weights 175KGS 210KGS 225KGS