We Rotacon Technical Services is a company having its headquarters in Mumbai, India is an employee owned, customer focused, quality driven organization, expert in Plant maintenance services of key rotary equipment in cement, mineral, chemical, fertilizer & paper plant such as kilns, dryer, granulator, cooler, calciner and ball mills.

Our sole aim is to provide best possible services in the industry to all the esteemed customers. We are now moving one step further by providing end to end solutions in drums such as supervision and turnkey & replacement. We are well placed with very experienced specialists and extensive support of our associates in turnkey jobs.

We are also extending our support in ball mills. With very experienced mill specialists in our team, we can do ball mill inspection and repair & replacement of ball mill components on turnkey or supervision services.

We are Pro-active on safety. In Turnkey repair and replacement services, we depute qualified safety supervisor along with our specialist to ensure round the clock safely execution of job. Our team work nurtures safe work environment for our employees and sub-contractorA A A AcA A A A A A A A s workmen. We stand committed to continue doing our best by making safety a mandatory requirement for all our employees and sub-contractors workmen. Please note all our tools are certified by recognized agency and we provide mandatory safety training to all our engineers.

In present scenario of fierce competition, profitability depends upon productivity. And, for the improvement, various management systems are available. However, systematic analyzing and eliminating unscheduled breakdowns, implementing suitable corrective measures to operate the machine efficiently still remains a key parameter, to increase the productivity. In process industry, machines have to perform in synchronous with each other and breakdown in any critical machine result in reduction of the productivity. In view, it is desired to reduce / eliminate critical machines breakdown. We offer on-line drum Alignment as a preventive measure tools to increase the drum operation, mechanically. We have continuously updated and improved the method, measuring instruments and computer software to provide our clients with the best possible tools to evaluate the consequences of the drumA A A AcA A A A A A A A s present operating condition in respect of the availability.

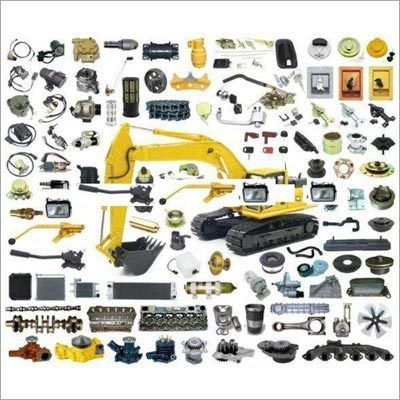

Our entire service portfolio is dedicated to helping Maintenance Managers to reduce or even eliminate unscheduled stoppages. By performing regular service checks on vital equipment, ensuring staff are trained on preventive maintenance, and providing a dependable supply of high-quality wear parts, Rotacon Technical Services helps Maintenance Managers ensure the availability of their production lines.

Shell Replacement

Tire Replacement

Supporting Roller/Bearing Replacement

Girth Gear and Pinion Reversal/Replacement

Thrust Roller Replacement

Inlet/Outlet seal Replacement

Supporting roller adjustments for thrust correction (During Operation)

Solving of Hot bearing issue (During Operation)

Vibration at drum drive station (During Operation)

Hot kiln alignment

Cold alignment of drums