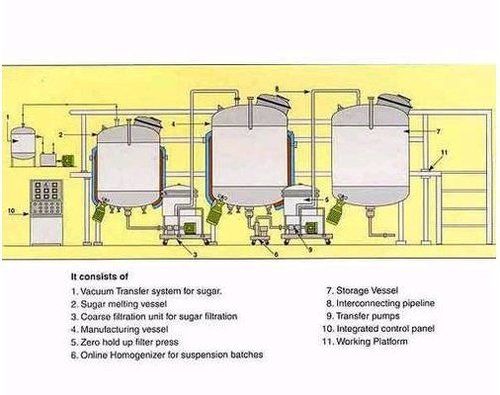

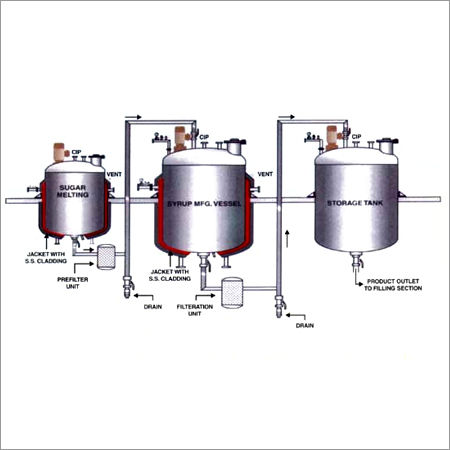

Syrup Manufacturing Plant - 500 To 15000 Liters Capacity, Stainless Steel Vessels With Vacuum Transfer System And Digital Control Panel

Price:

Get Latest Price

In Stock

Product Overview

Key Features

Sugar Syrup Vessel Online Sugar syrup prefilterManufacturing VesselStorage VesselVacuum System for transfer of sugar syrupFilter Press / Inline HomogenizerProduct PipingControl Panel

SALIENT FEATURES

The Plant is designed to be operated by one operator and one helper, saving on precious man power cost.Sugar syrup

& manufacturing vessels are provided with limpet coils for heating

and cooling, designed for internal vacuum to facilitate transfer of

sugar directly from stores to syrup manufacturing vessel.Sugar syrup is transferred to manufacturing vessel through online sugar syrup prefilter by vacuum.Entry of all propeller agitators are from bottom through a specially designed cartridge Mechanical Seal with TC/TC seal face.The advantage

of the bottom propeller agitator over the conventional agitator is that

there are no vibrations of shaft, no couplings in the drive assembly,

leading to lower maintenance cost.Pipes, pipe

fittings and valves are of SS 316 / SS 304, seamless, internally

electro polished with DIN Standard unions and silicon Gaskets.Manhole of all the vessels are equipped with davit fitting and the cover of the manhole slides instead of being fitted.

PROCESS CONTROL:

Values like

current, product temperature are displayed digitally on the electrical

control panel. The mechanical seal is equipped with a water circulating

system and has a water detection sensor which trips the motor, if the

water circulation to the seal is interrupted.

CAPACITIES: 500 LITERS TO 15000 LITERS

Disclaimer

Company Details

Capsule and Tablet Inspection Machine, Single Rotary Tablet Press, Stainless Steel Fluid Bed Dryer and others are manufactured in various specifications and in accordance with the industry standards. We are a quality conscious manufacture and strictly abide by all the industry standards while developing our range. Quality tested on various parameters, our products are carefully packed and dispatched through reliable logistics companies which have access to various modes of transportation.

Business Type

Manufacturer, Supplier

Employee Count

25

Establishment

1992

Working Days

Monday To Saturday

GST NO

24AEEFS1612L1Z5

Payment Mode

Cash Against Delivery (CAD), Cash on Delivery (COD)

Related Products

Explore Related Categories

Seller Details

GST - 24AEEFS1612L1Z5

Ahmedabad, Gujarat

Partner

Mr. Kunjan Shah

Address

B. No. 43, Plot No: 3609, Phase-IV, Vatva, Kameshwar Estate, Near Nika Tube X Road, Ahmedabad, Gujarat, 382445, India

liquid oral manufacturing plant in Ahmedabad

Report incorrect details