Filter Cloth, Filter Industrial

(4950 products)Pleated Filter Bag Application: Dust Control

Price Trend: 5000.00 - 10000.00 INR/Piece

MOQ5 Piece/Pieces

SizeAs per customer requirement

Efficiency (%)99.9%

UsageFor Pollution control

ColorBlack, white and Yellow

Product TypePleated Dilter

Weight2-5 Kilograms (kg)

R+b Filter Manufacturing Enterprises Pvt. Ltd.

Vadodara

15 Years

Super Premium

Super PremiumBag Filter - Application: Industrial

Price: 200 INR/Piece

MOQ10 Piece/Pieces,

ColorWhite

UsageWater Purification

Product TypeBag Filter

SizeSizes Available

MaterialPP

ApplicationIndustrial

Angel Chemicals Private Limited

Vadodara

11 Years

Super Premium

Super PremiumTrickling Filter And SAFF Media

MOQ100 Cubic Meter/Cubic Meters

FOB PortMumbai

Payment TermsLetter of Credit (L/C), Cheque

Delivery Time1 Months

Cooldeck Industries Pvt. Ltd.

Mumbai

7 Years

Super Premium

Super PremiumPulse Jet Bag Filter - Material: Metal

Price: 400000 INR/Piece

MOQ1 Piece/Pieces

UsageIndustrial

SizeDifferent Available

Product TypePulse Jet Bag Filter

MaterialMetal

ApplicationIndustrial Filter

Parth Engineers

Ahmedabad

3 Years

Super Premium

Super PremiumGray Industrial Dual Media Filter

Price: 80000 INR/Unit

MOQ1 Unit/Units

Product TypeDual Media Filter

ColorGray

MaterialStainless Steel

ApplicationIndustrial, Chemical Industry, Domestic Industry

Inhibeo Water Solution & Technologies Pvt. Ltd.

Indore

5 Years

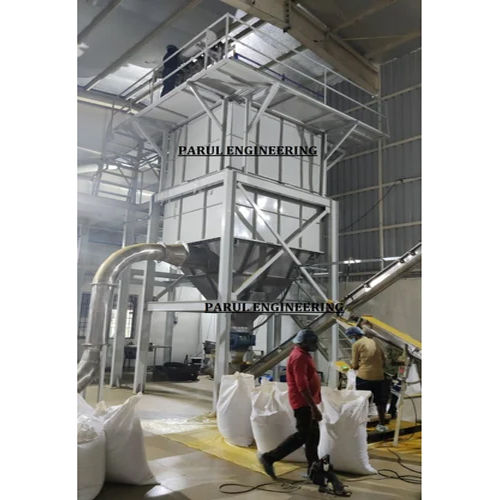

Bag Filter System - Other Material, Grey Color | Food Industry Usage

Price: 200000 INR/Piece

MOQ1 Piece/Pieces

Product TypeBag Filter System

ColorGrey

UsageFood Industry

MaterialOther

Parul Engineering Private Limited

Pune

3 Years

Super Premium

Super PremiumLow Density Filter Media - 100% Polyester, Breaded Density | High Strength, Dimensional Accuracy, Durable Finish Standards, White Color, Ideal for Clean Room Filtration

Price Trend: 1000.00 - 10000.00 INR/Unit

MOQ1 Unit/Units

ColorWhite

Product TypeSuction Air Filter Media

UsageIndustrial

Tfi Filtration (india) Pvt. Ltd.

Ahmedabad

17 Years

Electroplating Chemical Filter

Price: 22000 INR/Piece

MOQ1 Piece/Pieces

Payment TermsTelegraphic Transfer (T/T), Others, Cheque

Sample AvailableYes

Sample PolicyContact us for information regarding our sample policy

Fine Rhodium

Mumbai

16 Years

Combination Grilles With Filter Frame - Superior Quality Materials , Enhanced Performance Design

Product DescriptionWe bring forth for our clients superior quality Combination Grilles With Filter Frame. While manufacturing these Combination Grilles With Filter Frame, we take extra care of quality so our clients get best product. Our clients can avail from us these products at most competitive rates.\015\012

Revlon Industries

Ahmedabad

16 Years

Super Premium

Super PremiumFoam Filter - Premium Quality Material, Cutting Edge Technology - Manufactured by Skilled Professionals

Payment TermsPaypal, Western Union, Telegraphic Transfer (T/T), Others

Delivery Time1 Week

Sample PolicyContact us for information regarding our sample policy

Shraddha Filter Technology

Ahmedabad

6 Years

Industrial Liquid Filter - Premium Stainless Steel, Efficient Multi-Layer Filtration for Optimal Performance

Price Trend: 15000.00 - 50000.00 INR/Piece

MOQ1 Piece/Pieces

Supply Ability50 Per Month

Delivery Time1 Week

Gts Filters And Systems (india) Private Limited

Vadodara

7 Years

Reverse Pulsejet Bag Filter System - Color: As Per Customer

Price: 45000 INR/Unit

MOQ1 Unit/Units

ColorAS PER CUSTOMER

Power SourceElectricity

Warranty1 YEAR

United Air Tech Industries

Mumbai

17 Years

Carbon Filter For Etp - Application: Industrial

Price: 100000 INR/Unit

MOQ1 Unit/Units

ColorGrey

Product TypeCarbon Filter For ETP

MaterialStainless Steel

ApplicationIndustrial

Sunrise Process Equipments Private Limited

Mumbai

22 Years

Titled Plate Interceptor - Application: For Effluent Waste Water

Price: 425000 INR/Piece

MOQ1 Piece/Pieces

Product TypeTitled Plate Interceptor (TPI)

UsageWater treatment for First Stage

ColorBiue

ApplicationFor Effluent Waste Water

K-pack Systems Private Limited

Bengaluru

15 Years

AIRLINE FILTERS

Product DescriptionThe Airline Filter is designed to remove oil mist, water vapor and particulates down to 0.5 microns from breathing grade compressed air. Once the air has been filtered, moisture is removed and drained through a drain valve located at the bottom of the airline filter

Atlantic Maritime Services Pvt. Ltd.

Mumbai

8 Years

Grp Auto Self Cleaning Filters - Material: Stainless Steel

Price: 200000 INR/Unit

MOQ1 Unit/Units

UsageIndustrial

Product TypeSelf Cleaning Filters

SizeStandard

MaterialStainless Steel

Shalin Composites (india) Private Limited

Palghar

5 Years

Super Premium

Super PremiumPulse Jet Bag Filter - Stainless Steel, Standard Size, Blue Color | Industrial Application, Durable Design

Price: 450000 INR/Piece

MOQ1 Piece/Pieces

ColorBlue

Product TypePulse Jet Bag Filter

SizeStandard

UsageIndustrial

MaterialStainless Steel

ApplicationIndustrial

Ambica Boiler

Ahmedabad

9 Years

Dual Flow Bag Filters

Price: 360.00 INR/Unit

MOQ10 Unit/Units

Supply Ability5000 Per Month

Delivery Time30 Days

Trinity Filtration Technologies Pvt. Ltd.

Thane

13 Years

Automatic Filter - Fully Automatic Design, Self-Cleaning Mechanism, Yellow Finish, Low Maintenance Costs, High Flow Rate Up to 8000 m3/h, No Lubrication Required

Price Trend: 80000.00 - 350000.00 INR/Piece

MOQ1 , Piece/Pieces

Product TypeAutomatic Filters, Other

TypeMachine Oil Filter

AutomationAutomatic

ColorYellow

WarrantyYes

Shalin Composites (india) Private Limited

Vasai

15 Years

Pvc Coated Fiberglass Cloth With Fire Retardant - Application: For Industrial

Price: 350 INR/Square Meter

MOQ1 Square Meter/Square Meters

TypeFilter Felt

MaterialPolypropylene

ApplicationFor Industrial

Hemnil Protection

Mumbai

13 Years

Non Woven Filter Bags Application: Edible Oil Filtration In Major Stages In Refineries

Size4 x 20 Inch

Product TypeNon Woven Filter Bags

TypeNon-Woven Filter

MaterialNon Woven, Other

ApplicationEdible Oil Filtration in Major stages in Refineries, Particle filtration for Paint Solid, and Liquid Filtration

Andisc Engineers Private Limited

Kolkata

15 Years

Hvac Pre Filter - Shape: Square

Price Trend: 1000.00 - 10000.00 INR/Piece

MOQ10 Piece/Pieces

Product TypeHVAC PRE Filter

UsageIndustrial

ConditionNew

ShapeSquare

United Filters Industries Pvt Ltd.

Pune

11 Years

Bag Filters - Special Fiber Fabric, Versatile Sizes for Various Processes | Enhanced Dust Removal, Durable Design, Easy Maintenance Features

Product DescriptionWe are involved in offering fine quality Bag Filters which are large fabric bags, usually made of special fibers, used to eliminate intermediate and large particles greater than 20 microns in diameter). It operates like the bag of an electric vacuum cleaner entrapping the solid particles on the surf

Microtech Boilers Private Limited

Ahmedabad

9 Years

Integrative Pool Filter System

Payment TermsDelivery Point (DP), Days after Acceptance (DA), Cheque

Sample AvailableYes

Sample PolicyContact us for information regarding our sample policy

D S Water Technology

Delhi

12 Years

High Grade Inline Filters

Payment TermsCash on Delivery (COD), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cash in Advance (CID), Cheque

Delivery Time3-4 Week

Sample AvailableYes

Excel Filtration Pvt. Ltd.

Ahmedabad

9 Years

Filter Bag - Customized Sizes for Air, Gas, and Liquid Filtration | Ideal for Dairy, Pharmaceutical, Food, Chemical, and Textile Industries

Product DescriptionWe are the leading manufacturer of industrial Filter Bags in standard as well as customized sizes. These bags are used for air, gas and liquid filtration in various industries like dairy, pharmaceutical, Food & Water, Chemical, Cosmetic, Medicine, Textile, etc.. Clients can avail this Filter Bag at

Sheetal Enterprises

Ahmedabad

10 Years

Filter Bag - Size: Different Available

Price: 300 INR/Unit

MOQ100 Piece/Pieces

SizeDifferent available

Product TypeFilter Bag

UsageIndustrial

Equipment TypeFilter Bag

ConditionNew

WarrantyYes

Rohan Engineering Enterprise

Howrah

18 Years

Latest From Filter Cloth, Filter Industrial

Milling Filters

By:

Shreeji Screen & Filters Pvt. Ltd.

Explore More Cities

Ready To Ship Filter Cloth, Filter Industrial

What are Filter Cloth & Industrial Filters?

Introduction

Filter clothes used in the industrial sector are woven from a variety of filter materials using intricate weaving techniques.

Materials are selected with consideration for the surrounding chemical and thermal conditions. Filtration quality, mechanical resistance, and anti-adhesion properties in the filter cake discharge were all taken into account when deciding on the weave type.

Monofil, mutifil, and staple fiber yarns are only a few of the many varieties available. You may also create a complex weave by combining different kinds of yarn.

Particles in the air and other gases are filtered out in factories using specialized equipment. Air filtration and separation systems are essential in many industrial operations for the sake of worker safety and the preservation of expensive machinery.

Benefits of Filter Cloth & Industrial Filters

Numerous sectors rely on filtration equipment for various purposes. The filter cloth has many uses, including purifying water, minimizing airborne dust emissions, filtering food, and even distilling blood plasma. Companies that make and sell filtration supplies including filter clothes filter cages, and filter bags help other businesses that rely on effective filtration to function normally. Here are the benefits of filter cloth and Industrial filters:

-The use of gravity and low head loss in filtration

-Filtration occurring in real-time without the need for periodic back washing or pauses

-Filter cloth made of synthetic fibers that have been treated to provide great mechanical strength and freedom from harmful chemicals

-Discharge TSS values less than 5 mg/l indicate a highly efficient filtration system.

-Very low-power consumption cloth backwash

-Elimination of Air and Noise Pollution

-Capability of adjusting to changing input conditions and a degree of resilience to overload

-Dimensional Minimalism

-Small amounts of water used for backwashing

-Excellent efficiency in dust capture, both coarse and fine;

-Both pressure drop and effectiveness are insensitive to changes in load;

-In some cases, the dust collected can be recycled for use in the procedure;

-Concentrations entering the system are what ultimately influence residual emissions;

-Very simple in operation

-Monobloc and concrete tank versions are both user-friendly.

-Infrequent upkeep

-The convenience of having immediate access to all services

-Impact on the environment is minimal.

Material Used in Filter Cloth & Industrial Filters

Nylon, polyester, polypropylene, and even more complex and pricey materials like PPS, E-CTFE, PEEK, and PTFE can all be found among synthetic filter textiles.

Many different kinds of fabrics can be used to make filter clothes. Even though some uses still exist for natural fibers, synthetic materials are typically employed to make filter cloth today.

All of the various synthetic materials have a price, which might range from 1 to 100. Therefore, it is crucial to aim the filtration rating and all of the ancillary factors such as pressure, PH, flow rate, mechanical resistance, temperature, budget, etc. as precisely as possible for each application.

Steel and stainless steel are still utilized, but only for highly specific molding uses or massive screen filtering. Stainless steel Filter Cloth, Filter Industrial is not always mechanically better than synthetic clothes, contrary to common opinion. This depends on the filtration rating.

1. Nylon Filter Cloth

Nylon filter cloth is well-praised for its effectiveness against adhesion and moisture retention in both extreme conditions and everyday use.

2. Polypropylene Filter Cloth

It's no secret that polypropylene cloth is the go-to material for filtering in the industrial sector. The corrosion resistance of this material is legendary.

3. Polyester Filter Cloth

The polyester fibers in filter cloth are what give it its great resistance to acids and mechanical strength. Useful for making filter press clothes, filter belts, or filter bags

4. Filter Cloth made of PEEK, PVDF, and PTFE

Users frequently express their appreciation for fluoropolymer filter clothes like PVDF and PTFE, yet these materials are infrequently employed. The high cost of raw materials and the complexity of the production process are the primary reasons behind this. PTFE or PEEK Teflon-type fibers are still only used in high-stakes situations due to their exceptional chemical resistance, thermal tolerance, and very good cleaning capabilities.

5. Cotton Filter Cloth

Filter cages of this sort have several applications in the manufacturing sector. Filter cages made of cotton are extremely common. Sheets for hotels, tarps, tents, and military outfits are just some of the many products that benefit from this versatile fabric. Bandages, gauze, and cotton wool are all common medical devices that rely on them to staunch bleeding.

6. Vinylon Filter Cloth

Polyvinyl alcohol is the chemical term for the vinylon filter cloth. Its wear resistance is better and its longevity is 1-2 times that of pure cotton, but its strength is lower than that of polyester, its elasticity is weak, and the fabric does not retain its shape well.

It's impervious to the effects of alkalis and absorbs and releases moisture effectively. It combines well with rubber and is simple to do so. The rubber sector would benefit from this substance.

Types of Filter Cloth & Industrial Filters

Yarn-Based Filter Cloth Types:

1. Spun Yarn

Staple (spun) yarn is made by twisting together multiple strands of short natural or synthetic fiber. This thread has the properties of good particle holding and high sealing performance when woven into filter fabric.

2. Multifilament Yarn

Two or more monofilament yarns are spliced together to create a multifilament yarn. High tensile strength, good cake release, and particle retention are some of the features of filter cloth produced from this yarn.

3. Monofilament Yarn

Synthetic monofilament yarn consists of a single, unbroken filament. Woven from monofilament yarn, the filter cloth has the qualities of being resistant to blocking, allowing for smooth cake release and effective particle retention.

Weave-based Filter Cloth & Industrial Filter Types:

1. Satin Weave

There are more than 5 parallel warp and weft threads in a satin weave. This type of weave is characterized by its discontinuous weaving points. Many of the warp or weft threads are free to float on the fabric's surface, making it an excellent dust barrier.

Satin weave has fewer weaving points than plain and twill, allowing for better air permeability, but more yarns float freely on the fabric's surface, making it more vulnerable to damage.

2. Twill Weave

The twill construction consists of more than three parallel warp and weft strands. On the fabric, we can see slanted lines. Filter bags are often made of twill. Points in twill weaving are fewer than in straight weaving.

The filter cake release efficiency will be greater than that of plain lines due to the greater porosity and improved permeability.

3. Plain Weave

When it comes to fabric weaves, the most frequent and affordable option is plain weave. With just two warp and two weft threads, you may create a whole plain weave cycle.

Despite the relative stability, there are a lot of simple weave spots that have little porosity. Plain weave filter fabric has a low filtration rate because of its low permeability.

FAQs: Filter Cloth & Industrial Filters

Q. What are the applications of filter cloth & industrial filters?

Ans. These are some common applications for filter cloth & Industrial filters;

a- Ceramics

b- Food Industries

c- Dust Collectors

d- Geotextiles

e- Vehicles

f- Chemicals

g- Board Mills

h- Shopping bags

i- Water filters

j- Pharmaceuticals

k- Paper industries and more

Q. What is filter cloth fabric usually made of?

Ans. The Filter cloth fabric is made from Nylon, Polypropylene, Polyester, Cotton, Polyamide, and Polyethylene along with highly advanced techniques.

Q. How do I choose a filter cloth & industrial filters?

Ans. Here is the guide:

a- It's important to use the right filter fabric for the level of acidity or alkalinity in your solution.

b- When it comes to filtering press efficiency, temperature is a crucial influence. The polyester filter cloth can withstand the highest heat levels.

c- The filtrate will readily leach out of the filter cloth due to the smooth and nonsticky surface of the filter cake. Filter cloth options include single silk and satin.

d- Whether or not the particles are consistent in size and shape can affect the filter cloth's wear resistance.

Q. How much does a filter cloth & industrial filters cost?

Ans. The cost of filter cloth & Industrial filters would be between Rs 100- 4,000 meters in India.

Manufacturers & Suppliers of Filter Cloth, Filter Industrial

Company Name | Member Since |

|---|---|

Sunrise Process Equipments Private Limited Mumbai, India | 22 Years |

Rohan Engineering Enterprise Howrah, India | 18 Years |

Tfi Filtration (India) Pvt. Ltd. Ahmedabad, India | 17 Years |

United Air Tech Industries Mumbai, India | 17 Years |

Blastech Mumbai, India | 17 Years |

Fine Rhodium Mumbai, India | 16 Years |

Revlon Industries Ahmedabad, India | 16 Years |

R+B Filter Manufacturing Enterprises Pvt. Ltd. Vadodara, India | 15 Years |

K-Pack Systems Private Limited Bengaluru, India | 15 Years |

Shalin Composites (India) Private Limited Vasai, India | 15 Years |

Popular Products