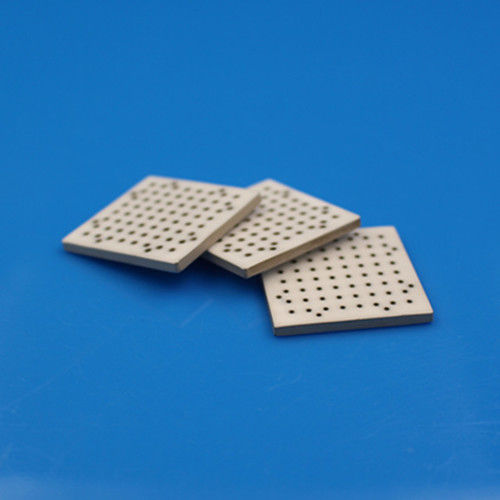

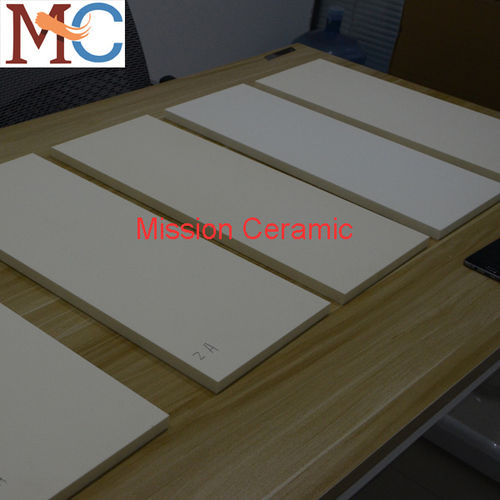

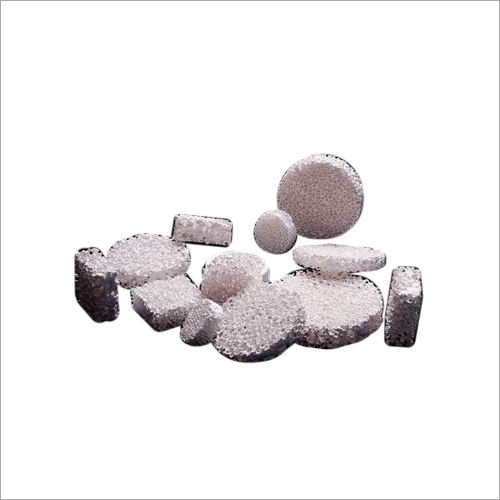

Photocatalyst Foamed Alumina Ceramic Filter Diameter: 40-500 Millimeter (Mm)

Price: null USD ($)

Get Latest Price

Minimum Order Quantity :

500 Piece

Product Specifications

| Warranty | Three years |

| Type | Industrial Depth Filter Cartridge |

| Inlet Diameter | 40-500 Millimeter (mm) |

| Pressure | 0.8 kpa |

| Width | 40-500 Millimeter (mm) |

| Product Type | mass production |

| Size | 40-500 |

| Pore Size | 10-50ppi |

| Color | white |

| Usage | The catalyst is coated on the filter plate and installed in the purification equipment. |

| Shape | Round ,square ,custom geometric shapes |

| Diameter | 40-500 Millimeter (mm) |

| Height | 15-50 Millimeter (mm) |

| Weight | 25-6000 Grams (g) |

| Cartridge Style | Double Open End |

| Filter Rating | 2-45kg/s |

| Filter Media | Other |

| Efficiency | 80-90% |

| Application | Photooxygen catalytic equipment for industrial waste gas treatment, air purifiers and air conditioners equipped with photooxygen catalytic function, etc |

| Length | 40-500 Millimeter (mm) |

| Outlet Diameter | 40-500 Millimeter (mm) |

| Material | Other |

| Delivery Time | 15-25 Days |

| Certifications | Features Low wind resistance, high decomposition efficiency, no powder removal, sufficient coating thickness, no odor, customized size,customized frame, high temperature resistance, corrosion resistance. Usage Photooxygen catalytic equipment for industrial waste gas treatment, air purifiers and air conditioners equipped with photooxygen catalytic function, etc Product working principle: Alumina foam ceramic filter plate are mainly used in the purification process of aluminum and aluminum alloy production, and also applied to various gas-solid, liquid-solid separation media, catalyst carriers, burners and sound-absorbing environmental protection. It can effectively remove all kinds of fineness in the aluminum water to the micron-sized inclusions, make the aluminum water into a smooth laminar flow, which is beneficial to the punching type; it has excellent aluminum washability, tightly controlled hole size and through hole Rate, a stable filtration effect can be obtained; thereby improving casting quality, reducing casting rejection rate, extending service life and reducing casting cost. Due to the good cross-linked macroporous structure and large specific surface area, alumina porous ceramic plate are used as photocatalyst supports for TiO 2 catalysts. Their photocatalytic activity is characterized by the degradation of methyl blue under ultraviolet irradiation. The TiO2 coating prepared by the sol-gel method showed excellent adhesion to the substrate. When the solid content of the carrier reached 15wt%, the TiO 2 coating showed the highest photocatalytic efficiency, which was 79.52%. In addition, the TiO2 film has almost the same photocatalytic activity as the titanium dioxide/water suspension. Therefore, the honeycomb ceramics prepared by the self-organization process is expected to be used as a photocatalyst carrier in water purification without powder recycling. Through strict control and requirements on formulations, carriers, etc., our company achieves high-efficiency photo-oxygen catalysis of photocatalyst series products, which greatly improves the processing efficiency of formaldehyde and tvoc gas, and adapts to the use of products for various purposes to the greatest extent. working environment. |

| Sample Policy | Free samples available with shipping and taxes paid by the buyer |

| Sample Available | 1 |

| Main Export Market(s) | North America |

| Main Export Market(s) | Eastern Europe |

| Main Export Market(s) | Africa |

| Main Export Market(s) | Central America |

| Main Export Market(s) | Middle East |

| Main Export Market(s) | South America |

| Main Export Market(s) | Australia |

| Main Export Market(s) | Asia |

| Main Export Market(s) | Western Europe |

| Payment Terms | Delivery Point (DP) |

| Payment Terms | Days after Acceptance (DA) |

| Payment Terms | Letter of Credit (L/C) |

| Payment Terms | Telegraphic Transfer (T/T) |

| Payment Terms | Western Union |

| Payment Terms | Letter of Credit at Sight (Sight L/C) |

| Supply Ability | 4000000 Per Year |

| Main Domestic Market | All India |

| Packaging Details | carton and pallet |

| FOB Port | TIANJIN SHANGHANG ,CHINA |

| GSTIN | 0% |

Company Details

Business Type

Exporter, Importer, Manufacturer, Supplier

Employee Count

300

Establishment

2013

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Certification

ISO 9001:2015

Related Products

Explore Related Categories

Seller Details

Cangzhou, Hebei

Sales Manager

Ms Kerry

Address

Guanting Industrial Park, Cangzhou City, Hebei Province China, Cangzhou, Hebei, 061034, China

alumina ceramic plate in Cangzhou

Report incorrect details