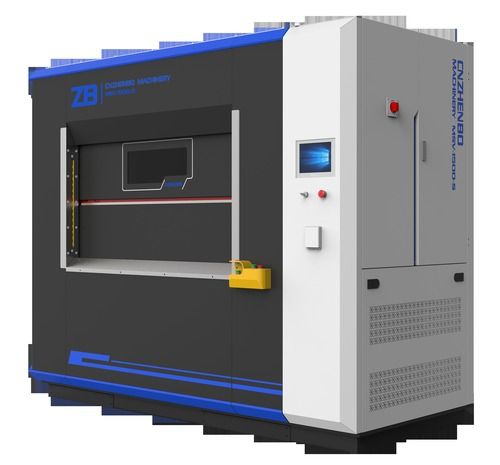

Infrared Plastic Welding Machine Dimension(l*w*h): 1490*1470*2450 Millimeter (Mm)

Price Trend: 1.00 - 60000.00 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Usage | Thermoplastic infrared joining. |

| Weight | 1600 Kilograms (kg) |

| Function | Thermoplastic welding |

| Condition | New |

| Voltage | 380 Volt (v) |

| Input Current | 55A |

| Type | Infrared, Vertical Type |

| Dimension (L*W*H) | 1490*1470*2450 Millimeter (mm) |

| Power | 20K Watt (w) |

| Motor Type | Servo Motor |

| FOB Port | Ningbo |

| Supply Ability | 20 Per Month |

| Delivery Time | 30 Days |

| Packaging Details | Wooden Case |

| Main Domestic Market | All India |

| Certifications | CE & ISO |

Product Overview

Key Features

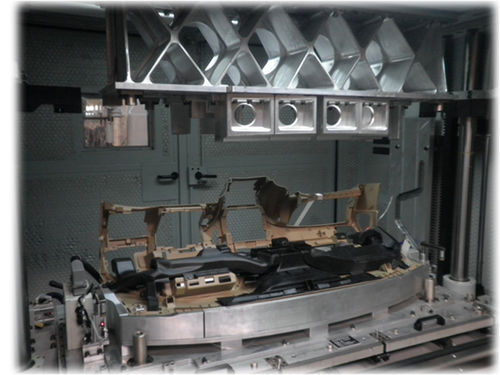

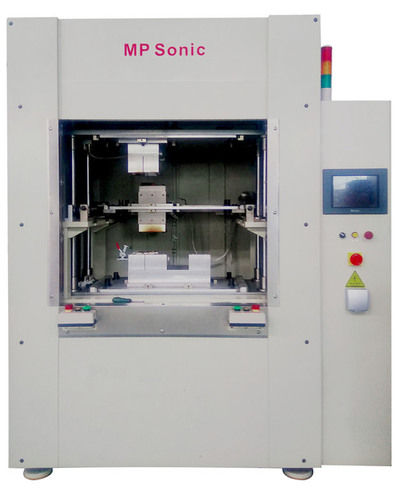

MP-Sonic supply infrared plastic welding machine and tooling for plastic welding. MP-SONIC designed infrared heating control system controls temperature through changing input voltage value, ensuing fast action in accuracy and infrared stability. MP-SONIC infrared control system can be applied for hot platen welding process control also. Machine action is controlled by servo motor in fast speed and high precision.

MP-SONIC infrared plastic welder is welcomed for the welding assembly in automotive industry, home-appliance industry, etc.

Advantages of Infrared Plastic Welding:

1.Non-contacting welding, no phenomenon of molten material sticking heat tooling;

2.Low power consumption, since the heating power is on only when melting, then it just about 1/3 of consumption by hot platen;

3.Efficient heating, no need of pre-heating, it can be put into welding production once power is turn on;

4.MP-SONIC designed infrared control system, the power supplied to infrared heating is continuous, the temperature control accuracy is high, and also ensures infrared system stability and duration.

Features:

1. Infrared welding in even and accuracy heating temperature control;

2. Servo controlled machine action in high capacity and precision;

3. System can be applied as both infrared plastic welding and hot plate plastic welding;

4. Quick tooling changing-over system;

5. Welding parameter storage;

6. Multiple safety protection including alarm system, safety door system, optical fence system and automatic from door system, etc;

7. Vacuum function for upper jig and lower jig is designed;

8. Clamp system is designed for jig;

9. Ejection system is designed for finished parts;

10. Machine action guide in high precision;

11. Air tank is designed for stable air supply;

12. Applies parts imported from Europe and japan, ensuring machine precision, stability and duration.

MP-sonice also supply infrared welding system for filter core welding (cap and filter paper welding). MP-sonic can design make customized infrared welding equipment. We provide parts design guide and analysis in free.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

50

Establishment

2012

Working Days

Monday To Sunday

Payment Mode

Cash Against Delivery (CAD)

Related Products

Explore Related Categories

Seller Details

Wenzhou, Zhejiang

Commercial Director

Mr Alex Lee

Address

No 289, Weiqi Road, Yueqing Economic Development Zone, Wenzhou, Zhejiang, 913303025905963412, China

Report incorrect details