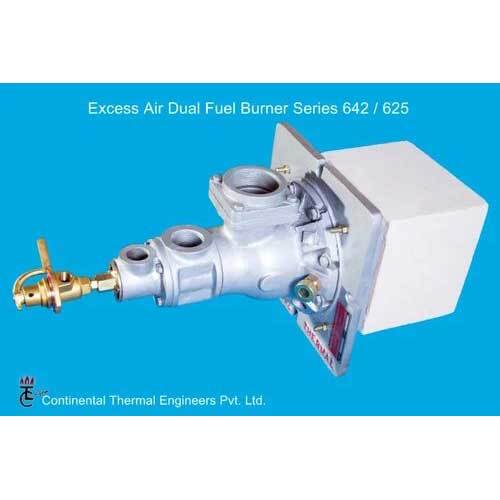

Modulating Dual Fuel Burners By Ecotherm Energy Systems

Price:

Get Latest Price

In Stock

Product Overview

Key Features

Assisted by a competent workforce and advanced production unit, our firm is offering supreme quality Modulating Dual Fuel Burners that are used in oil and gas industry, forging and metallurgy. Offered burners are designed and manufactured by our team of experts with the use of premium grade components and modern manufacturing techniques. The offered Modulating Dual Fuel Burners are made available in various technical specifications as per the exact requirements of our clients. Our provided burners can be easily purchased from us at market leading rates. Features: Unmatched performance Negligible maintenance Robust construction Durability FuelsDifferent fuels can be used depending on the burner model:KP modelsLight fuel oil, viscosity 4 to 12 mm2/s, +20oCRP models Heavy fuel oil, viscosity max. 250 mm2/s, +50oC Heavy fuel oil, viscosity max. 450 mm2/s, +50oC heating cartridge for pump, nozzle and solenoid valves Heavy fuel oil, viscosity max. 650 mm2/s, +50oC heating cartridges as above + trace heating for the oil train GP modelsnatural gas, gases of 2nd family, groups H and E (equipment categories I and I2E)GKP and GRP dual fuel burners Fuel properties as above, natural gas/light fuel oil Fuel properties as above, natural gas/heavy fuel oil Burners using other fuels are available on request. Gas equipmentThe gas-related components of the burner are mounted according to the EN 676 standard: two shut-off valves, pressure switches (min./max.), and an automatic valve proving system. Other train equipment is available on request.Oil lineMounted on the burner, three-stage burners with four solenoid valves (one main valve and one valve for each nozzle). Modulating burners have three solenoid valves. The oil regulator for the modulating burner is located on the oil line returning from the nozzle. The oil filter is located on the suction side of the pump. The two oil hoses enable the burner to be hinged.Flame monitoringAll models are equipped with automatic flame monitoring. In KP and RP models, flame monitoring is taken care of via photocell; in GP, GKP, and GRP models, it is performed via UV cell.Control devicesThe control automatics (control unit) are integrated with the burner. The control unit handles all burner operation phases automatically. In the event of a burner failure, the automatics stop the burner automatically. The modulating burners also incorporate a pre-mounted capacity controller. Subject to additional charge, the burners can be delivered with electronic ratio control.SilencerThe sound level of the burners is low, but, if desired, they can be equipped with a separate silencer to make them even quieter.Optimizing combustion head pressure lossAt an additional charge, the modulating burners can be equipped with a system that optimizes the combustion head pressure loss. The system reduces the amount of excess air and also improves combustion figures for partial burner loads.

Company Details

Focusing on a customer-centric approach, ECOTHERM ENERGY SYSTEMS has a pan-India presence and caters to a huge consumer base throughout the country. Get Burners/Industrial Burners & Incinerators from ECOTHERM ENERGY SYSTEMS at Trade India quality-assured services.

Business Type

Exporter, Importer, Manufacturer, Service Provider, Supplier

Employee Count

6

Establishment

1998

Working Days

Monday To Sunday

GST NO

27AAAFE7144F1ZN

Related Products

Explore Related Categories

Seller Details

GST - 27AAAFE7144F1ZN

Thane, Maharashtra

Accepts only Domestic inquiries

Partner

Mr. Sharad Naik

Address

1/8, Sai Tirth, Siddhath Nagar, Kopri colony, Thane (East), Thane, Maharashtra, 400603, India

dual fuel burners in Thane

Report incorrect details