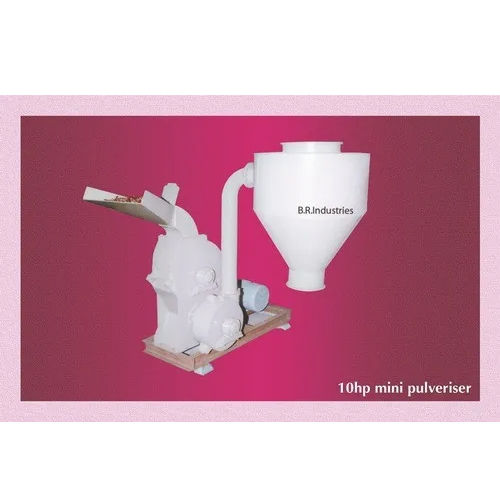

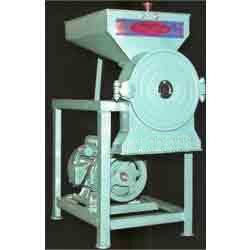

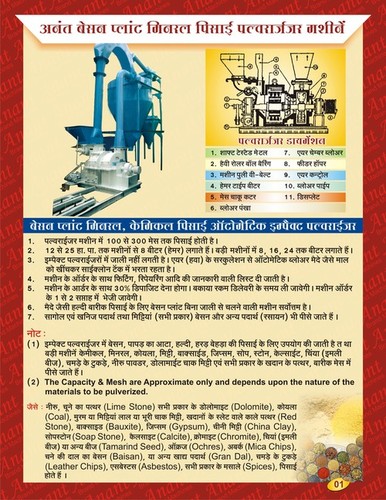

Pilot Mini PulveriserWe are specialized in manufacturing and exporting a premium quality gamut of Pilot Mini Pulveriser which is appropriate to grind sticky materials. These machines are highly suitable for flour mills, ayurvedic medicine manufactures, bakeries and chemical pulverising industries. Made using latest manufacturing techniques and quality raw materials procured from dependable sources of the industry, these Pilot Mini Pulverisers are known for features like sturdy design, compact size, high efficiency, low energy consumption and optimum performance. Construction and working: The material to be ground are fed into the chamber (crushing chamber) from a hopper. The beaters inside the chamber accelerate the material at a very high speed to the toothed liner placed at the upper half of the inner periphery of the chamber. The material is pulverised by impact and shearing. The ground material is discharged through the mesh placed at the lower half of inner periphery of the chamber. Excess air is filtered through a cotton balloon. The mesh can be varied as per the mesh size of the flour required. Main body & frame is made of high quality cast iron/M.S. channel frame, liner of high grade steel casting and bearings are lubricated oil (company supplying the machine without oil) Instead of rubber oil seals metal seals are used for avoiding friction & maintenance, which will occur due to the use of rubber seals. Also supply Pulveriser with Stainless Steel contact parts at the cost of 300% of standard Mini Pulveriser. Also add (S.S) along with model no. for S.S Pulveriser. For example Stainless Steel Pulveriser Model No. 410 is to be mentioned as Model No. 410(S.S). Standard Accessories supplied along with the machine- Sieves 4 nos. cotton balloon 1 No., & S.S air filter with nylon. Model Power (hp) Output Cap. Kg/Hr Wet rice Wheat Coriander Pilot408(portable) 2 30 12 6 Pilot 408 5 125 30 10 Pilot 410 7.5 200 50 20 Pilot 412 10 300 70 35 Pilot 815 15 500 110 50 Note: In the model number the first digit is the width of the drum and the last two digit is the dia of the drum in inches. For cutting wheat and rice into pieces reduce the normal recommended RPM to 650 and use suitable sieves which shown in the accessories. Rotating parts are well balanced, only sound is due to air blow, it can be reduced by reducing the RPM to 20 % which will slightly affect the output capacity.