Metso Ufs 6 1800 To 3600 Rpm Ultra Fine Screens Screening

Price:

Get Latest Price

In Stock

Product Specifications

| Payment Terms | Telegraphic Transfer (T/T), Others |

| Delivery Time | 1 Week |

| Sample Policy | Contact us for information regarding our sample policy |

| Main Export Market(s) | Asia |

| Main Domestic Market | All India |

Product Overview

Key Features

Item Details:-

Screening Area9 m cubic

Speed1800 to 3600 rpm

Stroke0.5 to 2.6mm

Screen Total Width1.8 mm

Screen Total Length5.0 m

Screen Total Height2.9 m

Engine Power2x3.8 (HP)

Number Of Decks6

BrandMetso

Demonstrate NumberUFS 6

Picking Metso as your provider for gear for your piece reusing process gives you the best execution generally and the Metso Lindemann EtaRip has some solid and dependable working standards.

The new Metso Ultrafine Screen is a high recurrence vibrating wet screen intended for applications requiring division from 0.075 to 1mm. It is a great option to hydrocyclones for low limit plants or for activities with heterogeneous materials. In hydrocyclones, feed metal parts with various strong densities will arrange at various cut sizes, which can be adverse in specific procedures. UltraFine Screens can likewise be utilized related to hydrocyclones in a two-arrange order circuit to get a mix circuit to get the best harmony among cost and productivity to most extreme the operational rate of return.

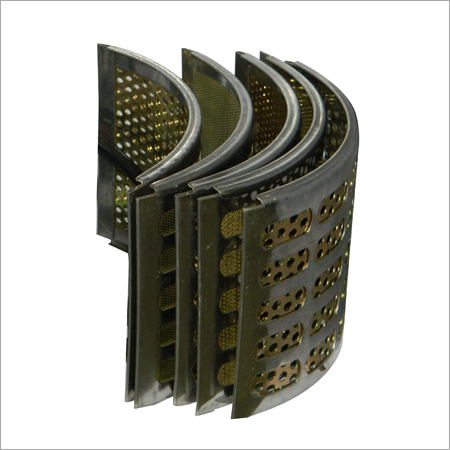

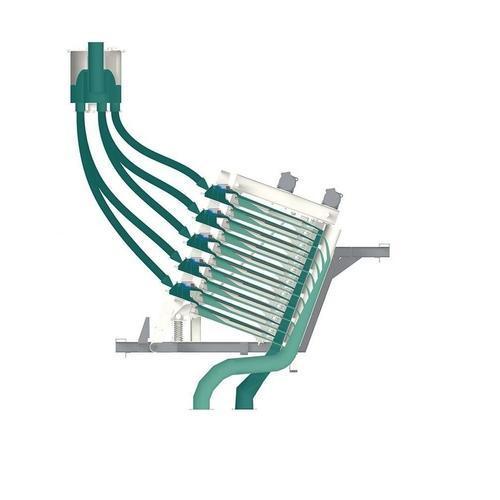

Contingent upon the design of the unit, the feed slurry reports to a splitter box and the subsequent sub-streams move through hoses to the screen feed gulfs - 1 for each 2 decks. Every one of these feed streams are additionally part into two streams to uniformly sustain over the whole width of every one of the screen decks. Each screen deck utilizes two side tensioned boards of polyurethane screening media material with the fitting gap size to accomplish the coveted division.

Mines Crushing and screening contractual workers Fine screen media is presently fabricated to a standard size, bringing about impediments in the screening unit limits. In higher limit applications, this outcomes in the requirement for various units and a substantial in general impression in respect to elective classifiers, for example, hydrocyclones. Also, the use of fine screening innovation commonly requires a higher capital consumption for a given feed limit.

The Metso UltraFine screening innovation fuses a few patent pending highlights to convey the most elevated amounts of execution, unwavering quality, and practicality in a minimal and financially savvy unit.

Creative feed merchants were joined into the UFS configuration to consider the minimal course of action of the settled screening decks. These two-way feed splitters give a component to both split an approaching stream between two screening decks and guarantee that the feed is uniformly circulated over the width of every individual deck.

Highlights

Metso's UltraFine Screen uses a particular outline with up to 10 singular screen decks settled together into a solitary vibrating get together. Exact feed dissemination over the 10 decks is basic, so the unit additionally incorperates a patent pending feed splitter box to guarantee the feed is equitably dispersed over the entire width of each screen deck.

This machine game plan conveys twofold the screening territory with respect to other fine screen advances in a substantially more minimal by and large gathering. The littler impression contributes lessened building and foundation cost and altogether significantly decreases the capital expense to actualize this innovation.

UltraFine screening takes into consideration coordinate arrangement by measure through the physical measurements of the screening media gap which is more productive than Hydrocyclones that characterize material in light of mass. Also, screening execution is less impacted by plant operational fluctuation and require littler pumps. These add to bring down working expense because of vitality productivity and enhanced recuperation.

Company Details

Business Type

Manufacturer, Service Provider, Supplier

Working Days

Monday To Sunday

GST NO

06AAACS3407L1ZG

Related Products

Seller Details

GST - 06AAACS3407L1ZG

Gurugram, Haryana

Mr. Manjeet

Address

1st Floor, DLF Building No. 10, Tower A, DLF Cybercity, DLF Phase II, Gurugram, Haryana, 122002, India

Report incorrect details