Kemphos-822 (Self Accelerated Wire Drawing Zinc Ph

Price:

Get Latest Price

In Stock

Product Specifications

| Color | Blue |

| Chemical Composition | Zinc Phosphates |

| Odor | Pungent |

| Foaming | Nil |

| PH | Acidic |

| Toxicity | Nil |

| Coating Weight | 8-11gm/m2 |

| Features | Corrosion resistance, Friction reduction, Improved lubrication, Enhanced durability, Cost effective, Easy application, Self-accelerated |

Product Overview

Key Features

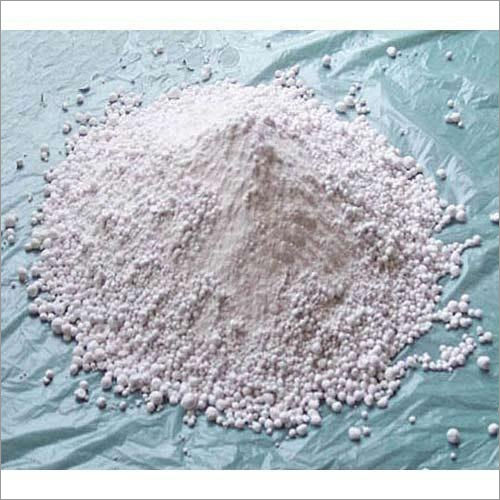

Kemphos-822 (Self Accelerated Wire Drawing Zinc Phosphating Chemical)

(Self acclerated wire drawing zinc phosphating chemical)

Product Description

Kemphos-822 is a heavy zinc phosphate compound which produces excellent zinc/iron phosphate coating on Iron and steel supplementary finishes. This product does not accelerator addition in the bath periodically. The conversion coating produced with Kemphos-822, when used in conjunction with suitable lubricant, reduces friction under low medium and high carbon forming on steel, cold shaping, drawing of wire. Lubricants and drawing compounds become firmly anchored to the phosphate coating for improved drawing.

Product Specifications

| a. | Colour | Light Green liquid |

| b. | Chemical Composition | Blend of zinc & Nickel metal phosphates, Nitrates and additives |

| c. | Odour | Slightly Pungent |

| d. | Foaming Tendency | Nil |

| e. | Reliability | Good |

| f. | Handling | Avoid Skin Contact |

| g. | Solubility | Good |

| h. | pH | Acidic range |

| I. | Toxicity | Nil |

| j. | Flash Point | Nil |

| k. | Pollution Hazard | Moderate |

| I. | Coating Weight | 8 -11gm/m2 |

Product Operating Data

| Concentration | 3% by v/v |

| Temperature | 70 - 80oC |

| Time | 7 -15 min |

| T.A. | 20 - 25 ml (3% solution) |

| F.A. | 4 - 4.5 ml (3% solution) |

| Acid Ratio | 5.0 - 5.5 |

Product Operating Procedure

Pickling

Pickling should be carried out either in sulphuric or hydrochloric acid, in combination with suitable acid inhibitors in sufficient strength to remove rust and scale present on the work.

Rinsing

The stage rinsing should be followed after pickling process, first rinse with cold water and finally rinsed with jet pressure. The rinsing tank should be cleaned regularly.

Fill the tank 2/3 with water and add recommended qty. of Khemphos-822. Fill th tank to the operating level with water and mix thoroughly. There for total acid and if necessary and enough Kemphos-822 to bring total acid to operating level and mix thoroughly. After phosphating with Kemphos-822, the work should be rinsed with continuous flowing water and subsequently once again rinsed in hot neutralizing and dried. The neutralizing solution is made up with 0.1 kg. Of soda ash per 100 litres of bath.

Operating Recommendation

Proper rinsing is very much essential after pickling in mineral acids in order to remove residues from the surface of the work. Any carry over of the acid to the phosphating tank will lead to excessive sludge formation deterioration of phosphate coating and high chemical cost.

- Proper control of temperature, pointage and time minimise the chemical consumption.

- Thin coating may result from a low bath temperature and insufficient treating time.

Product Application Equipments

Kemphos-822 tank should be fabricated with 3 to 4 mm thick M.S. Plates with continuous convection current hating system.

6.0 Testing and Control Procedure

The Kemphos-822 is controlled by simple titration for total acids. Ferrous Iron concentration of Kemphos-002 (Accelerator) by titration method.

Total Acidity

Pipette out 10 ml of bath solution into a beaker. Add 5 -10 drops of indicator Phenolphthalein. Fill the burette to the zero mark and titrate with N/10 sodium Hydroxide solution. Stir the solution until pink colour appears. Note volume of N/10 sodium hydroxide solution used.

Free Acidity

Pipette out 10 ml. Of bath solution into a beaker. Add 5 -10 drops of bromophenol blue Indicator. Fill the burette to the zero mark and titrate with N/10 sodium hydroxide solution. Stir the solution until blue violet colour appears. Note volume of N/0 sodium Hydroxide solution used.

Chemical Replenishment

Add 125 ml. Of Kemphos-822 per 100 ltrs. Bath for each point lacking. The bath should be kept with in 1 ml. Of the specified titration values.

During the processing sludge is formed and the same is accumulated in the bottom of the tank. It should be removed at regular intervals. Sludge removal is carried out by decanting the clear solution in a emptied tank. Clean the phosphating tank and returned to the decanted solution. The bath solution is resotred to is operating level by adding water and chemical in the recommended proportion as used in the original bath.

Safety Measures

Kemphos-822 is an acidic liquid material, and while handling proper care should be taken. Protect eyes and skin by means of goggles, aprons, gloves, etc. If it comes in contact with skin and eyes wash thoroughly with a flush of water and get medical advice.

General Information

Corrosion Resistance: Excellent

Lubrication during wire drawing: Excellent.

Company Details

Focusing on a customer-centric approach, KEMFIN CHEMICALS (P) LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Chemical Supplies in bulk from KEMFIN CHEMICALS (P) LTD. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

31

Certification

ISO 9002

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Ballabgarh, Haryana

Director

Mr. Lokesh Bhalla

Address

41 KM, Khandawali Road, Ballabgarh, Haryana, 121004, India

wire drawing powder in Ballabgarh

Report incorrect details