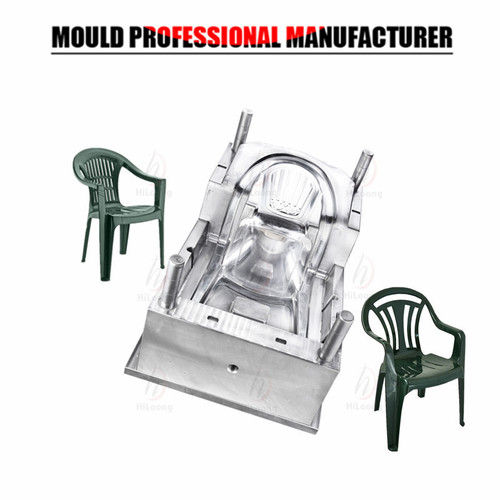

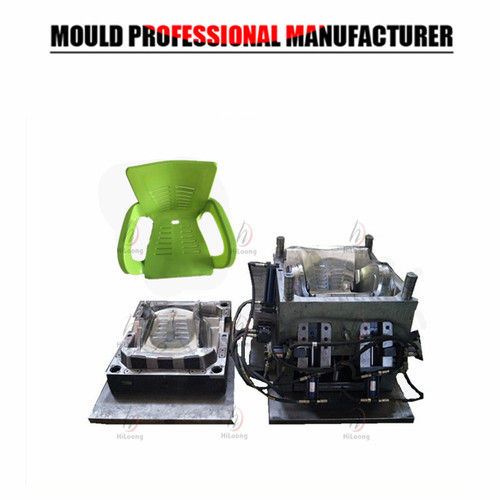

Plastic Chair Shell Injection Mould - P20, 718h, 718hh, 2738 Materials | Multi-cavity Mould With Hot/cold Runner Systems

Price Trend: 8000.00 - 15000.00 USD

Get Latest Price

Minimum Order Quantity :

1

Product Specifications

| Plastic Material | PP |

| Surface Treatment | Other |

| Payment Terms | Telegraphic Transfer (T/T), Letter of Credit at Sight (Sight L/C) |

| Supply Ability | 5 Per Month |

| Delivery Time | 2-3 Months |

| Sample Policy | Contact us for information regarding our sample policy |

| Main Export Market(s) | Middle East, Western Europe, Africa, South America, Asia, North America |

Product Overview

Key Features

Details:

Mould material : P20, 718H, 718HH, 2738, H13, NAK80, S136, CENA-1 etc.

Mould base : LKM, HASCO, DME etc.

Mould spare parts : DME, HASCO, MISUMI, PUNCH etc.

Cavity : single/multi

Runner : hot/cold

Mould life : 500, 000-2, 000, 000 shots

Design software : UG, PROE, SOLIDWORKS, CAD, etc.

Plastic material : PP, PC, PE, PS, PU, ABS, PVC, PA, POM, PMMA, PET, PPR etc.

Delivery time : 45-60 Days

Package : Wooden Case

Delivery : By Sea, by air

Specifications : Depends on customera s special requirements

Process Machine : CNC milling, CNC engraving, EDM, Wire Cutting, Deep Hole Driller Machine, Precised Grinder, etc.

Company Details

Business Type

Manufacturer, Supplier

Employee Count

40

Establishment

2017

Working Days

Monday To Sunday

Payment Mode

Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

Seller Details

Taizhou City, Zhejiang

Sales Manager

Ms Lacey Wu

Address

No.1, BeiYuan Avenue, North Industrial Area, Huangyan, Taizhou City, Zhejiang, 318020, China

injection moulds in Taizhou City

Report incorrect details