Manual Hand Press Machine 4 - 16 Inch

Price: 17152 INR / Piece

Get Latest Price

Minimum Order Quantity :

1 Piece

In Stock

Product Overview

Key Features

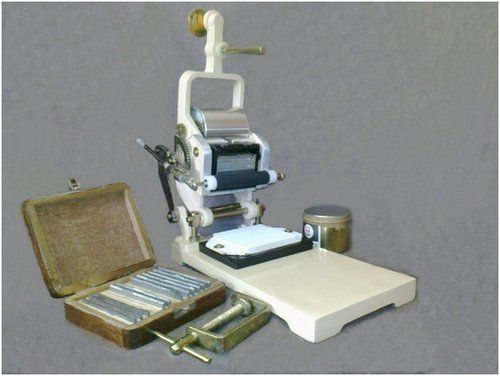

Creating a manual hand press machine for paper plate making involves a blend of engineering precision, functional design, and practicality. This intricate equipment serves as an essential tool in the production of eco-friendly disposable plates. Its purpose is to efficiently transform raw materials into finished products while ensuring ease of operation and consistent quality output.

Introduction:

A manual hand press machine for paper plate making represents a pivotal innovation in the realm of small-scale plate manufacturing. Its design revolves around simplicity, durability, and effectiveness, catering to the needs of individuals, small businesses, or community-based enterprises aiming to produce biodegradable plates. This comprehensive description aims to dissect its various components, functionalities, operational mechanisms, and the overall impact it has on the industry.

Structural Design:

The machine typically features a robust frame constructed from high-grade steel or alloy, ensuring stability and durability during the plate-making process. Its compact size and ergonomic design allow for easy maneuverability and placement within limited workspace environments. The structural integrity of the machine is crucial to withstand the repetitive pressure and movements required during production.

Functional Components:

Pressing Mechanism: The heart of the machine lies in its pressing mechanism. It comprises a lever or handle that, when manually operated, exerts controlled pressure on the raw materiala usually pulp or paper sheetsa molded into the desired plate shape and size.

Die or Mould: A key component is the die or mould set, which determines the final shape and size of the paper plates. The machine often includes interchangeable dies to produce various plate designs and sizes, offering versatility to meet different market demands.

Base Plate Platform: Beneath the pressing mechanism lies the base plate platform where the raw material is placed. This platform holds the die and provides support during the pressing process.

Supporting Mechanisms: Some machines might incorporate additional supporting mechanisms such as locking systems or alignment guides to ensure precise placement of the material and maintain consistent output.

Operational Workflow:

The operation of the manual hand press machine involves a series of systematic steps:

Raw Material Preparation: The process begins with the preparation of raw materials, typically sourced from recycled paper or pulp, which are cut into appropriate sizes to fit the die/mould for plate formation.

Die Selection and Setup: Operators select the desired die or mould and securely fix it onto the base plate platform of the machine.

Material Placement: Precut paper sheets or pulp are placed onto the base plate within the die, ensuring proper alignment for accurate plate formation.

Pressing Process: The operator then pulls the lever or handle, engaging the pressing mechanism. The applied pressure molds the material within the die, shaping it into the form of a plate.

Plate Removal: Once the pressing process is complete, the operator releases the pressure, opens the machine, and carefully removes the newly formed paper plate.

Finishing Touches (Optional): Depending on the design and specifications, additional finishing touches like edge trimming or surface smoothing may be performed manually or integrated into the machine's functionality.

Key Features and Advantages:

User-Friendly Operation: The machine's manual operation makes it accessible and easy to use, requiring minimal training for operators.

Cost-Effectiveness: Its manual nature reduces dependence on electricity, making it an economical choice for small-scale production units or areas with limited power resources.

Environmental Sustainability: By utilizing recycled paper or pulp as raw materials, the machine contributes to eco-friendly plate production, reducing the environmental impact of plastic-based alternatives.

Related Products

Explore Related Categories

Report incorrect details