Gear Boxes, Reduction Gears & Gear Cutting

(8094 products)Spur Gear - EN 24 Steel, 50mm Diameter, 36 Teeth, Silver Color | Durable, Cost-Effective, Hobbing Processed

Price Trend: 100.00 - 250.00 INR/Piece

MOQ1 Piece/Pieces

Gear TypeSpur Gears

MaterialSteel

Processing TypeHobbing

Gear Tooth ProfileOther

Gearing ArrangementSpur

Emco Engineering

Mumbai

Super Bonanza

Super Bonanza6 Years

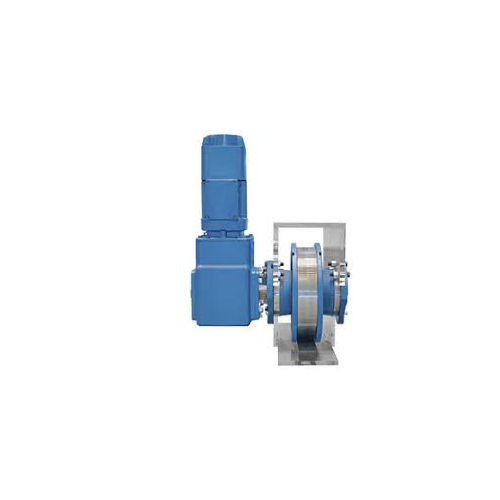

Hydraulic Planetary Gear Boxes Body Material: Stainless Steel

Price Trend: 10000.00 - 100000.00 INR/Unit

MOQ1 Unit/Units

Product TypePlanetary Gear Boxes

Body MaterialStainless Steel

TypeMotor

Voltage380 Volt (v)

United Hydraulic Control

Ahmedabad

19 Years

Worm Gear Pairs

Product DescriptionWe are manufacturing, exporting and supplying our client an excellent quality range of Gear Pairs in Ahmedabad, Gujarat, India. Gears operate in pairs and modify rotary motion and torque without slip. These Gear Pairs are superior in quality and serve for years with minimum maintenance required. We

Air Vac Equipment

Ahmedabad

18 Years

Girth Gears - Up to 8500mm Outer Diameter, 75 Module - Spur, Helical, & Double Helical Configuration for Diverse Industrial Applications

Product DescriptionTechnical Parameters of Girth Gears :- Capacity: Up to 8500mm Outer Diameter, 75 Module (Multi Segments) Type: Spur, Helical, Double Helical Common Application: Various equipments used in industrial sectors such as ,Cement Plants, Sugar Mills, Sponge Iron Plants Fertilizer plants, Thermal Power Stat

Ashoka Machine Tools Corporation

Greater Noida

21 Years

Helical Gear Box - Mild Steel, 20 Nm Output Torque, 220-415 V, 1440 RPM Speed, 85% Efficiency, Spur Gears, Clockwise Direction, Blue Color, 0.5HP Rated Power

Price Trend: 13500.00 - 550000.00 INR/Box

MOQ1 Number

Weight15 Kilograms (kg)

Product TypeGEARBOX

ColorBLUE

UsageINDUSTRIAL

Gear TypeSpur Gears

MaterialSteel

J. D. Automation

Pune

10 Years

Super Premium

Super PremiumMechanical Gears - Cylindrical/Disk Design, Radial & Parallel Involute Teeth, Enhanced Durability & Corrosion Resistance, Low Friction & High Torque Efficiency

Product DescriptionThese Mechanical gears offering by us are in cylindrical or disk type designs. The teeth of these gears are fitted in radials or are aligned parallel to the axis of rotation. The involute teeth are parallel to the shaft to connect them in parallel form. Thus avoiding any formation of external thrust

Esspee Engineers

Kolkata

11 Years

Shimpo Vrt Series Servo Gearbox - Color: Silver

Price: 15000 INR/Piece

MOQ1 Piece/Pieces

UsageIndustrial

ColorSilver

Product TypeShimpo Vrt Series Servo Gearbox

MaterialStainless Steel

Output Torque0.03 N-m

Input Speed8000 RPM RPM

Amess Controls Pvt. Ltd.

Ahmedabad

4 Years

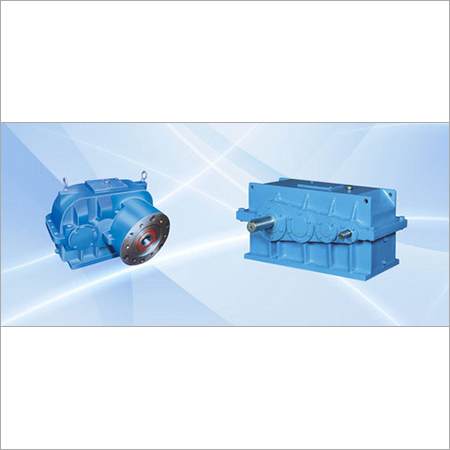

Industrial Helical Gearbox - Iron Build, Available Sizes, Blue Finish | Bevel Gears for Versatile Industrial Usage

Price Trend: 50000-500000 INR/Unit

MOQ1 Unit/Units

SizeSizes Available

UsageIndustrial

Product TypeHelical Gearbox

ColorBlue

Gear TypeBevel Gears

MaterialIron

Vidhya Trading

Vadodara

9 Years

Black Sintered Gears

Price: 11.05 INR/Piece

MOQ5000 Piece/Pieces

ColorBLACK

UsageINDUSTRIAL

Product TypeMAINTAINANCE FREE PRODUCT

MaterialSINTERED IRION

FinishFULLY FINISHED

LubricatingSELF LUBRICATING

Oilite Industries

Kolkata

8 Years

Gear Box & Motors

Product DescriptionWide range of Gear Box & Motors for various application and industries\015\012Range:\015\012\015\012Induction Motor, Synchronous Motor, Brake Motors, Crane & Hoist Duty Motors, Textile Motors, Ring frame motors, Carding Loom motors, Dual & Multiple Speed Motors, Lift Duty Motors, Inverter Duty Moto

Labh Projects Pvt. Ltd.

Ahmedabad

6 Years

Spiral Bevel Gear Box - Premium Quality Raw Material, Corrosion Resistant Finish, Reliable Operations, Adaptable and Fixed Foot-Mounted Types

Product DescriptionThe range of spiral bevel gear box we offer to clients are used when the direction of shaft's rotation is to be changed. We make use of best quality raw material in manufacturing the products to ensure their superior functioning at longer time period.\015\012\015\012Our product range is known for

Ugi Engineering Works Pvt. Limited

Kolkata

23 Years

Planetary Gear Box - Stainless Steel, Gray Color | Industrial Use, 280 Voltage, Planetary Gearing Arrangement

Price: 20000 INR/Unit

MOQ1 Unit/Units

ColorGray

Product Typeplanetary gear Box

UsageIndustrial

MaterialStainless Steel

Gearing ArrangementPlanetary

Voltage280 Volt (v)

Nano Technologies

Chennai

6 Years

Iron Helical Bevel Gear Unit

Gear TypeBevel Gears

MaterialIron

Gear Tooth ProfileHelical Gear

Gearing ArrangementHelical

Nord Drivesystems Pvt. Ltd.

Pune

15 Years

Gearbox Assembly - Color: Blue

MOQ1 Piece/Pieces

SizeSizes Available

UsageIndustrial

ColorBlue

ConditionNew

Product TypeGearbox Assembly

Warranty1 Year

Silverline Metal Engineering Pvt. Ltd.

Mumbai

18 Years

SMSR (D-J)

Main Export Market(s)Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Main Domestic MarketAll India

Silver Nord Universal Si Worm Geared Motor

MOQ1 Piece/Pieces

UsageIndustrial

ColorSilver

Size6

Product TypeWorm Geared Motors

Gear TypeWorm Gears

MaterialOther, Cast Iron, Mild Steel, Stainless Steel

Dynamic Products

Mumbai

7 Years

Helical Gear Usage: Industrial

Price Trend: 100-150 INR/Unit

MOQ1 Unit/Units

UsageIndustrial

B V Transmission Industries

Mumbai

6 Years

En353 Drum Gear Box - Efficiency: High

Price: 70000 INR/Unit

MOQ1 Unit/Units

UsageIndustrial

Product TypeDrum Gear Box

SizeDifferent Available

MaterialStainless Steel

EfficiencyHigh

Shree Adarsh Enterprises

Indore

4 Years

Low Oil Level Switch For Gear Box

Product DescriptionOil level of the gear box is an important parameter to be monitored. Damages expected due to low oil level are obvious and need not to be elaborated. Old float type switches rely on buoyancy of the oil which changes with the impurities in the oil. Trip level also depends on the strength on the magne

Acd Machine Control Company (p) Ltd.

Mumbai

9 Years

SS Servo Gearbox - High-Efficiency Stainless Steel Construction, Various Sizes Available - Durable Spur Gear Design for Industrial Applications

MOQ10 Unit/Units

UsageIndustrial

SizeVarious Sizes Available

Gear TypeSpur Gears

MaterialStainless Steel

Processing TypeForging

EfficiencyHigh

Cess Automation India Llp

Ahmedabad

2 Years

PBL Industrial Planetary Gearbox - Stainless Steel, Green Color | High Efficiency, Heavy Duty Torque Transfer

Price: 25000 INR/Box

MOQ1 , Box/Boxes

ColorGreen

UsageIndustrial

Product TypePBL Industrial Planetary Gearbox

MaterialStainless Steel

Bisu Transmission

Vadodara

4 Years

Helical-Worm Gear Units

Product DescriptionSEW-EURODRIVE helical-worm gear units are helical/helical-worm combinations so that they have greater efficiency than plain helical-worm gear. Due to their outstanding profitability, these drives can be used in every industrial sector and tailored individually to individual torque and speed requirem

Lakshmi Electro Controls & Automation

Bengaluru

19 Years

CHENYUE Worm Gearbox CYWF80 speed ratio from 5:1 to 100:1 free maintenance, fully sealed, No need to refuel for life

Price: 958.99 USD ($)/Piece

MOQ3 Piece/Pieces

Size30.5*29.5*38

Height38 Centimeter (cm)

Weight24.9 Kilograms (kg)

Length30.5 Centimeter (cm)

Product TypeCYWF80 7.5 KW Worm Gearbox

Usageindustrial

Chenyue (jiangsu) Technology Co., Ltd.

Suqian

2 Years

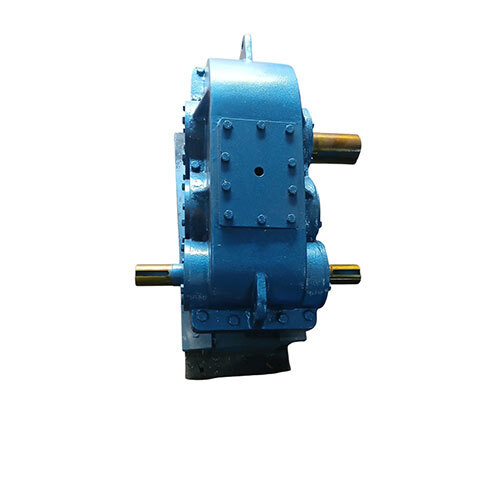

Parallel Helical Gearbox - Steel Material, Blue Color | Heavy Duty for Industrial Gantry Crane with Helical Gear Tooth Profile

Price: 65000 INR/Piece

MOQ1 Piece/Pieces

Product TypePARALLEL HELICAL GEARBOX FOR HEAVY DUTY GANTRY CRANE

UsageIndustrial

ColorBlue

MaterialSteel

Processing TypeOther

Gear Tooth ProfileHelical Gear

Gamma Gears

Ahmedabad

4 Years

Stainless Steel Gearbox

Price: 9500 INR/Unit

MOQ1 Unit/Units

ColorBlue

Product TypeGear Box

MaterialStainless Steel

Rated Power200 Watt

Input Speed2800 RPM

Voltage200-240 Volt (v)

Nbe Motors Pvt. Ltd.

Ahmedabad

19 Years

Ball Bearing - High-Quality Steel, Precision Engineering | Durable, Reliable Performance, Versatile Applications

Product DescriptionWe are one the leading manufacturer, exporter and supplier a myriad collection of Ball Bearing in Ahmedabad, Gujarat, India. It is manufactured by our adroit professionals using outstanding quality raw material that is sourced from the most trusted and dependable vendors of the industry. One can ava

Belt And Bearing House Private Limited

Ahmedabad

5 Years

Warm Gear - Quality Fabric Blend, Multiple Sizes Available , Durable and Lightweight Design

Payment TermsTelegraphic Transfer (T/T), Paypal, Others, Western Union, Cash Against Delivery (CAD), Cash in Advance (CID), Cheque

Delivery Time1 Week

Sample PolicyContact us for information regarding our sample policy

Patel Overseas

Rajkot

2 Years

Quarter Turn Gearboxes Application: The Electrical Actuator Is An Electro Mechanical Device Which Mainly Used In Control The Flue Gases.

Price: 200000 INR/Unit

MOQ1 Unit/Units

ApplicationThe Electrical Actuator is an electro mechanical device which mainly used in control the flue gases.

Protection LevelIP65

Frequency (MHz)50 Hertz (HZ)

Marsh Automation Pvt Ltd.

Pune

5 Years

Latest From Gear Boxes, Reduction Gears & Gear Cutting

Spur Gear

By:

Mahalaxmi Engineering Corporation

Stationary Concrete Mixer Drive

By:

Planetary Gear India Pvt. Ltd.

Bevel Planetary Speed Reducer

By:

Kavitsu Transmissions Private Limited

Warm Gears

By:

Shree Mahalaxmi Marketing

Worm Gear Box

By:

Entell Cad Engineering

Explore More Cities

Ready To Ship Gear Boxes, Reduction Gears & Gear Cutting

The Different Types of Gearboxes, Reduction Gears & Gear Cutting

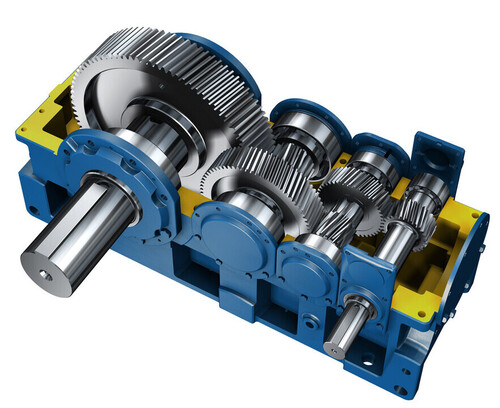

The gearbox is a vital component of machinery employed in many fields. A reduction gear consists mostly of a system of gears that are linked to various components of a wheel. The set of gears spins, transmitting the incoming motion, and that too at high speed.

Gear box types:

1. Skew Bevel Helical Gearbox

The skew bevel helical gearbox is robust and may be used in a variety of settings due to its one-piece design and ability to support substantial loads. The mechanical advantages of these industrial gearboxes become available once they are installed on the suitable motor shaft output.

2. Bevel Helical Gearbox

There is a set of curved teeth on the cone-shaped surface of this gearbox, just around the rim. To produce rotational motion between shafts that are not parallel, the bevel helical gearbox is employed.

3. Coaxial Helical Inline Gearbox

As its name suggests, the coaxial helical gearbox is best used in situations when high levels of power and efficiency are required. Coaxial helical inlet lines are well-known for their high quality and efficiency.

4. Helical Gearbox

In terms of size and power consumption, the helical gearbox is quite efficient. Although this machinery has many potential industrial applications, its primary function is to do demanding jobs.

Reduction Gear Types:

1. Single reduction Gear

The reduction ratio of a single gear set is achieved by a pair of gears in a simple design. The reduction gearbox has individual entry points for the propeller shaft and the engine shaft. In addition to the main gear on the propeller shaft, the assembly features a smaller gear known as a pinion, which is turned by the engine's incoming shaft.

2. Double Reduction Gear

When a high rate of speed is required, a double reduction gear is employed. The pinion in this double-reduction gear set is coupled to the input shaft (combines with a flexible coupling connection). An intermediate gear is linked to the primary reduction gear. A pinion coupled to a low-speed shaft is what makes this first reduction gear work. The reduction gear attached to the propeller shaft is linked to this pinion.

Gear Cutting Types:

1. Gear Milling

Here, a form cutter on a milling machine is used to conduct the actual gear cutting. This cutter rotates along an axis to create gear teeth of uniform length and profile. Once a tooth has been cut, the cutter is taken out of the gear blank so it can be rotated to the next position.

2. Gear Hobbing

In the production of Gear Boxes, Reduction Gears & Gear Cutting, the method known as "hobbing" is used because of its speed and convenience. For hobbing gear teeth into blanks, the machine employs a helical cutting tool, or hob. As a result of its efficiency, this method is well suited for mass manufacturing at the medium- to high-level.

3. Gear Broaching

When creating internal gears or splines, broaching is the best method. It's important to utilize the right broaching tool for the job. The versatility of CNC lathes, mills, machining centers, and other turning machinery makes rotary broaching an attractive option for producing gears.

4. Gear Grinding

Gear grinding is another manufacturing method. When working with a gear blank, gear grinding is done to smooth out any rough spots by rubbing away surface material. The excess metal in the gear is removed by rubbing a rough surface against a piece of metal at high speed.

What Are Gears And Gearboxes.

There are many different kinds of gears that can be used inside of a gearbox, including but not limited to bevel gears, spiral bevel gears, wormgears, and planetary gears. Rolling element bearings support and rotate the shafts onto which the gears are placed. The gearbox is a mechanical energy converter that decreases the vehicle's velocity while raising the torque.

Simply put, a gearbox is a mechanical component that includes a set of synchronized gears, shafts, bearings (to support and resolve loads), and, in many cases, a flange for mounting a motor.

Main Functions of Gearboxes And Reduction Gears

1. Get Ratio

Using the gear ratio, one can quantify the interaction between gears of varying sizes and the amount of energy transferred. An important part of gears is circles, and so the circle measurement is the heart of this calculation. The gear ratio is found by measuring the diameter of a circle. If a smaller gear must make two revolutions to spin a larger gear once, the ratio between them is 2:1, and the output speed is reduced by half. Reducers that use a succession of gear pairs to transform RPM into torque are made easier to understand by this illustration.

2. Gear Reducer Torque

The gear reducer takes in torque, which is a rotational force, and converts it into a different force and speed while maintaining the same amount of power.

When the number of revolutions per minute (RPM) of a motor is decreased, the torque it produces increases. Gear reducers, either mounted on the base or the shaft, make this possible.

The ratio between gear teeth determines the amount of torque that can be multiplied or divided. The fundamental principle of a gear box is that the torque can be increased or decreased depending on the ratio of the gear sizes.

3. Drive Gear

Gear drives, often known as drive gears, modify the rotational velocity, torque, or axis of a shaft. They are, at their most fundamental, a small gear attached to the output shaft that turns a larger gear.

It's impossible to have variable output speed from a constant power source without them. The worm gear set's driven gear is the brass-colored worm wheel.

4. Driven Gear

The output shaft is linked to the driving gear, which then transfers the reduced power to the load. They occur in a variety of shapes, but regardless of the number of gears in a set, they are always the largest.

Two driving gears (A and D) are each attached to a separate shaft (B and C) in the compound gear train diagram. For both shafts B and C, the driving gear has the same gear ratio.

Difference Between Reduction Gears & Gear Cutting

Reduction Gear

Reduction gearboxes, also known as speed reducers, are used to lessen the input speed from the motor while increasing the output torque. The apparatus is used to convert the rotations of the basic engine's output shaft into those required to turn the propeller. The reduction gearbox is home to the wheels and pinions with interlocking teeth responsible for transferring power from the drive shaft to the driven shaft at a lower velocity.

To slow the motor's output, it is coupled with a reduction gearbox, which may alternatively be called a torque multiplier or speed reducer. Reduction gearboxes, which are essentially a gear train connecting the motor to the machine, are overly simplistic in design. Since the output gear is larger than the input gear, the output shaft rotates at a slower rate, generating more torque while maintaining the same speed.

Gear Cutting

Designers provide cutting technology for gears up to 3 meters in diameter. When complex gears have to be made quickly, this technology is often the preferred method.

Methods for cutting gears include the following:

- Broaching: For gears of this size and larger, a spline or vertical broach is used. The teeth form of a gear can be easily made using this. The biggest gears in the world are made with these equipment and cutters. While this method is costly, it allows for the mass production of huge gears.

- Hobbing: refers to the practice of using a hob to make cuts, specifically in the case of a tooth. In order to make one complete rotation of a given gear, the hob must be able to form all of the teeth in one revolution. Although this technique shines for medium and large production runs, it is applied for all run sizes.

- Milling or Grinding: Milling equipment or a jig grinder is used in this technique. Helical gears can be made with this.

- Shaping: Among the available methods for cutting gears, this is among the most practical. A continuous gear rotational cut in the same plane is used to accomplish this.

FAQs: Gear Boxes, Reduction Gears & Gear Cutting

Q. What are the different types of gearboxes used in industries?

Ans: Here are the types of Industrial gearboxes:

- Helical Gearbox

- Bevel helical gearbox

- Coaxial helical inline

- Worm reduction gearbox

- Planetary gearbox

Q. Difference between gearbox and gear drive.

Ans: When referring to the transmission that connects an electric motor to another piece of machinery, the word "gearbox" is used interchangeably. While the gear drive that connects a motor to the machinery are known as speed reducers. The speed reducer's job is to lessen the rotational velocity between the two terminals.

Q. What are the main components of Gearboxes and Reduction Gears?

Ans: Flywheel, Collar, Stick Shift, Clutch Disc, Synchronizers, Selector Fork, Clutch Pedal, and Gears are the common components.

Q. How gear cutting works?

Ans: Cutting gears is done on dedicated machines that are incapable of doing anything else.

Manufacturers & Suppliers of Gear Boxes, Reduction Gears & Gear Cutting

Company Name | Member Since |

|---|---|

Ugi Engineering Works Pvt. Limited Kolkata, India | 23 Years |

Ashoka Machine Tools Corporation Greater Noida, India | 21 Years |

United Hydraulic Control Ahmedabad, India | 19 Years |

Lakshmi Electro Controls & Automation Bengaluru, India | 19 Years |

Nbe Motors Pvt. Ltd. Ahmedabad, India | 19 Years |

Air Vac Equipment Ahmedabad, India | 18 Years |

Silverline Metal Engineering Pvt. Ltd. Mumbai, India | 18 Years |

Nord Drivesystems Pvt. Ltd. Pune, India | 15 Years |

K I Transpower Pvt. Ltd. Sonipat, India | 12 Years |

Esspee Engineers Kolkata, India | 11 Years |

Popular Products