Machinery & Parts

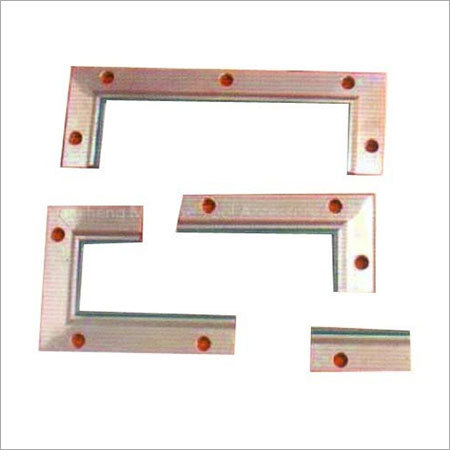

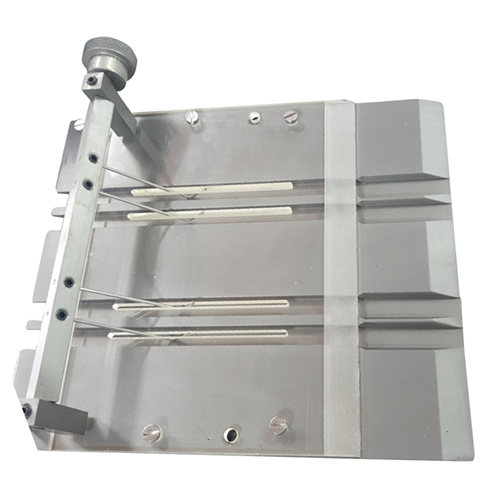

(12768 products)Way Wiper - Color: Sliver

Price: 500 INR/Piece

MOQ1 Piece/Pieces

Surface FinishPolished

Usage & ApplicationsIndustrial

Product TypeMachine Accessories

MaterialStainless Steel

Surface TreatmentCoated

ColorSliver

Scutes India Pvt. Ltd.

Pune

Trusted Seller

Trusted Seller8 Years

Super Seller

Super SellerSteel Rolling Mill Parts - Color: Silver

MOQ2 Ton/Tons

Product TypeMachine Spare Part

MaterialSteel

Surface TreatmentCoated

ColorSilver

Sanjay Casting & Engineering Company

Howrah

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller16 Years

Vibratory Bowl Feeder - High Quality Raw Material | Global Quality Standards Compliance, Durable Design, Precision Orientation

Product DescriptionWe are instrumental in providing excellent quality Vibratory Bowl Feeders which are highly appreciated by our clients, who are based all across the globe. While manufacturing these Vibratory Bowl Feeders we ensure to use high quality raw material, so the the feeders we deliver are in compliance with

Magna Tronix

Chennai

Trusted Seller

Trusted Seller4 Years

Super Seller

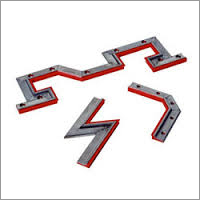

Super SellerBlack And Red Machine Way Wipers

Price Trend: 1000.00 - 10000.00 INR/Piece

MOQ1 Piece/Pieces

ColorBlack and Red

Product TypeMachine Way Wipers

UsageIndustrial

TypeMachine Way Wipers

MaterialSS, Rubber

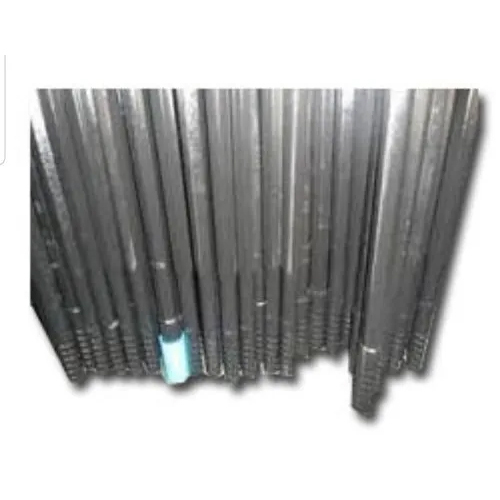

Twin Screw Barrel - Color: Grey

MOQ1 Unit/Units

Surface FinishPolished

Usage & ApplicationsIndustrial

MaterialMetal

Power SourceElectricity

Surface TreatmentCoated

ColorGrey

Precihole Machine Tools Pvt. Ltd.

Bhiwandi

Bulker Unloading System Blower - Color: Blue

Price: 200000 INR/Unit

MOQ1 Unit/Units

Usage & ApplicationsIndustrial

ColorBlue

Surface FinishPolished

MaterialSS

Surface TreatmentCoated

Warranty2 Year

Air Vac Equipment

Ahmedabad

Trusted Seller

Trusted Seller18 Years

Super Seller

Super SellerCopper Kiln Tyre

MOQ1 Plant/Plants

Product TypeMachine Accessories

MaterialSteel

ColorCopper

Ashoka Machine Tools Corporation

Greater Noida

Trusted Seller

Trusted Seller21 Years

Super Seller

Super SellerSpares And Manganese Casting

Product DescriptionWe are a well known name in the offering field of Spares And Manganese Casting. Our expertise lies in providing quality spares for construction equipment like Jaw Crusher Plates, Bowl, Concave, Side Plates, Toggle Plates, Toggle Bearings and Liners etc. Further, we can also offer Cast Iron Castings

Mechanical Impellers - Precision Machined for Superior Dimensional Accuracy, Enhanced Efficiency & Lightweight Design

Product DescriptionWe provide technically accurate array of mechanical impellers that are known for their dimensional accuracy and efficient performance. The impellers are precision machined and they have improved accuracy and efficiency. The impeller vane shapes are contoured for maximum performance and the exception

Esspee Engineers

Kolkata

Trusted Seller

Trusted Seller11 Years

Super Seller

Super SellerMetallic Grey Innovative Tablet Press Turret With Elp For Corrosive Resistance

Price: 95000 INR/Unit

ColorMetallic grey

Product TypeMachine Spare Part

MaterialSteel

Surface TreatmentCoated

Weight150-200 Kilograms (kg)

Mini Online Rotogravure Printing Cylinder - Color: Silver

Price: 4000 INR/Piece

MOQ100 Piece/Pieces

Surface FinishSmooth

Usage & ApplicationsRotogravure Printing Machine

Product TypeMachine Accessories

MaterialMild Steel

Surface TreatmentGalvanized

ColorSilver

Print Pack Stereo

Vadodara

Trusted Seller

Trusted Seller7 Years

Premium Seller

Premium SellerMotor For Band Sealer Machine - Power: 240 Volt (V)

Price: 4500.00 INR/Piece

MOQ1 Piece/Pieces

Product TypeMachine Parts

MaterialMotor For band sealer machine

TechnologyOther

Power240 Volt (v)

Warranty1

Cnc Precision Parts

Price: 1000 INR/Piece

MOQ10000 Piece/Pieces

Product DescriptionCnc Precision Parts

Labh Projects Pvt. Ltd.

Ahmedabad

Trusted Seller

Trusted Seller4 Years

Super Seller

Super SellerRoller Table - Heavy Structural Steel Frame with Guards & Stiffeners | Robust Design with Machined Pads & Heavy Duty Pipe Rolls

Product DescriptionOur organization hold expertise in providing excellent quality Roller Table to our valuable clients. Roller Table will be complete with guards, aprons and base frame of heavy structural steel fabricated with stiffeners and cross beams as ties. Robust and rigid construction base frame with machined

Mindman Parallel Gripper (MCHH)

MOQ40 Piece/Pieces

Payment TermsCash on Delivery (COD), Cash Against Delivery (CAD), Delivery Point (DP), Cash in Advance (CID), Cheque, Cash Advance (CA)

Sample AvailableYes

Sample PolicyContact us for information regarding our sample policy

Nano Technologies

Chennai

Trusted Seller

Trusted Seller6 Years

Super Seller

Super SellerLift Main Sheave

Product DescriptionWe are counted among the trustworthy and leading manufacturer and suppliers of an exclusive array of quality assured Lift Main Sheave in Ahmedabad, Gujarat, India to the customers. Made from the best quality basic material, offered products are available with us in different sizes. Moreover, these

Romaco Machine Feeding Channel - Color: Silver

Price: 475000 INR/Unit

MOQ1 Unit/Units

SizeStandard

Usage & ApplicationsIndustrial

MaterialMild Steel

Voltage220 Volt (v)

Surface TreatmentCoated

ColorSilver

Nikhil Pharma Packages Co.

Mumbai

Trusted Seller

Trusted Seller2 Years

Super Seller

Super SellerPin Joint Bus Bar

Price: 400 INR

Payment TermsCheque, Cash Advance (CA)

Supply AbilityAs per customer requirement Per Week

Delivery Timeone Week

Industrial Rewinding Line

MOQ1 , Unit/Units

Supply Ability1 Per Week

Delivery Time1 Days

Victory Plant And Machinery Private Limited

Thane

Trusted Seller

Trusted Seller5 Years

Super Seller

Super SellerDrag Chain - Plastic Material, CNC Machined, Black Color | Durable Round Design for Optimal Cable Protection

Price Trend: 900-25000 INR/Meter

MOQ1 Milliliter/Milliliters

Product TypeMachine Parts

Materialplastics drag chian

TechnologyCNC

ColorBlack

Backler India Private Limited

Bhosari

Trusted Seller

Trusted Seller6 Years

Super Seller

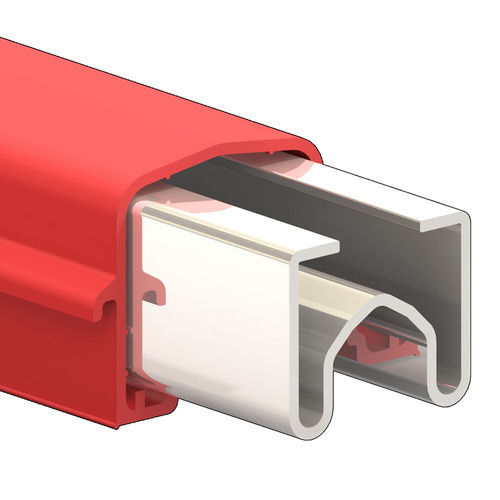

Super SellerCurrent Collectors - High Quality Raw Material | Hassle Free Performance in Material Handling Industries

Product DescriptionThese Current Collectors are made from very high quality raw material which ensures hassle free work performance at its user end. These Current Collectors are widely finds its applications in various material handling industries

Silverline Metal Engineering Pvt. Ltd.

Mumbai

Trusted Seller

Trusted Seller18 Years

Super Seller

Super SellerSilver Industrial Pharmaceutical Machine Parts

Price: 30000 INR/Set

MOQ1 Set/Sets

ColorSilver

Product TypeMachine Spare Part

MaterialSS

Surface TreatmentPolished, Other

Twin Sreew Barrel

Price: 150000 INR/Set

MOQ1 Set/Sets

Surface FinishPolished

Usage & ApplicationsIndustrial

Product TypeOther, Twin Sreew Barrel

MaterialMild Steel

Jimkhaas Extrusions

Ahmedabad

Trusted Seller

Trusted Seller2 Years

Premium Seller

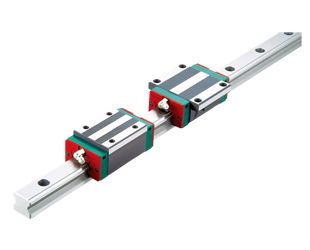

Premium SellerIndustrial Hiwin Qe Series Quiet Linear Guideway

Delivery Time1 Week

Sample PolicyContact us for information regarding our sample policy

Main Export Market(s)Middle East, Asia

Victor Enterprise

Mumbai

Trusted Seller

Trusted Seller13 Years

Super Premium

Super PremiumBlue Hydraulic Iron Worker Machine

Product TypeMachine Parts

MaterialStainbless Steel

ColorBlue

Weldor Engineering Pvt. Ltd.

Rajkot

Trusted Seller

Trusted Seller4 Years

Super Seller

Super SellerWhite 240 V Plan Sifter Bag

Price: 102 INR/Piece

MOQ50 Piece/Pieces

Product TypeMachine Parts

MaterialRubber

Voltage240 Volt (v)

Surface TreatmentCoated

ColorWhite

Partik Trading Company

Howrah

Premium Seller

Premium SellerO Ring Washer - Color: Multicolor

Usage & ApplicationsIndustriual

Product TypeMachine Parts

MaterialPlastic

Surface TreatmentPainted

ColorMulticolor

Shreeji Pharmatech

Ahmedabad

Trusted Seller

Trusted Seller7 Years

Super Seller

Super SellerLatest From Machinery & Parts

MS Machinery Parts

By:

Bajarang Fabricators

Rolling Mill Machinery Parts

By:

Alseena Group Industries

MACHINERY PARTS

By:

Infratech Spares

Investment Casting of Machinery Parts

By:

Prozen Technocast

Plastic Machinery Parts Heater For Mold Temperature Controller

By:

Guangdong Soxi Intelligent Equipment Co., Ltd.

Durable Plastic Machinery Parts

By:

Quality Steel Works

Explore More Cities

Ready To Ship Machinery & Parts

Machinery & Parts: Types And Applications

Introduction to Machinery & Parts

To apply forces and regulate motion, a machine requires a power source. Machines can refer to either man-made devices like those powered by engines or motors, or natural biological macromolecules like molecular machines.

A machine part is the smallest individual mechanical part or assembly of a machine in mechanical engineering. They serve a specific purpose and can't be substituted for anything else. Although a bearing can be disassembled into its component mechanical parts—balls, rings, and seals—these elements cannot carry out the bearing's job.

Many different kinds of machines rely on these components. Fasteners (screws, nuts, rivets, etc.), chains, shafts, keys, bearings, and belts are all instances of multipurpose machine elements. In most of these devices, they serve the same purpose.

What are the Various Parts of a Machine

1. Bearings

Bearings are a ubiquitous component of mechanical systems. Their duty is to reduce or eliminate sticking or rubbing between moving components. Without it, the mechanical design of rotating machines would be without a crucial component.

You can find them in a wide range of sizes and forms. The wide variety of bearing types on the market allows engineers to find the best one for each application, maximizing reliability, efficiency, performance, and durability.

Depending on the kind of bearing, they can transfer radial loads from the spinning part to the bearing housing or axial loads (thrust bearings).

2. Motor

It's the thing that does the work by changing the shape of the energy that powers it or burns it. The motors themselves are energy converters, converting kinetic, chemical, or electrical energy into mechanical power. This is doable with a rotating axis or a piston that moves in and out of the same hole at different speeds. Transformers are motors that can change mechanical energy into motion. This class also contains compressors and pumps.

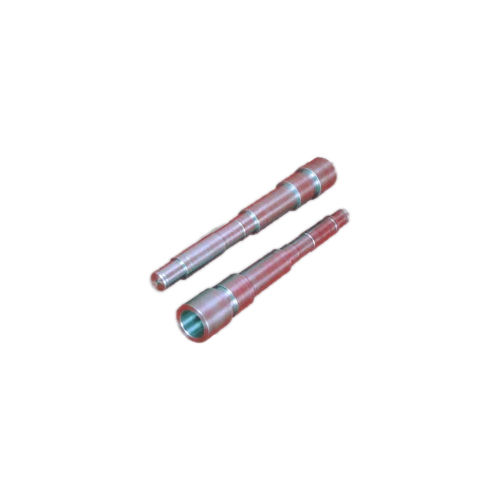

3. Shafts

Typically, shafts are CNC machined after being developed for a specific purpose. Shafts are long, cylinder-shaped parts that are used to transmit mechanical power and torque between two other parts.

Engineers utilize them when a direct connection would be impractical due to physical separation or when two or more parts of the drive train must function in different conditions.

From the engine room to the pump room, the bulkhead is only penetrated by the shaft. When in use, the steam turbines in the engine room generate a great deal of heat.

4. Keys

Keys are tiny mechanical pieces used in machine design to couple shafts to other moving parts. Torque between the two parts may be transferred only via them in some instances. The keyway is the term for the slotted opening in the hub. When the key is inserted into the shaft, it rests on the keyseat at the bottom of the keyway.

A keyed joint is the entire assembled unit. When keys are put in the axial direction, a keyed joint prevents any relative rotational motion but may permit some axial motion.

5. Frame

The engine and the system are held in place by a sturdy frame. To ensure the connection or coupling of all machine parts is its job. The safety of the product depends on numerous factors that must be considered during the frame's design phase. The best possible structure can then be designed based on the analysis of effort and deformation performed on each machine part.

6. Couplings

Couplings, in the context of mechanical design, are components that join two rotating in-line shafts for the purpose of transmitting power. Each component in the assembly spins at the same rate. Depending on the situation, a connection might be either rigid or flexible.

Flexible coupling can compensate for little misalignments in the shafts that may occur during installation or over time. In addition to protecting machinery from damage, they extend its useful life by dampening vibration and shock.

7. Regulation and Control System

These are the parts of the machine that allow the operator to adjust the power output in order to match the workload. Indicators, buttons, switches, actuators, and controls all fall under this category.

8. Fasteners

When designing machines, it's crucial to have as much detail as possible when it comes to the design or selection of fasteners. This is done to guarantee that the machine parts in question are up to the task of withstanding the loads imposed by the product while in use. Standard fastener materials include carbon steel, stainless steel, and alloy steel.

9. Gears

Wheels with teeth are used in gears, which are one of the simplest types of machine parts. Gears transmit rotational energy from one shaft to another. In accordance with the principles of energy conservation, they are able to either raise or reduce angular velocity while doing the opposite to the torque. These components serve essentially as levers in a mechanical system that facilitates translation.

Different Types of Machinery & Parts and Their Applications

1. Drill Press

A drill press is a type of machine tool typically employed in the metalworking industry for the purpose of drilling. A work surface, known as the bed, is typically included to enable the component being drilled to be held in a vertical position, and it can be operated manually or electrically.

They are more stable than traditional hand drills and may be used with confidence. Making drills at the workbench is a continuous process that guarantees pinpoint accuracy. Drill presses have been used in the metalworking industry for hundreds of years.

2. Hobbing Machines

When it comes to the metalworking industry, hobbing machines have been instrumental in boosting both quality and productivity. They are a sort of milling machine that uses a unique cutting tool to manufacture precise cylindrical components such as shafts, gears, splines, and many more. At the very least, any metal factory worth its salt will have a couple of hobber machines. They can produce vast volumes of parts per day for a low cost and with a small staff.

3. Shearing Machine

Shearing machines are used to cut sheet metal to certain dimensions. The lack of chips and other residue from the shearing process makes this metalworking equipment particularly well-suited to use in factories, where such waste would otherwise litter the workplace. Shearing machines, like the other tools on this list, are indispensable in the majority of metal fabrication factories. Shearing is related to blanking and piercing, two additional major metal-cutting procedures.

4. Planer Machine

Parallels can be drawn between shaper machines and planar machines. In truth, this device is identical to others like it, with the exception that the cutting tool remains in one place while the workpiece is moved in a straight path. Additionally, these tools are often bigger than shaper machines. Metals like steel can have their thickness and dimensions modified by using these tools during the machining process. In addition, it can be used to smooth out uneven surfaces.

5. Broaching Machines

Materials of all kinds can be cut, shaped, and formed by a broaching machine. A broach or toothed tool is used to cut away excess material. Broaching can be done either in a linear or circular fashion. Linear broaching, in which the machine is parallel to the workpiece, is the more prevalent method. But in rotary broaching, the broach is spun while being used on the workpiece. Broaches are multipurpose instruments that can be put to work in a wide range of settings. They make a wide variety of items for use in metalworking, which are sold to professionals in the field.

6. Shaper Machine

In order to shape a workpiece, a shaper machine employs a single-point cutting tool that travels in a linear motion. The operation is straightforward and the device is intuitive to use. Metal can be cut, shaped, or formed with these mills. Because of the way they are usually set up, they may easily reach the material from any angle.

7. Drilling Machine

One of the most ubiquitous machine types in a metalworking workplace is the drilling machine. They are also handy for a wide range of home maintenance tasks. Drilling machines are user-friendly because their tools are simple to install and swap out.

8. Grinding Machine

A grinding machine utilizes the rotation of an abrasive wheel to achieve the desired finish. The workpiece is finished by the rotating wheel, which removes a very fine layer of material along the surface, leaving it feeling smooth to the touch. After other instruments like saws or lathes have been used, a grinder can be used to refine the shape, flatten, and smooth the surface of the cut parts. In order to refinish or refurbish an item, abrasive materials can be used to get rid of any rust or old paint.

9. Milling Machine

Using rotary cutters, the milling machine is a metalworking tool. A vertically moveable work table secures the workpiece while a rotating tool can be moved around it. In general, a milling machine can conduct two distinct types of milling: face milling and peripheral milling. Unlike peripheral milling, in which the cutter is set perpendicular to the workpiece, face milling involves cutting a flat surface at right angles to the rotation of the cutter.

Conclusion

Although each part of the machine functions autonomously, they all contribute to the machine's overall ability to affect motion. This summary of machine automation parts is meant to be informative and comprehensive. Experts can answer any queries you may have about machine parts and automation design, as they are a leading industrial parts supplier and bespoke automation specialist.

FAQs: Machinery & Parts

Q.How do you identify machine parts?

Ans. To check the quality of machine parts, don’t forget to check the warranty. Meet manufacturers and collect the ideal detail about the machine you’re purchasing for the specific task.

Q.What materials are used to manufacture machinery & parts?

Ans. The material includes Aluminium, Zinc, Stainless Steel, Copper, Magnesium, Titanium, Bronze, Brass, and Iron.

Q. What are some examples of general and special-purpose machinery & parts?

Ans. Developed to meet the specific needs of a given industry, Special Purpose Machines are highly sophisticated pieces of machinery that are fully automated and programmed. These mechanical components have a designated place in the creation of machines.

Q.How much does it cost to replace machinery & parts?

Ans. Producing machinery rarely fetches what it would cost to replace it at the market value of 500–10,000 INR.

Manufacturers & Suppliers of Machinery & Parts

Company Name | Member Since |

|---|---|

Ugi Engineering Works Pvt. Limited Kolkata, India | 23 Years |

Ashoka Machine Tools Corporation Greater Noida, India | 21 Years |

Air Vac Equipment Ahmedabad, India | 18 Years |

Silverline Metal Engineering Pvt. Ltd. Mumbai, India | 18 Years |

Sanjay Casting & Engineering Company Howrah, India | 16 Years |

Moderate Machines (Pvt.) Ltd. Jaipur, India | 14 Years |

Victor Enterprise Mumbai, India | 13 Years |

Esspee Engineers Kolkata, India | 11 Years |

Shypod Engineers Ahmedabad, India | 11 Years |

Gurukrupa Bellows Pvt Ltd Pune, India | 10 Years |

Popular Products