Cutting Tools, Broaches & Cutters

(15677 products)Product Showcase

Bdc-300 Nc Bandsaw Machine Cutting Capacity: 300 Mm (Round) And 300 X 300 Mm (Rectangle)

9250000 INR

By:

Multicut Machine Tools

Bdc-300 Nc Bandsaw Machine Cutting Capacity: 300 Mm (Round) And 300 X 300 Mm (Rectangle)

Price: 9250000 INR/Unit

MOQ1 Unit/Units

UsageIndustrial

Cutting Capacity300 mm (Round) and 300 x 300 mm (Rectangle)

Cutting Speed15 - 95 m / min m/m

Weight2650 Kg (Automatic) and 2150 Kg (Semi Automatic) Kilograms (kg)

Product TypeBDC-300 NC Bandsaw Machine

MaterialMetal

Multicut Machine Tools

Vadodara

Trusted Seller

Trusted Seller13 Years

Super Premium

Super PremiumTungsten Carbide Hd 4Ft Manual Tile Cutter (1.2 Meter) 1200 Mm

Price: 21000 INR/Unit

MOQ1 Unit/Units

Operate MethodManual

Weight20 Kilograms (kg)

ColorRed

Product TypeHD 4FT Manual Tile Cutter

Size48" (1200 MM)

BladeÃÂ Size22 mm

Mm2mm Products

Navi Mumbai

Trusted Seller

Trusted Seller9 Years

Super Premium

Super PremiumDEMOLITION HAMMER 11 KG

Price: 63100 INR/Piece

MOQ1 Piece/Pieces

UsageIndustrial

SizeStandard

Product TypeDEMOLITION HAMMER 11 KG

ColorBlue

HardnessHard

MaterialSteel

Dynamic Crane Engineers Private Limited

Pune

Trusted Seller

Trusted Seller5 Years

Super Premium

Super PremiumStainless Steel Hss Step Punches

Price: 60 INR/Piece

MOQ25 Piece/Pieces

ShapeStraigt

CoatingPolished

MaterialStainless Steel

Vinay Tools

Thane

Trusted Seller

Trusted Seller7 Years

Super Seller

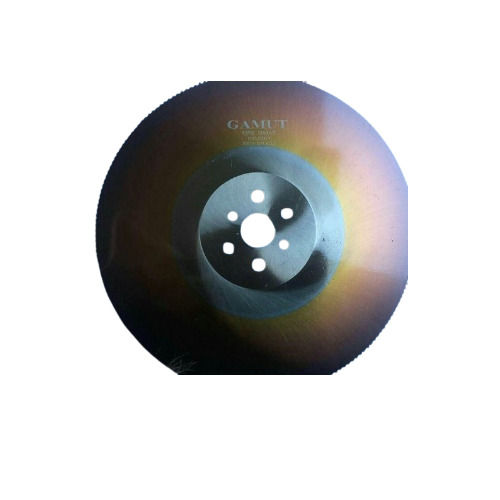

Super SellerGamut High Speed Hss Circular Saw Blade Blade Size: 450 X 2.5 X 32

Price: 13000 INR/Piece

MOQ1 Piece/Pieces

Product TypePipe Cutting HSS Circular saw

Length450 Millimeter (mm)

Cutting Accuracy0.020 mm

ColorCopper

Width450 Millimeter (mm)

CoatingPVD TiCN / TiAlN

Blue 500 Ml Abs Hub Cutter Range

Price: 180 INR/Piece

MOQ100 Piece/Pieces

ShapeCylindrical

Product TypeHub Cutter Range

ColorBlue

UsageCutting

MaterialMetal

Sangam Plastic Industries Pvt. Ltd.

Delhi

Super Seller

Super SellerCross Hatch Cutter Kit (1mm, 2mm, and 3mm)

Price: 2800 INR/Unit

MOQ10 Unit/Units

ColorBlack

Product TypeCross Hatch Cutter Kit

UsageIndustrial

MaterialSteel

14 Inch Gold Line Single Net Green Color Cutting Wheel Cutting Accuracy: 100 %

Price Trend: 100-200 INR/Piece

MOQ10000 Piece/Pieces

Product TypeCUTTING WHEEL

Size14 INCH 355*2.5*25.4 MM

Cutting Accuracy100 %

ColorGREEN

Cutting Speed4400 RPM

MaterialMetal

Credence Livic Industries Llp

Ahmedabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller5 Years

Available In Multicolor Needle Cutter Manual

Price: 90 INR/Piece

MOQ500 Piece/Pieces

Product TypeNeedle Cutter Manual

Pill Cutter

Price: 100 INR/Piece

MOQ100 Piece/Pieces

FeaturesLight Weight

ShapeRectangular

Tool TypeTablet Cutter

Operate MethodManual

ColorYellow

Product TypePill Cutter

Dhritee Impex

Mumbai

Trusted Seller

Trusted Seller3 Years

Premium Seller

Premium SellerWhite Pipe Circular Saws

Price: 3000 INR/Piece

MOQ200 Piece/Pieces

ColorWhite

Height80 Millimeter (mm)

Size300 x 220 x 240 MM

Length80 Millimeter (mm)

MaterialCarbon Steel

Handle MaterialAluminum

Inder Industries

Jalandhar

Trusted Seller

Trusted Seller12 Years

Super Seller

Super SellerTransparent Manual Needle Cutter

Price: 300 INR/Piece

MOQ1000 Piece/Pieces

ShapeCylindrical

ColorTransparent

UsageClinic, Lab and Hospitals

Product TypeNeedle Cutter

Operate MethodManual

MaterialHigh Speed Steel

Orange Vinspire 18 Inch Petrol Chain Saw

Price: 6500 INR/Piece

MOQ1 , Piece/Pieces

UsageTREE CUTTING

ColorOrange

Product TypeChain Saw

HardnessYes

SizeStandard

MaterialHigh Speed Steel

Vinspire Agrotech (i) Private Limited

Ahmedabad

Trusted Seller

Trusted Seller8 Years

Super Premium

Super PremiumAutoline Ii And Autoline Pro Abrasive Cutting Heads - Material: Stainless Steel

MOQ50 Unit/Units

Operate MethodSemi Automatic

UsageIndustrial

CoatingPolished

MaterialStainless Steel

Shape Waterjet Private Limited

Mumbai

Steel Cake Cutter Cum Copra Cutter Machine

MOQ1 Unit/Units

Product TypeCopra Cutter Machine

CoatingPaint coated

UsageIndustrial

Operate MethodSemi - Automatic

MaterialSteel

Processing TypeNormal

Perfect Engineerings

Coimbatore

Trusted Seller

Trusted Seller2 Years

Premium Seller

Premium SellerBlue Rubber Bale Cutter Machine

Price: 400000 INR/Unit

MOQ1 Unit/Units

ColorBlue

UsageIndustrial

Product TypeRubber Bale Cutter Machine

MaterialSteel

Body MaterialOther, Cast iron

ForceHydraulic Meganewton (MN)

Santec Exim Private Ltd

Gurugram

Trusted Seller

Trusted Seller23 Years

Super Seller

Super SellerBlue & White Upvc Glazing Bead Saw

Price: 250000.00 INR/Piece

MOQ1 Piece/Pieces

Size1350x500x1350mm

Product TypeUPVC Glazing Bead Saw

ShapeRectangle

ColorBlue & White

Weight210 Kilograms (kg)

Zenith Engineering And Equipments Private Limited

Vadodara

Premium Seller

Premium SellerBrush Cutters - Premium Quality Build | Ergonomically Designed Handle, Easy to Use, Ideal for Light to Heavy Duty Jobs

Payment TermsCash on Delivery (COD), Cash Against Delivery (CAD), Cheque

Main Export Market(s)Asia

Dharmatech Industries

Ahmedabad

Trusted Seller

Trusted Seller9 Years

Premium Seller

Premium SellerSilver Stainless Steel Copra Cutter

Price: 13570 INR/Unit

MOQ1 Unit/Units

ColorSilver

UsageCommercial

Product TypeStainless Steel Copra Cutter

MaterialStainless Steel

Gorek Technologies

Surat

Trusted Seller

Trusted Seller8 Years

Super Seller

Super SellerBlue Bosch Chop Multicut Saw

Price: 14850 INR/Unit

MOQ1 Unit/Units

UsageIndustrial

ColorBlue

Product TypeBosch Chop Multicut Saw

SizeDifferent Size

ShapeRound

MaterialSteel

Adrija Scientific Instrument Company

Kolkata

Trusted Seller

Trusted Seller4 Years

Super Seller

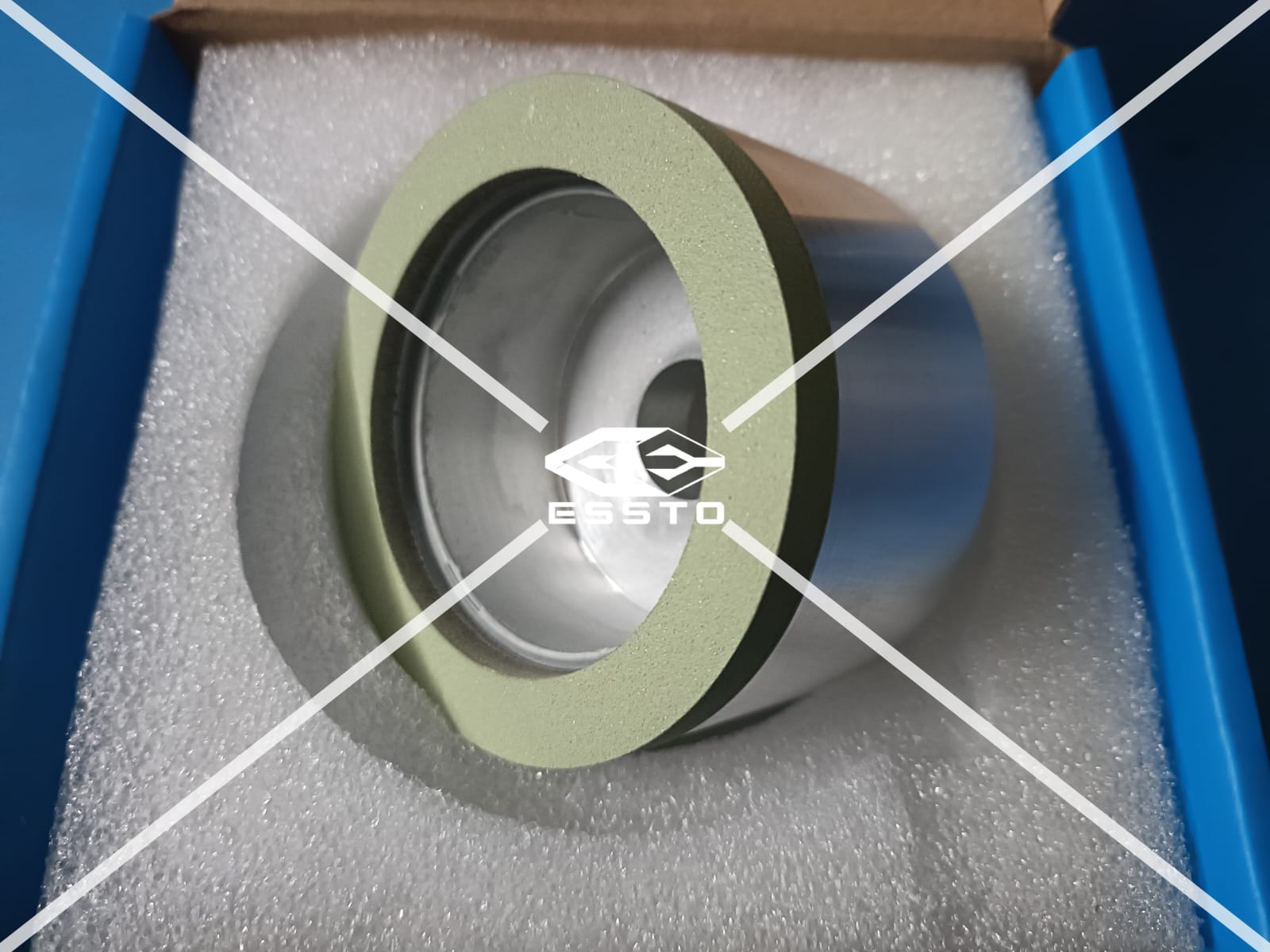

Super SellerSilver Grinding Wheel For Pcd Tool Grinding

Price: 5500.0 INR/Number

MOQ1 Number

SizeStandard

ShapeRound

UsageIndustrial

HardnessYes

ColorSilver

MaterialHigh Speed Steel

Essto Engineering ( Unit - Ii )

Burdwan

Trusted Seller

Trusted Seller8 Years

Premium Seller

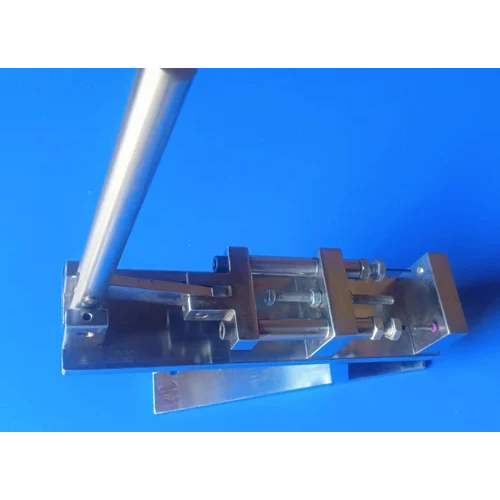

Premium SellerHigh Speed Steel Adjustable Cutter

Price: 50 INR/Piece

MOQ500 Piece/Pieces

ColorBlack

UsageIndustrial

Product TypeCutting Tools

MaterialHigh Speed Steel

Vinay Engineering Company

Vasai

Trusted Seller

Trusted Seller8 Years

Premium Seller

Premium SellerA-4 Hydraulic Fusing Machine 100 Cards ( Double Chamber) - Color: Blue

Price: 185000 INR/Piece

MOQ1 Piece/Pieces

Weight150 Kilograms (kg)

UsageIndustrial

Product TypeA-4 Hydraulic Fusing Machine 100 Cards ( Double Chamber)

Size630x490x640mm

ColorBlue

Gb Tech (india)

Delhi

Trusted Seller

Trusted Seller19 Years

Super Seller

Super SellerHandheld Plastic Hep2O Pipe Diameter Cutter

Product TypePipe Diameter Cutter

UsageUsed for pipe diameter cutting

ColorRed

Diameter28 Millimeter (mm)

Wavin Industries Limited

Noida

Trusted Seller

Trusted Seller11 Years

Super Seller

Super SellerRock Cutting Cum Grinding Machine Voltage: 440 Volt (V)

Price: 1.00 INR/Piece

MOQ1 Piece/Pieces

Voltage440 Volt (v)

Power Supply440 Volt, 50Hz, Single Phase, AC Supply

Eie Instruments Private Limited

Ahmedabad

Trusted Seller

Trusted Seller15 Years

Super Seller

Super SellerIndustrial Drill Rods Hardness: Hard

Price: 1300 INR/Piece

MOQ10 Piece/Pieces

Product Type8613804

UsageIndustrial

SizeDifferent Sizes Available

CoatingPolished

HardnessHard

MaterialStainless Steel

Klr Industries Limited

Hyderabad

Trusted Seller

Trusted Seller3 Years

Super Seller

Super SellerCopper Coated Saw Wire - Diameter: Diameter 2.5Mm

Price: 1250 INR/Kilograms

MOQ50 Kilograms/Kilograms

CoatingCopper

Product TypeCopper Coated Saw Wire

UsageIndustrial

ColorCopper

Diameter2.5, 3.2 & 4.0 Millimeter (mm)

D & H Secheron Electrodes Private Limited

Indore

Trusted Seller

Trusted Seller5 Years

Super Seller

Super SellerLatest From Cutting Tools, Broaches & Cutters

RICHARD Cutting Tools, Broaches & Cutters

By:

Richard Sales Corporation

Knives Tool

By:

Shuen - Li Machinery Co., Ltd.

Crimp Analysis And Tools

By:

Uwc Resources (m) Sdn. Bhd.

Needle Sets

By:

Mean Light Co.

Explore More Cities

Ready To Ship Cutting Tools, Broaches & Cutters

What is it & why is it important - Cutting Tools, Broaches & Cutters

The manufacturing of machines relies heavily on cutting tools. Cutting tools are essential in the machine industry since, without them, many of the most important procedures simply cannot be completed. When it comes to cutting, milling, drilling, and other similar processes used in the manufacturing of machines, engineers need access to the most advanced cutting equipment available.

A broaching tool, also known simply as a broach, is a type of cutting tool used to remove material from the inside diameter of a workpiece in order to create the desired shape. Typically, the broach will be utilized in a lathe or coupled to a machine that operates under hydraulic pressure.

1. Time Effective

It is widely acknowledged that efficient cutting tools are a must-have for any machine industry worker concerned with efficiency and productivity. In the end, it doesn't matter if the products are of great quality or if the deadline is met. Therefore, it is essential for such facilities to have efficient engineering machine tools to guarantee the highest quality output within the stipulated time frame.

2. Efficiency

In the manufacturing sector, the values of individual parts are meaningless unless they achieve the required levels of efficiency. Although metal-cutting tools only account for a small percentage of production costs (estimates range from 3–5%), studies have shown that by selecting the tools best suited to the task at hand, factories can reduce their total operating expenses by as much as 15 percent.

3. Better Productivity

When it comes to the machine industry, the distinction between a lucrative subset and a losing subset is found in the levels of effective productivity. Using high-quality components and gear to do daily chores is analogous to employing effective Cutting Tools, Broaches & Cutters. As a result, it stands to reason that a unit's production will naturally peak when all of the necessary components are of high enough quality to get the job done.

Difference between Cutting Tools, Broaches, and Cutters

Cutting Tools VS Broaches VS Cutters

- Cutting Tools: To obtain the desired shape, size, and precision in machining, a cutting tool, often a wedge-shaped or razor device is employed to shear away an extra layer of material from the workpiece. It has a fixed position on the machining center. Several mechanical and non-mechanical systems for cutting action also give a relative velocity between the workpiece and the cutting tool.

- Broaches: The broach is the tool used in the broaching process. The rise per tooth is one of the most important characteristics of a broach since it reveals how much material is removed by each tooth with each pass. Along the length of the tool, these teeth are separated into three distinct regions: the roughing, intermediate, and finishing regions. Broaching is a type of machining in which a toothed tool is used to precisely and repeatedly remove material. Manufacturing broaching is normally only utilized for precise applications and high-quantity production, although there are two types of broaching services available (linear and rotary) that are used to create distinct sorts of machining finishes.

- Cutters: To achieve the proper shape, size, and accuracy in machining, cutting tools, which are wedge-shaped and have sharp edges, are used to shear away extra layers of material from a workpiece. Its hold on the machining center is rock solid. Multiple mechanical and non-mechanical mechanisms contribute to the cutting process by providing a relative velocity between the substrate and the cutting tool.

What are the objectives of Cutting Tools, Broaches, and Cutters?

Cutting tools are used to precisely remove material from a workpiece. The material being cut is subjected to a compressive force from the tool, which pushes the material past its yield point. The metal was plastically deformed and then sheared off. Shear planes are the specific locations of plastic flow.

Example:

- Hardware such as a saw, a broach, a drill bit, a fly cutter, etc.

- In order to cut effectively, you must take into account:

- Tool and material hardness

- The pressure exerted on a workpiece

- Geometry of Tools

Another factor that affects productivity is how sharp the instruments are. Cutting and slicing tasks are made easier thanks to the sharp edges' ability to make minimal touch with the material being worked. High pressure and temperature differences are experienced by the cutting tool throughout the machining process. So, it's important to choose the right materials for your tools.

You can categorize the various types of cutters by

To the extent that there are sharp edges in use:

1. Useful for planning, sculpting, turning, etc.; have only one cutting edge.

2. In milling, drilling, and other similar processes, it is common to utilize a multipoint tool, which has multiple active cutting edges.

In accordance with the cutting motion tool,

1. Instruments for cutting in a straight line - Example: cutting tools, broaches

2. The use of rotary instruments -Example: instruments such drills, milling cutters, reamers, counterbores, etc.

Different types of Cutting Tools, Broaches, and Cutters

1. The Broach

A broach is a special kind of cutter with graduated rows of teeth. Any kind of cut, from the simplest to the most intricate, may be made swiftly and precisely with a broach.

2. Liner Broaching

Cuts are made as the tool travels in a straight line across the surface of the workpiece. There is a good illustration of linear broaching in the diagram.

3. Pull Broaching

When performing pull broaching, the workpiece is clamped in place and the broach is withdrawn from the material. Broaches of the length and configuration required for this procedure are uncommon.

4. Carbon Tool Steel

Carbon-based tool Steel is commonly utilized as a low-cost metal cutting tool in machining operations that need a high degree of precision. These plain carbon steel cutting tools include between 0.6% and 1.5% carbon and less than 0.5% Mn and Si. The hardness and grain size can be adjusted by adding other metals like Cr and V.

5. High Speed Steel (HSS)

To increase its hardening ability, toughness, and wear resistance, this high-carbon steel has been heavily alloyed with elements like tungsten, molybdenum, chromium, etc. There is greater efficiency in metal removal.

6. Single Point Cutting Tool

A single-point cutting tool has a single, centralized cutting edge that can be used for many material-cutting tasks simultaneously. Activities like turning, sculpting, and planning necessitate the use of single-point cutting tools.

7. Double Point Cutting Tool

Both cutting and shearing can be accomplished with a single stroke of a double-pointed cutting tool's blade. A single-point cutting tool, on the other hand, has just a single, dedicated cutting edge.

8. Push Broaching tool

Because of the high compression pressures experienced during push broaching, the tool is made shorter. Compressive forces can bend or break the fewer teeth it has. Reduced part size is achieved through shorter cuts made possible by push broaching.

9. Pot Broaching Tool

The tool holder for pot broaching, which is used for cylindrical workpieces, is designed like a pot. By pushing or pulling the workpiece through a stationary tool, pot broaching achieves its desired shape. When used in conjunction with or as a replacement for other machining processes, pot broaching generates a cut in the opposite direction of interior broaching.

10. Cemented Carbide tool and cermet

The powder metallurgy process is used to manufacture the cemented carbide cutting tool. When the binder is nickel or molybdenum, the mixture is termed cermets, but when it's cobalt, it's called cermets.

11. Ceramics

Aluminum oxide and silicon nitride are the most frequently used ceramic materials. High-temperature sintering of ceramic powder compressed into an insert form. In addition to being resistant to corrosion, ceramic tools are also chemically inert.

12. Glass Cutting Tool

It's the priciest and toughest substance ever discovered. It has a high melting point and thermal conductivity. Diamond has a low friction coefficient and thermal expansion, making it a great material for cutting and polishing. It finds application in the processing of extremely tough materials such as carbides, nitrides, glasses, etc.

13. Spline Broaching

Broaching in the shape of a spline can produce a variety of spline and tooth profiles, including those that are round, plain, or irregular. It's useful for making shafts, gears, and other components that mesh mechanically. The most frequent kind of broaching is called "spline broaching," and it involves using a broach to create a series of ridges or teeth around the outside of a hole that has already been drilled.

14. Blind Braching

When the broaching tool does not go all the way through the part, creating the hole, the procedure is called blind broaching.

Conclusion

Broaching is a type of precision machining in which a sharp, hardened toothed tool is used to remove material from the workpiece in a uniform, steady, and precise manner. Even at high temperatures, the material of the cutting tool must be harder than the material of the workpiece.

In the machine sector, using the most up-to-date and high-quality cutting tools is essential for maximizing efficiency and delivering the finest possible results within the allotted period of time.

FAQs: Cutting Tools, Broaches & Cutters

Q. Applications of cutting tools, broaches & cutters

Ans. A broach, or broach tool, is a type of cutter used to remove material from the inside diameter of a workpiece to create the desired shape.

Q. Cutting tools, broaches & cutters price in India

Ans. The price of cutting tools is between RS 500- Rs15,000 in India.

Q. The function of Cutting Tools, Broaches & Cutters?

Ans. A cutting tool, also known as a shear, is a wedge-shaped implement with sharp edges that is used to tear away unwanted portions of a working item. By cutting away unnecessary bulk, the desired form and dimensions can be realized.

Q. What to look for before purchasing Cutting Tools, Broaches & Cutters?

Ans. However, there is no such thing as a perfect cutting tool material due to competing tradeoffs between qualities like hardness and toughness.

Manufacturers & Suppliers of Cutting Tools, Broaches & Cutters

Company Name | Member Since |

|---|---|

Santec Exim Private Ltd Gurugram, India | 23 Years |

Gb Tech (India) Delhi, India | 19 Years |

Samruddhi Industries Ahmedabad, India | 18 Years |

Gamut Machine Tools Dombivli, India | 15 Years |

Eie Instruments Private Limited Ahmedabad, India | 15 Years |

Energie Kolkata, India | 14 Years |

Multicut Machine Tools Vadodara, India | 13 Years |

Inder Industries Jalandhar, India | 12 Years |

Zenith Engineering And Equipments Private Limited Vadodara, India | 11 Years |

Wavin Industries Limited Noida, India | 11 Years |

Popular Products