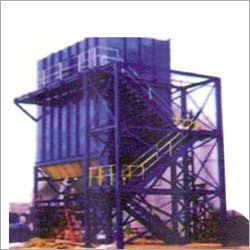

Online Baghouse

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Metal Cage |

| Bag Type | Pulse Jet |

| Air Manifold | Common Air |

| Dust Cake | Dislodged |

| Collection Hopper | Below |

| Product Type | Baghouse |

| Features | Durable, Low Power, Long Life, Removes Pollutants, Quality Tested, Feasible Prices']['Efficient Filtration, Dust Collection, Durable Design, Easy Maintenance |

Product Overview

Key Features

Bags are cleaned by a short burst of compressed air injected through a common air manifold over a row of bags. The compressed air is accelerated by a venturi nozzle mounted at the reverse-jet baghouse top of the bag. Since the duration of the compressed-air burst is short (generally, less than 0.1seconds), it acts as a rapidly moving air bubble, traveling through the entire length of the bag and causing the bag surfaces to flex. This flexing of the bags breaks the dust cake, and the dislodged dust falls into a collection hopper below.

Company Details

Focusing on a customer-centric approach, ECOMAK SYSTEMS PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Get Engineering Goods & Equipment from ECOMAK SYSTEMS PVT. LTD. at Trade India quality-assured services.

Business Type

Exporter, Manufacturer, Service Provider, Supplier, Trading Company

Employee Count

50

Establishment

1993

Working Days

Monday To Saturday

GST NO

27AAACE4087G1ZN

Payment Mode

Cheque, Others

Certification

9001:2008

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AAACE4087G1ZN

Pune, Maharashtra

Purchase Manager

Mr. Rahul

Address

Unit No. 201-C, 2nd Floor, Street No. 268, Mantri Alpine, Bavdhan, Mumbai - Bangalore Highway, Tal: Mulshi, Pune, Maharashtra, 411021, India

baghouse dust collector in Pune

Report incorrect details