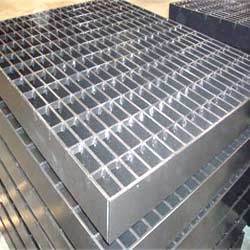

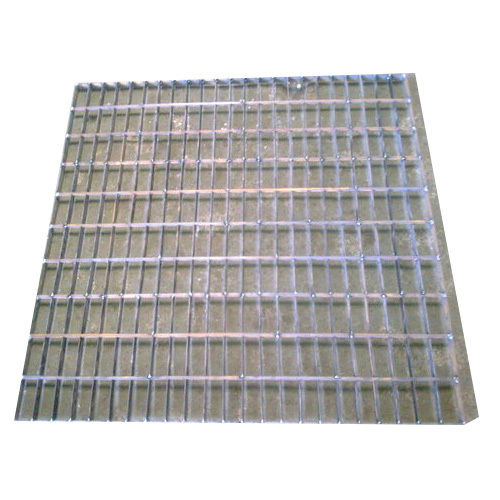

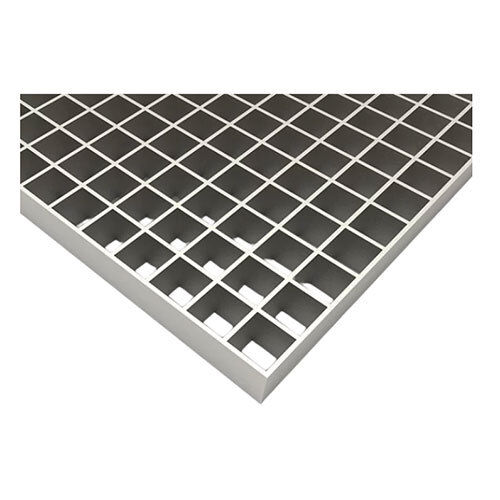

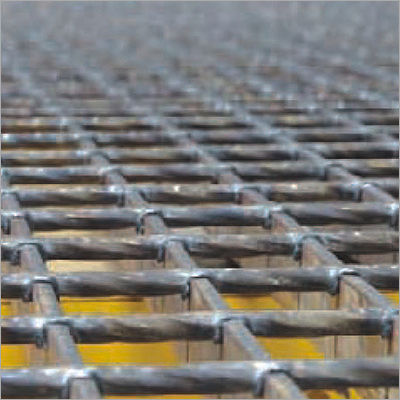

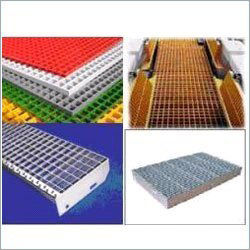

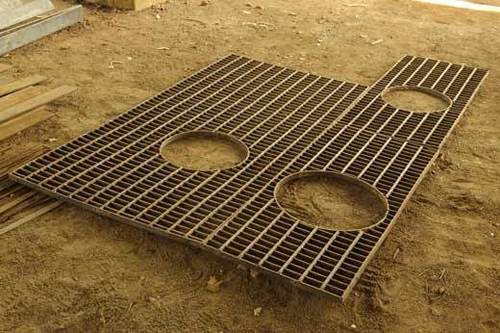

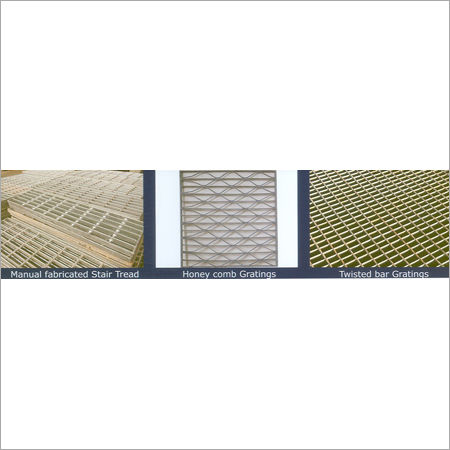

Manual Gratings

Price:

Get Latest Price

In Stock

Product Specifications

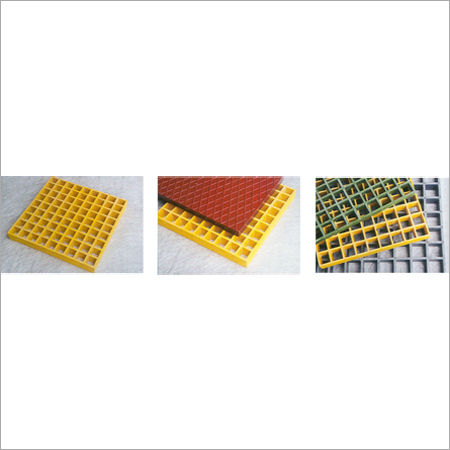

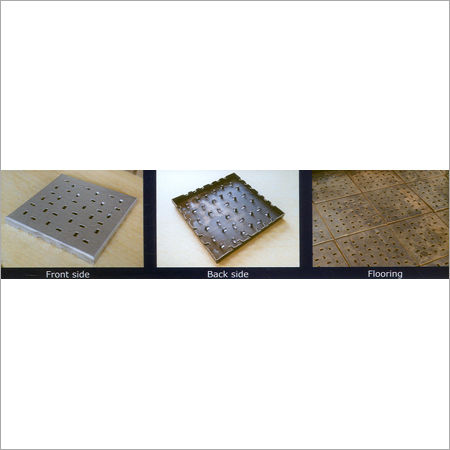

| Product Type | Heavy Duty |

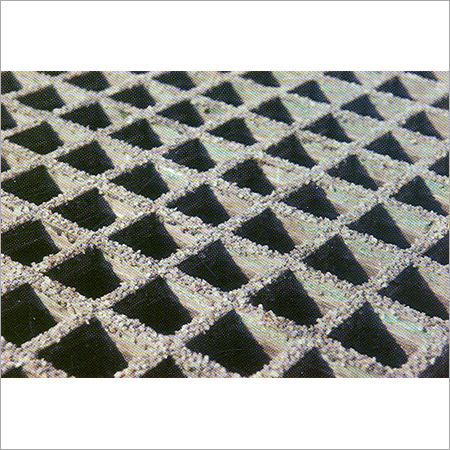

| Serrated Pattern | Available |

| Bearing Bar | 30-50 |

| Cross Bar | 50-100 |

| Interlock Pattern | Available |

| Zig Zag | Hp 40 |

| Diamond Pattern | Dp 30 |

| Features | Non-Slip, Optimum Strength, Safety, Durability |

Product Overview

Key Features

Company Details

Focusing on a customer-centric approach, Omkareshwar Engineering has a pan-India presence and caters to a huge consumer base throughout the country. Buy Grating in bulk from Omkareshwar Engineering at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

70

Establishment

2006

Working Days

Monday To Sunday

GST NO

27AADPU0285G2ZK

Certification

ISO 9001 : 2000

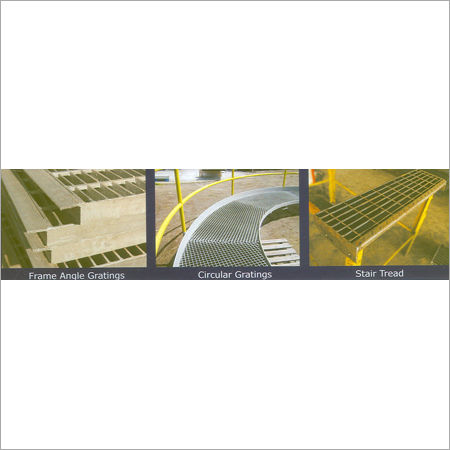

Related Products

Explore Related Categories

Seller Details

GST - 27AADPU0285G2ZK

Mumbai, Maharashtra

Director

Mr. Angad K Upadhyaya

Address

Unit B -5, Hema Industrial Estate, Sarvodya Nagar, Jogeshwari (East), Mumbai, Maharashtra, 400060, India

heavy duty grating in Mumbai

Report incorrect details