Mobile Concrete Batching Plant - 12 To 25 Mâ³/hr Capacity | Fully Automatic, Electronic Load Cell Weighing System, Compact Design, Easy Transportation

Price:

Get Latest Price

In Stock

Product Overview

Key Features

Concrete Batching / Mixing Plant is a very innovative product of

PNEUCON Machinery; the plant can produce wet concrete with capacity of

120 m3/hr. capacity.

It is a fully

automatic Plant with electronic load cell type weighing batching system

for aggregates, cement, water & additive. The plant having

electronic weigh batching system with PLC based microprocessor control

for aggregate, cement, water & additive separately indicating Time,

Date, Batch Number, Weight etc for each cycle.

The Plant is equipped with 6 load cells for aggregate weighing, 3 load

cells for cement weighing, 1 load cell for water weighing and 1 load

cell for additive weighing. The recipes selection is to be entered and

as per the number of batches to be selected, all the operations are

carried out fully automatically. Salient Features

Concrete Batching/Mixing Plant available in 120 m3/hour capacity.

Rigid construction of main structure; fabricated from rolled mild steel material.

Aggregate stored by Inline Bins.

Replaceable Tiles and Tips in the mixer.

Independent

weighing system for Aggregate, cement, water & additive, reduces

the cycle time as the weighing is done simultaneously.

Aggregate weigh is suspended on four S type load cells, gives higher accuracy.

Ample space on platform with protective railing for easy maintenance.

Fully Automatic-Electronic operation with PLC/PC Control.

Maximum weighing accuracy.

Plant Available with Single Shaft, Twin Shaft, and Planetary and Pan Type mixer.

Technical Specification

Description

Units

BIN-45

BIN-60

BIN-80

BIN-120

Concrete Output/hr

m3/hr

45

60

80

120

Type of Mixer

-

Twin Shaft

Twin Shaft

Twin Shaft

Twin Shaft

Input/Output Capacity

Liter

1500/1000

2250/1500

3000/2000

4500/3000

*Output Batch

m3

1

1.5

2

3

Mixer Motor Power

HP

30 x 2 = 60

40 x 2 = 80

50 x 2 = 100

75 x 2 = 150

No. of Aggregate Bin

Nos.

4

4

4

4

Capacity of Each Bins

m3

15

25

30

30

Aggregate waiting hopper on mixer

-

Yes

Yes

Yes

Yes

Elevating Conveyor for Aggregate Dish.

-

Yes

Yes

Yes

Yes

Weighing System

-

Electronic Digital

Electronic Digital

Electronic Digital

Electronic Digital

Aggregate Scale

Kg

2500

3750

5000

7500

Water Scale

Liter

300

450

600

950

Cement Scale

Kg

600

900

1200

1800

Additive Scale

Liter

100

100

100

150

Water Connection

Diameter

2

2

2

2

Greasing System

-

Automatic

Automatic

Automatic

Automatic

Air Compressor

HP

5

7.5

10

12

Screw Conveyor

N.B.

8

8

10

10

Standard Supply of Screw

Nos.

1

1

1

1

Moisture Probe

-

Original

Original

Original

Original

Total Power

HP

126.25

158.25

179.25

248.75

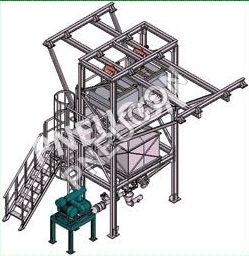

SECTION CONCRETE BATCHING / MIXING PLANT PSCP SERIES

Section - PSCP Series

concrete batching/mixing plant is very unique design to produce wet

concrete. The construction of plant is very rigid and the main sections

are fabricated in Section shapes for quick and easy install/dismantle

of plant.

The SECTION series of are

versatile and efficient plants. They are used for attaining correct and

homogeneous design mix of large amount of high grade concrete. They are

widely used for construction of Canals, Bridges, Highways, Dams,

Multi-storeyed & Industrial Buildings, Factories, and for Ready

Mixed Concrete works. The Concrete from Plant is discharged into

Transit Mixer, Concrete Pump, Dumper, Crane Bucket or Belt Conveyors.

Salient Features

Sectional Type designed fabricated sections used for sturdy construction.

Offered in 20, 30, 45m3/hr. capacity.

Single Shaft Compulsory Mixer, with two zone counter flow missing system to achieve homogeneous & speedy mix.

Independent weighing system for Aggregate, cement, water & additive, reduces the cycle time as it is weighed simultaneously.

Sturdy skip hoist track.

Fully Automatic-Electronic operation with PLC / PC Control.

Replaceable Hard-Liner tiles into the mixer.

Integrated Glass Cabin, to inspection of all operations.

Ample space on platform with protective railing for easy maintenance.

Easy to erect & dismantle due to bolted type design.

Simple & economical foundation.

Maximum weighing accuracy.

Also available with PAN type Mixer, Star Bins and Radial Dragline Scrapper.

Technical Specification

Description

Units

MODEL

PSCP-20

PSCP-30

PSCP-45

Concrete Output/hr

m3/hr

20

30

45

Type of Mixer

-

Single Shaft

Single Shaft

Single Shaft

Capacity of Mixer

Liter

250

500

750

Aggregate Storage

-

Star Batcher

Star Batcher

Star Batcher

No. of Compartment

No

04

04

04

Active Storage Capacity

m3

07

10

20

Boom Length

Meter

10

12

12

Stock Piles

m3

300

500

700

Aggregate Load Cells

No

04

04

04

Cement Load Cells

No

03

03

03

Water Load Cells

No

01

01

01

Skip Capacity

kg

1000

1500

2000

Cement Capacity

kg

200

300

600

Water Capacity

Ltr

100

150

200

Cement Screw Conveyor

NB

6

8

8

Vibratory Motor

-

Sand / Cement

Sand / Cement

Sand / Cement

Controls

-

Fully Automatic

Fully Automatic

Fully Automatic

Connected Power

kw

50.5

70

91.5

Concrete Discharge Height (With raised foundation)

Meter

4.2

4.2

4.2

Total Weight

MT

13

16

20

READY MIX CONCRETE - PRMC SERIES

This

is a fully automatic plant with electronic load cell type Weigh

Batching system for aggregates, cement and water. The plant having

electronic weigh batching system with PLC based microprocessor control

for aggregate, cement, water & additive separately indicating Time,

Date, Batch Number, Weight etc for each cycle.

The Plant equipped with 4 load cells for aggregate weighing, 3 load

cells for cement weighing, 1 load cell for water weighing and 1 load

cell for additive weighing. The recipes selection is to be entered and

based on the number of batches selected, all the operations are carried

out automatically i.e. if the plant is set on AUTO mode then

aggregate weighing, Bucket movement, cement weighing, water weighing

and discharge from mixer are all carried out according to the sequence

and for the number of batches selected.

Salient Features

Sturdy fabricated skip hoist track.

Heavy duty PAN type mixer for continuous mixing.

Mixer discharge done by powerful hydraulic cylinder.

Replaceable Tiles and Tips in the mixer.

Independent weighing system for cement, water & additive, reduces the cycle time as it is weighed simultaneously.

Aggregate weigh is suspended on four shear beam type load cells thus gives higher accuracy.

Skip Bucket is driven by single two speed geared motor with single brake.

External glass cabin for inspection of entire operation.

Protection mesh provided at bottom of the plant.

Ample space on platform with protective railing for easy maintenance.

Three side glass cabin for Radial Scrapper operator for extensive view.

Fully Automatic-Electronic operation of PLC/PC Control with digital display of each operation.

Maximum weighing accuracy.

Advantages

Compact design and trouble free operation.

Easy to erect as well as dismantle the plant.

Very fewer maintenance of plant, due to less wear and tear parts.

Remarkably cost efficient.

Simple and economical foundations.

Plant operation is very silent & with clean surrounding.

Technical Specifications

Description

Units

MODEL

PRMC-30

PRMC-Bin-30

PRMCH-30

Concrete Output/hr

m3/hr

30

30

30

Type of Mixer

-

Pan Mixer

Pan Mixer

Pan Mixer

Capacity of Mixer

Liter

750/500

750/500

750/500

Aggregate Storage

-

Star Batcher

Inline Silo

Compartment Batcher

No. of Bins / Compartment

No

04

04

04

Active Storage Capacity

m3

25

50

20

Boom Length

Meter

12

-

-

Stock Piles

m3

500

-

-

Aggregate Load Cells

No

04

06

04

Cement Load Cells

No

03

03

03

Water Load Cells

No

01

01

01

Skip Capacity

kg

1500

1500

1500

Cement Capacity

kg

300

300

300

Water Capacity

Ltr

150

150

150

Cement Screw Conveyor

NB

8

8

8

Vibratory Motor

-

Sand / Cement

Sand / Cement

Sand / Cement

Controls

-

Fully Automatic

Fully Automatic

Fully Automatic

Connected Power

kw

60

60

48

Concrete Discharge Height (With raised foundation)

Meter

4.2

4.2

4.2

Total Weight

MT

12

22

20

Note: Output production of Concrete is considered with 30 second mixing time.

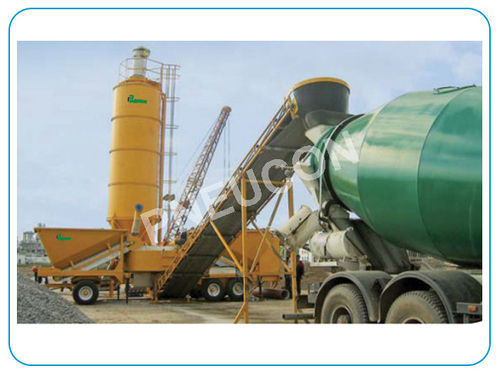

MOBILE CONCRETE BATCHING / MIXING PLANT PMCP SERIES

Mobile

PMCP Series introduces by PNEUCON, for India & Overseas,

indigenously developed Mobile Concrete Batching/Mixing Plant.

The Mobile Concrete Batching/Mixing Plant is a very resourceful product

of PNEUCON machinery; the Plant can produce wet concrete with various

capacities from 12m3/hr. to 25m3/hr. capacity.

This is fully automatic plant with electronic load cell type, weighs

batching system for Aggregates, Cement, Water and additive.

The Pan Mixer suspended with 3 Load cells for weighing of Aggregate,

Cement, Water and additive. The recipes selection is to be entered and

based on the number of batches selected, all operation are carried out

fully automatically i.e. if the plant is set on AUTO mode then

weighing of Aggregate, Cement, Water and Additive and discharge from

mixer are all carried out according to the sequence, for the number of

batches selected.

Salient Features

Available in 12 / 15 / 18 / 20 / 25 m3/hr. capacity.

Rigid construction of main chassis; fabricated from rolled mild steel material.

Mixer PAN type, for continuous mixing.

Replaceable liner Tiles and Tips in the mixer.

Loading of Aggregate/Sand Hoppers by Wheel loader/ Conveyors/ Manually.

Fully automatic plant with Electronic weighing of Aggregate / Sand / Water / Cement.

Microprocessor based control panel with integral computerized batch controller accommodates 25 different mix recipes.

Maximum weighing accuracy.

Plant only requires Electric Power Supply, Water Piping, Aggregate /Sand feeding.

Inbuilt Water and Additive tank.

Easy transportation & shifting by towing also.

Advantages

Very slim and compact design.

Plant can be erected & commissioned within two days.

Remarkably cost efficient.

Plant operation is very silent & with clean surrounding.

Very fewer maintenance of plant, due to less wear and tear parts.

Complete plant can be transported in one 40 foot trailer.

Technical Specifications

Description

Units

MODEL

PMCP-15

PMCP-20

PMCP-25

Concrete Output/hr

m3/hr

15

20

25

Type of Mixer

-

Pan Mixer

Pan Mixer

Pan Mixer

Capacity of Mixer

Liter

600

1000

1250

Sand / Aggregate Hopper

Nos.

04

04

04

Hopper Capacity Each

m3

2.5

3

2.5

No. of Wheels

Nos.

04

06

06

Water Tank

-

Inbuilt

Inbuilt

Inbuilt

Water Pump

Nos.

02

02

02

Additive Tank

-

Inbuilt

Inbuilt

Inbuilt

Additive Pump

No.

01

01

01

Controls

-

Fully Automatic

Fully Automatic

Fully Automatic

Connected Power

kw

36.0

53.0

62.5

Total Weight (Approx)

MT

08

10

12

REVERSIBLE MOBILE MIXER

Reversible

Mobile Mixer is built for easy and fast concreting on concrete jobs

like, Building, Flooring, Road Projects, Bridges, Infrastructure

projects, Canal projects up to the satisfactory performance.

The mixer design is rationalized for easily manorable mixer requiring

very less maintenance, a very practical product of PNEUCON; the Plant

can produce wet concrete from 8m3/hr. to 12m3/hr. capacity. This is

fully automatic mixer with electronic load cell type, weighs batching

system for input ingredients.

Salient Features

Reversible Mixer drum is rotating on well align heavy duty gear ring guided by three rollers for smooth rotation.

Compact design for easy transportation.

Ascent

& Descent of loading skip bucket is controlled by hydraulic pump

(driven by Electric motor) and lever operated direction control valve

and oleo dynamic cylinder.

Power

Transmission done by V Belt pulley and inline gearbox allow a very

cushioned and jerk less revision of drum rotation by very low stress on

mechanical components.

Rotation of the concrete drum, reversed is actioned by push button on the electric control panel.

4 Nos. of pneumatic tyres for proper balancing at the time of toeing.

The lever on the oleo dynamic system distributed controls the skip ascent and descent.

Fully imported Zero resetting water flow meter (Auto-Manual Cutoff).

Digital indicator with Alarm system for weighing of Aggregate and Cement.

Plant only requires Electric Power Supply, Water piping, Agg/ Sand feeding.

Plant operation is very silent & with clean surrounding.

Technical Specifications

Description

Units

MODELS

PRM-10

PRM-12

Concrete Output/hr

m3/hr

10

12

Mixer Batch Capacity

m3

0.45

0.6

Weighing Sale

Aggregate & CementWater

--

Nos.

Nos.

Electronic Digital Display

04 Nos. of Electronic Load Cell

Imported Water Flow meter

Electronic Digital Display

04 Nos. of Electronic Load Cell

Imported Water Flow meter

Water Tank Connection

Liter

175

175

Bucket Lifting

-

Hydraulically

Hydraulically

Water Connection

mm

2 (50) x 1 (25)

2 (50) x 1 (25)

Tyres

Nos. of Pneumatic TyresTyre Size

--

Nos.

PR

--

04 Nos.

06 - 16, 8 PR

--

04 Nos.

06 - 16, 8 PR

Mechanical Jack

Nos.

04 Nos.

04 Nos.

Dimension - Length

mm

4500

5200

TRANSIT MIXER (PTM SERIES)

PTM Series

introduces by PNEUCON, for India & Overseas, indigenously developed

Transit Mixer. The Transit Mixer is a very resourceful product of

PNEUCON Process Technologies; the mixer can produce concrete with

various capacities 2 m3, 4 m3 & 6m3 capacity.

PNEUCON Transit Mixer is a strong well designed piece of equipment

meant for transporting concrete / mortar from concrete batching plant

directly to the place where it is to be poured. It has a wide range of

application especially for mass concreting works like Construction of

Canals, Bridges, Highways, Dams, Multistoried & Industrial

Buildings, Factories, and Airports and for ready mixed Concrete Works

(RMC).

PNEUCON Transit Mixer is fully hydrostatic mounted on truck chassis.

Hydrostatic power is transmitted by a high pressure axial piston type

pump and motor, which permits infinite varying drum speed from 0 to 14

rpm in both directions. The control of pump gives flow to a high

pressure hydraulic motor, which rotates the mixer drum through an

epicyclic gear reducer. The mixer drum has double spiral type mixing

blade inside it which ensures efficient mixing without segregation

& smooth flow of concrete while discharging. The mixer drum &

spiral are made from highly durable steel.

Salient Features

Long life of mixing drum & spirals due to highly durable steel.

Imported hydraulic pump and motor.

Adequate 'Kirloskar' air cooled diesel engine (Slave Engine).

Compact imported oil bath planetary gearbox which absorbs extreme torsion of equipment.

Micro filtration system ensuring hydraulic pump and motor protection.

Hydraulic oil cooler with inbuilt hydraulic tank and filter.

A long trouble free working life due to close loop hydraulic circuit.

Manual rotation of drum possible in case of emergency.

Technically well conceived shape of the mixing spirals which ensures better quality of products.

Mixer drum rotates on machined ring to achieve concentricity & smooth wobble free rotation .

Prepacked and adjustable drum roller assembly to compensate jerks and shocks.

Sturdy chassis design, low center of gravity resulting in better stability of vehicle.

Simple comprehensive operation.

Efficient hydrostatic drive ensuring low fuel consumption.

Technical Specifications

Description

Units

MODEL

PTM-2

PTM-4

PTM-6

Nominal Capacity

m3

2

4

6

Total Geometric Volume

m3

3.95

6.03

11.2

Filling Ratio

%

50.6

50.6

53.2

Drum Speed

RPM

0 - 14

0 - 14

0 - 14

Maximum Drum Diameter

mm

1700

2000

2280

Drum Angle

Degree

15

15

15

Drum & Flight Material

--

ST 52

ST 52

ST 52

Rollers

Nos.

02

02

02

Water pump output press.

bar

5

5

5

Water Tank Capacity

Liters

200

400

500

Water Connection

mm

32

32

32

Prime Mover

Model

HA 394

HA 394

HA 394

Power

kW / HP

24 / 32

40 / 54

52 /70

Drum Length

mm

2830

3500

4380

Drum Width

mm

1950

2000

2280

Height of Charging hopper

mm

3200

3500

3875

Weight of mixer

kgs

2500

3000

3760

Weight of mixer accessories

(Extension chute with holder, ladder)9

kgs

80

80

80

Height of Mixer Frame

mm

150

150

150

Water Line Volume

Ltrs.

2500

4700

7000

Water Level Gauge

Ltrs.

0 - 200

0 - 400

0 - 500

Company Details

Focusing on a customer-centric approach, KI CONEQUIP PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Construction Machinery in bulk from KI CONEQUIP PVT. LTD. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

87

Establishment

2007

Working Days

Monday To Saturday

GST NO

24AAGCK6661A1ZT

Payment Mode

Cheque

Related Products

Explore Related Categories

Seller Details

GST - 24AAGCK6661A1ZT

Dahegam, Gujarat

Proprietor

Mr Suresh Patel

Address

Survey No. 381, Village - Vasna Rathod, Ahmedabad - Dehgam Road, 2 Km Away From Galudan Chaukdi, Tal.Dehgam, Dist. Gandhinagar, Dahegam, Gujarat, 382305, India

mobile batching plant in Dahegam

Report incorrect details