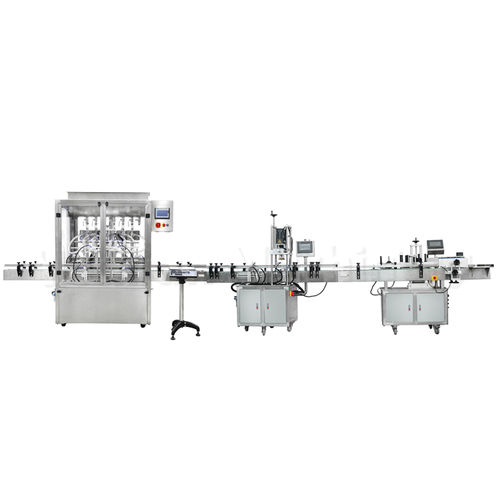

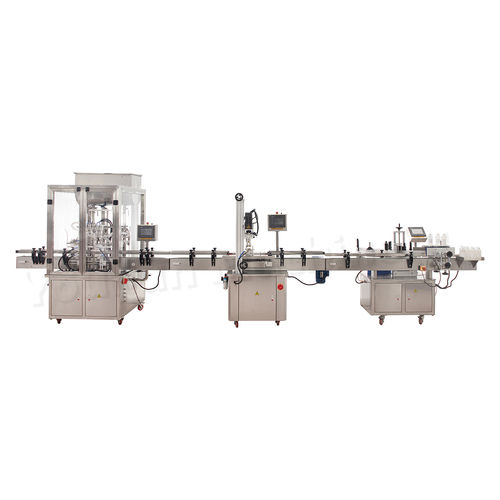

Model Sp-w12-d160 Automatic Filling Machine (1 Line 2 Fillers)

Price Trend: 10000.00 - 1000000.00 USD

Get Latest Price

Minimum Order Quantity :

1 Set

In Stock

Product Specifications

| Power | 3.4 kw |

| Weight (kg) | 450kg Kilograms (kg) |

| FOB Port | Tianjin |

| Payment Terms | Letter of Credit (L/C), Telegraphic Transfer (T/T) |

| Supply Ability | 100 set/year Per Year |

| Delivery Time | 2 months Months |

| Packaging Details | wooden case |

| Main Export Market(s) | Middle East, Africa, Asia |

Product Overview

Key Features

Descriptive abstract

This series machine is a new-designed that we make it on placing the old Turn plate Feeding on one side. Dual auger filling within one line main-assist fillers and the originated Feeding system can keep the high-precision and take off the tiring cleaning of the turntable. It can do the accurate weighing & filling work, and also could combined with other machines to buildup a whole can-packing production line. This machine could be used in filling milk powder, albumen powder, condiment, dextrose, rice flour, cocoa powder, solid drink, and so on.

Main features

One line dual fillers, Main & Assist filling to keep work in high-precision.

Can-up and horizontal transmitting is controlled by servo and pneumatic system, be more accurate, more speed.

Servo motor and servo driver control the screw, keep stable and accurate

Stainless steel structure, Split hopper with polishing inner-out make it to cleaned easily.

PLC & touch screen make it be easy of operation.

Fast-respond weighing system make the strong point to real

The handwheel make the exchange of different filings to be easily.

Dust-collecting cover meet the pipeline and protect environment to pollution.

Horizontal straight design make the machine in little area

Settled screw setup make no metal pollution in producing

Process: can-into a can-up a vibration a filling a vibration a vibration a weighing & tracing a reinforce a weight checking a Can-out

With whole system central control system.

Main Technical Data

Dosing mode : Dual filler filling with online weighing

Filling Weight : 100 - 2000g

Container Size : I 60-160mm; H 60-260mm

Filling Accuracy : 100-500g, a A 1g; a Y500g,a A 2g

Filling Speed : Above 50 cans/min(#502),Above 60 cans/min(#300 ~ #401)

Power Supply : 3P AC208-415V 50/60Hz

Total Power : 3.4 kw

Total Weight : 450kg

Air Supply6kg/cm : 0.2cbm/min

Overall Dimension : 2650A 1040A 2300mm

Hopper Volume : 50L(Main) 25L (Assist)

Deploy List

No.NameModel SpecificationPRODUCING AREA,Brand

1Stainless steelSUS304China

2PLCFBs-60MCT2-ACTaiwan Fatek

3HMISchneider HMIGXO5502Schneider

4Filling servo motorBCH1302N12A1C 1.0kwSchneider

5Filling servo driverLXM23DU10M3X 1.0kwSchneider

6Filling servo motorBCH0802O12A1C 750WSchneider

7Filling servo driverLXM23DU10M3X 750WSchneider

8Servo motorBCH0802O12A1C 750WSchneider

9Servo driverLXM23DU10M3X 750WSchneider

10Agitator motorDRS71S4SEW/SEW-EURODRIVE

11Agitator motorDR63M4SEW/SEW-EURODRIVE

12Gear reducerNRV5010STL

13Electromagnetic valve SMC

14Cylinder SMC

15Air Filter and booster SMC

16motor120W 1300rpm Model: 90YS120GY38Taiwan JSCC

17ReducerRatio:1i 36i Model:90GKi Fi 36RCTaiwan JSCC

18VibratorCH-338-211KLSX

19Switch Schneider

20Circuit breaker Schneider

21Emergency switch Schneider

22EMI FilterZYH-EB-10ABeijing ZYH

23Contactor Schneider

24Heat relay Schneider

25RelayMY2NJ 24DCJapan Omron

26Switching power supply Changzhou Chenglian

27AD Weighing Module MAINFILL

28Loadcell Mettler-Toledo

29Fiber sensor PEPPERL+FUCHS

30Photo sensor PEPPERL+FUCHS

31Level sensorLVL-T1-G3S-E5PG-NAPEPPERL+FUCHS

Company Details

Business Type

Exporter, Manufacturer, Supplier, Trading Company

Employee Count

4

Establishment

2016

Working Days

Monday To Sunday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

Seller Details

Shijiazhuang, Hebei

General Manager

Mr Baolei Zheng

Address

No.86,Xisanzhuang Street, Shijiazhuang, Hebei, 050000, China

Report incorrect details