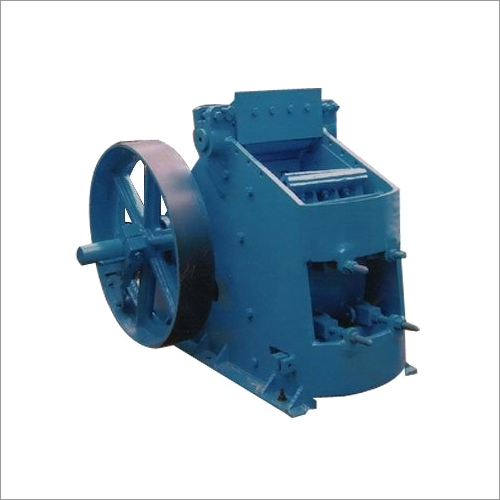

Jaw Crusher - Heavy Steel Frame, Manganese Steel Jaw Plates | Low Maintenance, Efficient Crushing For Tough Materials

Price:

Get Latest Price

In Stock

Product Overview

Key Features

Jaw Crushers are heavy duty double toggle machines designed for longlife service and minimum of maintenance for hard tough and / or abrasive material.

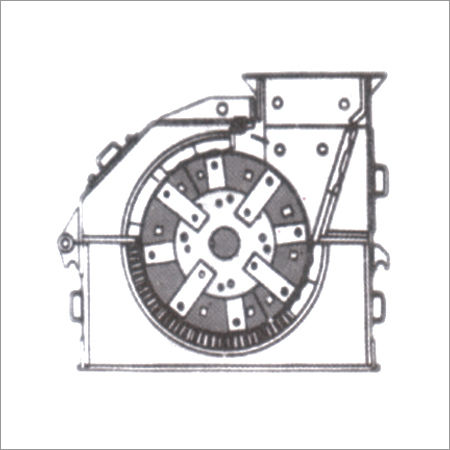

WORKING PRINCIPAL :-

The pitman shaft/electric shaft mounted in pitman imparts motion to moveable jaw plate mounted on hinged swing leve/swing jaw by means of toggle plates. The location of swing lever hinge point is correctly located to do crushing without rubbing.

STANDARD SPECIFICATION :-

FRAME(BODY): The frame is made of heavy steel plates with reinforce members welded in place. It is fabricated as a unit with all bearings seats in place and stress relieved.

SWING JAW (SWING LEVER): The swing jaw is either M.S. fabricated or C.I. and machined to accommodate swing jaw bearings and front toggle seat.

SWING JAW PIN & SUSPENSIION: The swing jaw pin is made of medium carbon steel. It is seated and clamped to the main frame. The swing jaw is freely pivoted on the shaft.

PITMAN: Pitman is fabricated from M.S. plates alternatively in one pieve casting duly normalized. The pitman is machined to receive large size antifriction bearings and provision is made for grease lubrication. Sealing covers are provided to retain grease and exclude dirt. Recesses are provided in the bottom for centre toggle seats.

PITMAN SHAFT: The pitman shaft or eccentric is special steel (Railway Axle) and machined all over to suit the bearings. The ends are key seated for fly wheel and fly wheel sheave.

PITMAN SHAFT BEARINGS AND BLOCK: Pitman shaft bearings are double row spherical roller bearings. These block are clamped to the frame and provision is made for grease lubrication covers are provided to retina lubricant and exclude dirt.

JAW PLATES: Jaw plates are of non-choking design reversible and of Manganese steel containing 12 to 14% manganese conforming to IS276. they are clamped in position.

SIDE PLATES: M.S. side plates are machined and are provided to act as protection for main frame against any wear due to material being crushed in crusher mouth.

TOGGLE SYSTEM: The toggle system rod/rods and spring is attached to the bottom of the swing jaw and crusher body/frame to keep the swing jaw and toggle system tight.

PRODUCT SIZE SETTING: By advancing rear toggle plate by lowering wedge block the setting can be reduced.

FLY WHEEL AND FLY WHEEL SHEAVE: The components are made of C.I. and keyed to the pitman shaft. The wheels are statically balanced.

LUBRICATION: Crusher is arranged for grease lubrication. Provision for lubricating bearings is provided. DRIVE: The drive to crusher is by means of one set of 'V' belts prime mover can be electric motor/diesel engine.

Company Details

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

30

Establishment

1993

Working Days

Monday To Sunday

GST NO

07DDQPM4075P1ZM

Payment Mode

Online Payments (NEFT/RTGS/IMPS)

Related Products

Explore Related Categories

Seller Details

GST - 07DDQPM4075P1ZM

Delhi, Delhi

Director

Mr Ashok Mittal

Members since

3 Years

Address

KH.NO-78/38/1, OLS 517 GROUND FLOOR, VILLAGE BAKOLI, Delhi, Delhi, 110036, India

jaw crusher in Delhi

Report incorrect details