Moulds

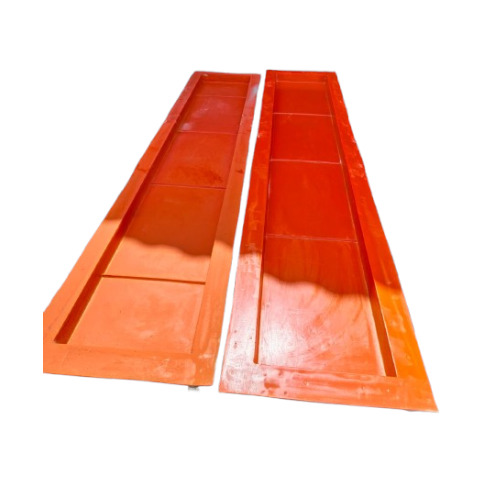

(21158 products)Robust Fiberglass Waffle Mould

Product DescriptionWe are providing our customer a wide range of FRP Waffle Moulds, which are manufactured from high grade quality raw materials. These FRP Waffle Moulds are widely known for its durability and quality. These FRP Waffle Moulds are available at industrial leading price

Everest Composites Pvt. Ltd.

Vadodara

Super Seller

Super SellerIndustrial Rubber Diaphragm - Silicone Material, Customizable Size, Black Color, -40°C to 230°C Temperature Range

Price: 50 INR/Piece

MOQ100 Piece/Pieces

SizeDifferent Size Available

ColorBlack

UsageIndustrial

Product TypeIndustrial Rubber Diaphragm

MaterialOther, Silicone

Kp Rubber & Polymer

Vadodara

Super Bonanza

Super Bonanza Super Premium

Super PremiumKitchen Silicone Mould Size: All Size

Price: 50 INR/Piece

MOQ100 Piece/Pieces

Product TypeSilcone Cake Mould

MaterialOthers

SizeAll Size

Nisarg Polymers Pvt Ltd.

Vasai

Trusted Seller

Trusted Seller9 Years

Super Seller

Super SellerJetpack Machines Pvt. Ltd.

Vasai

Trusted Seller

Trusted Seller8 Years

Premium Seller

Premium SellerFrp Chair And Table Mould - Color: As Per Requirement

Price: 14500 INR/Piece

MOQ10 Piece/Pieces

ColorAs Per Requirement

Product TypeFRP Mould

UsageIndustrial

Life Span1-2 Years

Shaping ModeExtrusion Mould

MaterialFRP, Other

Mahadev Engineering Works

Faridabad

Trusted Seller

Trusted Seller2 Years

Premium Seller

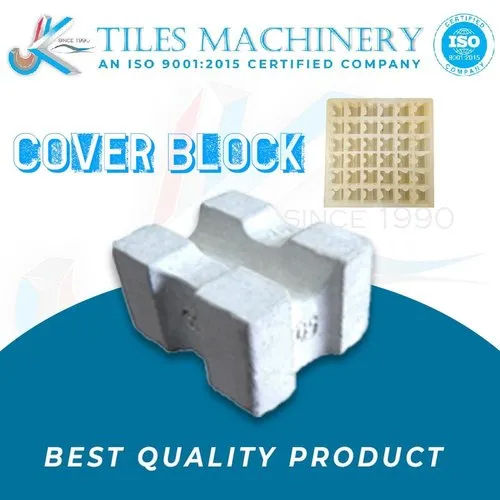

Premium SellerMould For Cover Block - Color: White

Price: 560 INR/Piece

MOQ100 Piece/Pieces

Product TypeMould For Cover Block

SizeStandard

UsageCement Cover Block Manufacturing

ColorWhite

MaterialOther, PVC

J K Tiles Machinery

Hyderabad

Trusted Seller

Trusted Seller4 Years

Super Seller

Super SellerCube Testing Machine - Robust Metallic Design | Enhanced Precision Testing, User-Friendly Interface, Compact Footprint

Price: 48000 INR/Unit

MOQ1 Unit/Units

Supply Ability100 Per Week

Delivery Time3 Days

Main Domestic MarketMizoram, Tripura, Odisha, Assam, Meghalaya, East India, Chhattisgarh, Jharkhand, West Bengal, Bihar, Nagaland, Sikkim, Manipur

Adrija Scientific Instrument Company

Kolkata

Trusted Seller

Trusted Seller4 Years

Super Seller

Super SellerCorrugated Box Shredder Cutting Speed: 35 Rpm

Price: 330000 INR/Unit

MOQ1 Unit/Units

Weight60 to 1500 Kilograms (kg)

TypeSherdder machine

UseCorrugated Box , cardboard shredder

Sheet Capacity2 to 10 folded boxes, boards, whole box

Cutter TypeRegular roll, Toothed roll, Serrated roll

Cut Size6 - 12 mm

Amey Shredtech Private Limited

Thane

Trusted Seller

Trusted Seller18 Years

Super Seller

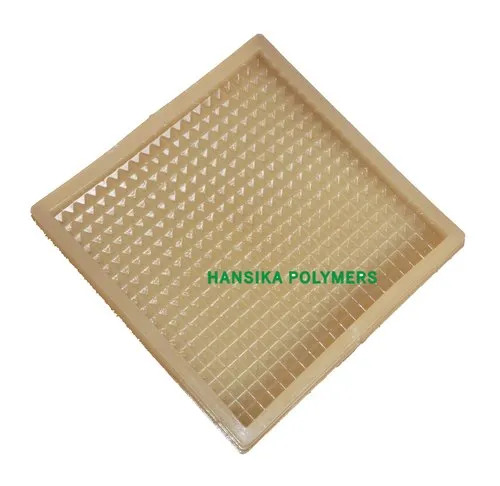

Super SellerCrack Resistant Portable And Durable Rubber Paver Mould

UsageCommercial

ColorRed

Product TypeRubber Paver Mould

Laxmi Engineering Works

Ahmedabad

Trusted Seller

Trusted Seller11 Years

Super Premium

Super PremiumAluminium Moulds and Silicon Moulds

Product DescriptionAluminium Moulds and Silicon Moulds

Shanghai Fude Machinery Manufacturing Co., Ltd.

Shanghai

Trusted Seller

Trusted Seller13 Years

Super Seller

Super SellerRubber Ring Joint Cement Pipe Mould - Life Span: Long Life

Price: 155000 INR/Unit

MOQ1 Unit/Units

Molding MaterialCement Pipe

Life SpanLong Life

SizeAs Per Requirement

UsageIndustrial

Shaping ModeDie-Casting

MaterialSteel

S.k Industries

Upleta

Trusted Seller

Trusted Seller2 Years

Premium Seller

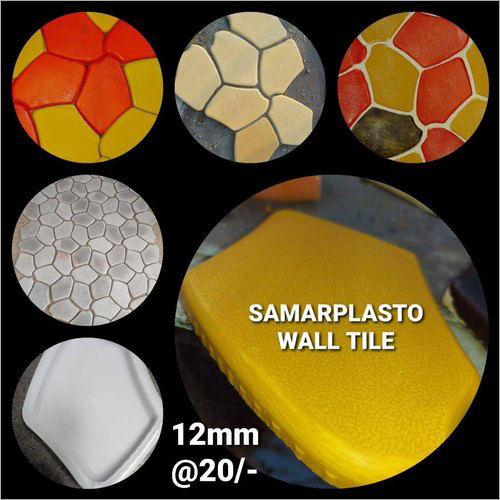

Premium SellerWall Pebble Plastic Mould

Price: 30 INR/Piece

MOQ100 , Piece/Pieces

Product DescriptionWall Pebble Plastic Mould

Samar Buildware Products

Bathinda

Trusted Seller

Trusted Seller4 Years

Premium Seller

Premium SellerMetal Soil Proctor Mould

Price: 1800 INR/Piece

MOQ10 Unit/Units

UsageIndustrial

SizeCustomize

MaterialMetal

Shell Moulding - Custom and Standard Specifications | Superior Surface Finish, Enhanced Dimensional Tolerances, Minimal Machining Requirements

Product DescriptionWith the hep of our dexterous professionals, we have been able to offer the clients a wide range of Shell Moulding. Our products are extensively used in various industrial applications of producing simple or complex near net shape castings, maintaining tight tolerances and high dimensional stability

Bk Tech Enterprise Inc.

Rajkot

Trusted Seller

Trusted Seller6 Years

Super Seller

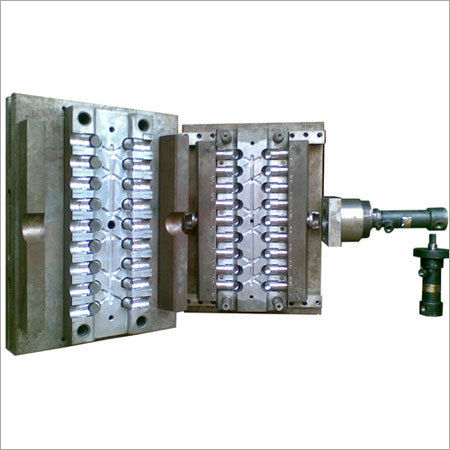

Super SellerBarrel Mould

Product DescriptionWe have gained expertise in manufacturing and supplying a wide array of Barrel Mould. These offered moulds are manufactured using superior quality raw material and advanced technology as per the set industry standards. These moulds are used in diverse industries. These offered products are made avai

Pam Industrial Plastics

Navsari

Trusted Seller

Trusted Seller9 Years

Super Seller

Super SellerPvc Silicone Mould - Life Span: 10 Yrs

Price: 375 INR/Piece

MOQ500 Piece/Pieces

Product TypePVC Mould

Life Span10 Yrs

Mold BasePVC

UsagePaver Block Production

Molding MaterialRubber

Bharat Tiles Machine Product

Noida

Trusted Seller

Trusted Seller8 Years

Premium Seller

Premium SellerMS Brick Mould 15 Cavity

Price: 150000 INR/Set

MOQ10 Set/Sets

Supply Ability50 Per Month

Delivery Time10 Days

Kailash Engineering

Morbi

Trusted Seller

Trusted Seller8 Years

Super Seller

Super SellerBlue Cast Iron Cube Mould

Price: 650 INR/Unit

MOQ100 Unit/Units

ColorBlue

SizeDifferent Size

Weight7.5 Kilograms (kg)

UsageIndustrial

Product TypeCast Iron Cube Mould

MaterialIron

Rcon Engineering

Rajkot

Trusted Seller

Trusted Seller3 Years

Super Seller

Super SellerCube Mould - High Grade Raw Material | Quick Concrete Cube Creation, Durable Design for Testing

Price: 750 INR/Set

MOQ1 Set/Sets

Product DescriptionWe are one of the leading manufacturers and suppliers of Mould Cube from Rajkot, Gujarat, India. The offered mould cube is very widely used for the concrete testing procedures. Our supplied mould cubes are capable of creating a concrete mould which will be tested for withstanding high pressure in

Balaji Construction Machinery

Rajkot

Trusted Seller

Trusted Seller14 Years

Super Seller

Super SellerDie Spring For Press Dies And Moulds

Product DescriptionBacked a team of hardworking professionals, we have been able to manufacture, export and supply an exclusive array of Die Spring For Press Dies And Moulds in Faridabad, Haryana, India. Designed with ultra-grade components other raw material at our well developed manufacturing unit. Our customers can

Ve To Clamping Systems Private Limited

Faridabad

Trusted Seller

Trusted Seller7 Years

Premium Seller

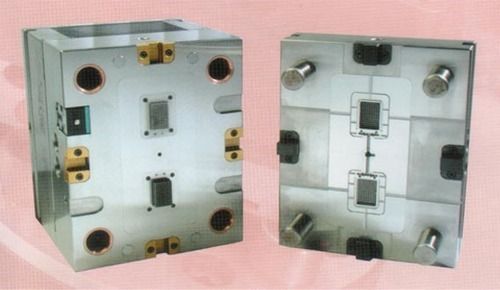

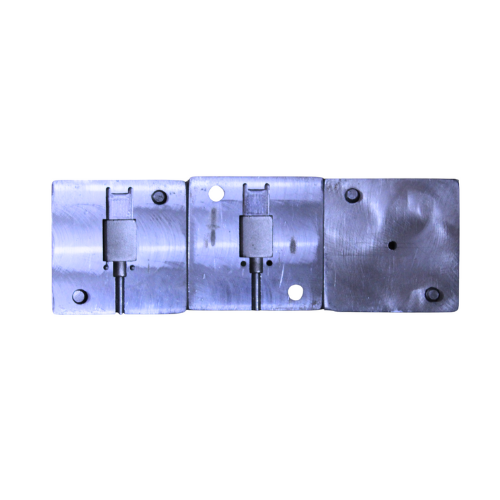

Premium SellerPlastic Injection Moulding Die - Color: Silver

Price: 500000 INR/Piece

MOQ1 Piece/Pieces

ColorSilver

SizeStandard

Product TypePlastic Injection Moulding Die

UsageIndustrial

MaterialPlastic

Crab Hoist - Heavy Duty Capacity 1Ton to 100 Tons | Effective Lifting Solution for Heavy Loads

Product DescriptionWe offer a quality range of Crab Hoist which is manufactured using quality raw material. Our range of Crab Hoist is highly effective and is widely used for shifting and lifting of heavy weight load. These Crab Hoists are totally cost effective and are supplied as per the various specifications provi

Arco Industrial Products

Vadodara

Trusted Seller

Trusted Seller14 Years

Premium Seller

Premium SellerPet Bottle Mould - Color: Gray

Price: 90000 INR/Piece

MOQ1 Piece/Pieces

UsageIndustrial

Product TypePlastic Bottle Mould

ColorGray

Shaping ModePlastic Extrusion Mould

MaterialOther, Mild Steel

Aastha Enterprises

Ghaziabad

Trusted Seller

Trusted Seller3 Years

Super Seller

Super SellerConcrete Chair Mould - Size: Standard

Price Trend: 200.00 - 250.00 INR/Piece

MOQ100 Piece/Pieces

UsageIndustrial

Product TypeConcrete Chair Mould

SizeStandard

MaterialOther, Concrete

Royal Tile Machines

New Delhi

Trusted Seller

Trusted Seller15 Years

Super Seller

Super SellerConcrete Block Mould

Price: 18000 INR/Set

MOQ1 Set/Sets

Supply Ability50 Per Month

Delivery Time7 Days

Solid Bronze Liners

Price: 1180 INR/Kilograms

MOQ10 Kilograms/Kilograms

UsageIndustrial

SizeStandard

ColorSilver

Product TypeSolid Bronze Liners

MaterialMetal

Kamaldeep Metal Works Pvt Ltd

New Delhi

Trusted Seller

Trusted Seller15 Years

Premium Seller

Premium SellerSemi Automatic Die Mould

Product DescriptionBrand : Nidhi Poly Plast\015\012Grade : Semi Automatic\015\012Material Grade : P20-EN31\015\012Mold Precision : As Per Requirement\015\012Runner : As Per Design\015\012Country of Origin : Made in India

White Silicon Mold Candle Bubble 15 Cavity

Price: 42000.0 INR/Piece

MOQ100 Piece/Pieces

Life SpanLong Working Life

UsageMaking Candle

ColorWhite

Product TypeSilicon Mold Candle Bubble 15 Cavity

Mold BaseSilicon

Cavity15

Art Vatika Institute

Faridabad

Trusted Seller

Trusted Seller2 Years

Premium Seller

Premium SellerLatest From Moulds

Ready To Ship Moulds

What is mould?

Introduction

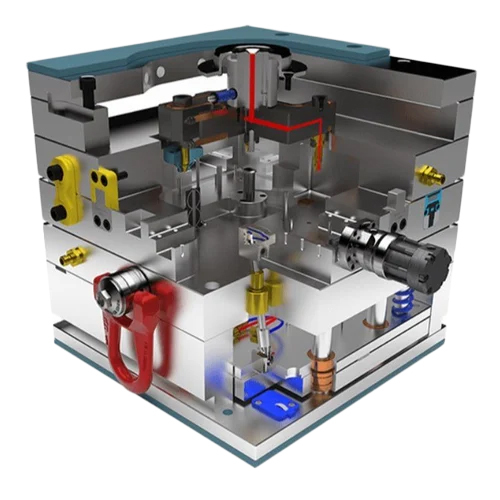

A mold is a tool used in manufacturing that is designed to create objects of a specific design and dimensions. When producing goods on an industrial scale, metal and non-metal materials are often shaped under pressure using a press and specialized tools attached to the press. Molds are a general term for a class of specialized instruments used for casting.

A mold is a typical piece of equipment in today's factories. Under high pressure, a malleable material like plastic, glass, metal, or ceramic raw material is forced into a hollowed-out block. Within the confines of the mold, the material sets, becoming the form of the final product. Injection molds, metal-plastic forming molds, and casting molds are just a few examples of the many different types of molds that exist.

Moulds: Design & Sizes

1. Oversize Design

Mould dimensions must account for the considerable shrinkage of MIM parts in the process steps after injection molding, namely binder removal and, more importantly, sintering. To empirically determine the shrinkage, we use the dimensions of the mold cavity to calculate the linear shrinkage of a 26-30 mm long by 4-6 mm broad rectangular bar.

Most of the time, the percentage of reduction may be calculated simply by multiplying the value by 100. The tool cavity extension factor Z accounts for material shrinkage when calculating the final component size L. Z = (mold dimension L0) / (final component size L).

2. Tire Mould design

To create a tire mould, it's necessary to first calculate the tire's inflated measurements. Preliminary plyline and mold dimensions are calculated using the inflated tire and the tire's growth characteristics. The tread, shoulder, sidewall, and bead contours can be determined when the mold boundary measurements, plyline position, and tread width and depth are all set.

3. Molded in-insert

Depending on the shape, number, and purpose of the insert will determine the best way to secure it. As a whole, molded-in inserts can be broken down into two categories.

When the dimensional accuracy of a molded section is inadequate, or when the wall thickness or mold dimensions make rotational molding impracticable, plastic inserts are utilized.

Tank access is a classic case in point because of the need for a bung or threaded spout to match with either metal or main plastic fitting. Pipe fittings like elbows, tees, and Ys are another example of applications where the interior dimension of the molded item must be accurate.

| Size | 18.9inch. x 29.6 inch. X 8inch. |

| Volume | 59cu.inch. |

| Depth | 4inch from parting line Up to 8 inch. If parting line can pass through the middle of the part |

| Projected Mould Area | 175 sq. in. |

Types of Moulds

1. Two/Three Plate

With three-plate Moulds, you may place the injection point wherever you like on the tool, even though it is still a cold runner tool because of the third plate in the runner system. In most cases, this is less expensive than installing a hot runner system, although automated processes can be complicated by the big, cumbersome runners used in these molds.

2. Insulated Runner Moulds

Insulated runner tools are similar to conventional cold runner molds, but they employ cartridge heaters or other means of heating to create an insulating ""cull"" of molten resin around the mold's perimeter.

Compared to employing a hot runner, which necessitates the purchase of a temperature controller, this method is more cost-effective. In some cases, such as when working with more demanding industrial grade resins, insulated runners are ineffective.

3. Cold Runner Molds

By using sprues and runners to gate into the component, classical tooling is exemplified by cold runner molds. This is the simplest version, however it can lead to more wasted materials and longer startup and shutdown times.

While the physical characteristics of the resin may be compromised, a certain amount of scrap may be reground and processed for future use, depending on the application.

If you're working with high-end, expensive materials like engineering or medical grade resins, or if regrind won't work for your application, a hot runner mold could be the way to go.

4. Hot Runner Molds

Hot runner tools employ a temperature-controlled manifold to drastically cut down on or do away with runner scrap altogether during the cycle. Both external and internal injection locations can be used.

Because the sprue or runner system is generally the deciding factor on the mold cycle, this can considerably improve cycle times. Getting rid of the runner also helps prevent the unnecessary waste of valuable resources.

A temperature controller, scaled to fit the manifold in the mold, is needed to run hot runner molds in a press. While hot runner tools have more extensive mold maintenance needs, the initial investment is usually recouped in reduced production time and material costs.

5. Unscrewing Moulds

The most frequent technique for making threaded holes inside a plastic component is to use molds that unscrew. Hydraulic motors, electric, or Rack-and-pinion are used for the automatic rotation of the threaded features in these molds, which are then used to extract the undercut features from the mold.

The thread extraction process is a continuous operation that is linked to the pressing cycle, allowing for the extraction of both internal and external threads. With multi-shot / multi-component tooling, a designer can simultaneously apply two or more distinctly different materials to a single part throughout the manufacturing process.

Materials might vary for a number of reasons, including their physical qualities or even their aesthetic appeal. These molds typically incorporate several manifolds into a single die. In addition to accommodating color variants throughout an entire product line, multi-shot tooling can be an elegant solution for complex items

The use of multi-shot tooling necessitates the use of specialized presses and molds. Possible future requirements include a rotary mold, several machine nozzles, and hot runner systems.

Manufacturers may not currently carry any multi-shot molding presses, but designers have a great deal of background working with complex machinery of this type.

6. Family Moulds

Unlike single-cavity molds, which can only produce one type of part, family molds can produce multiple variations from a single mold base. All the pieces can be made at once, or individual molds can be made for certain mold cavities with the use of shutoffs.

If you want to run all of the components at once, it's better if they have the same dimensions, shape, resin, and expected volume for the best molding results. Piece separation could be an automated process that occurs during or after production.

Using a family mold can help you save money and provide you more options if you're making low quantities.

7. Low and High Cavitations mold

Because of their limited capacity, single-cavity molds can only mass-produce a single product every cycle. Considering the minimal setup costs, they are a viable option for low-volume production runs. As an added bonus, their turnaround time is quicker. The downside is an increase in the per-part cost of molding production.

Molds with several cavities can increase output. More parts can be manufactured in the same amount of time, which means higher capacity and reduced component part costs.

How is mould formed?

For each product, a mold designer is responsible for conceptualizing and sketching the mold's internal structure to meet the product's functional specifications (part). The mold will then be made by experienced employees using a variety of mechanical methods to replicate the design. After that, the mold is put together and tested until it can create quality goods.

- Mold design: The viability of using a mold to manufacture the required items is first investigated. After that, the mold diagram is created and checked for errors.

- Mold Processing: A machine tool is used to cut the mold prototype into the specified form.

- Mold testing: The assembly of the mold and mold base is followed by testing and fine-tuning.

Because mold shapes can be somewhat complicated, and because some products have stringent demands for structural strength, stiffness, surface hardness, surface roughness, and machining precision, mold fabrication necessitates sophisticated machinery.

Conclusion

Hope you have got the need of industrial mould and molding process. In most cases, the molding equipment uses an automatic, self-gating tool to maintain efficiency and continuous production with a minimum of human intervention. In injection molding, a substance that is either liquid or melted is injected into a casting, sometimes called a mold, where it takes on the shape of the casting. In most cases, molds will have a male and female half, and the molten material will be injected into the space between the two halves.

FAQs: Moulds

Q. How is mould made?

Ans. Steel or aluminum is typically used to construct moulds, and then they undergo a precise machining process to achieve the desired details.

Q. What is a mould used for?

Ans. A mould is a tool used in manufacturing that is designed to replicate an object exactly. Industrial production molds used in injection molding, shaping, melting, extrusion, die casting, blow molding, forging, and more.

Q. What is the purpose of mould?

Ans. Moulds are the "mother" of industrial production because they are the essential building block of the manufacturing process. The mould is one of the most extensively utilized pieces of process equipment in today's industrial production because of its high quality, high yield, material savings, and low cost.

Q. What is the difference between mold and mould?

The word “Mold” is frequently spelled in American English, on the other side, the word “Mould” is spelled in British English. But both are the same.

Manufacturers & Suppliers of Moulds

Company Name | Member Since |

|---|---|

Everest Composites Pvt. Ltd. Vadodara, India | 18 Years |

Amey Shredtech Private Limited Thane, India | 18 Years |

Drishti Polymers Ahmedabad, India | 18 Years |

Royal Tile Machines New Delhi, India | 15 Years |

Kamaldeep Metal Works Pvt Ltd New Delhi, India | 15 Years |

Balaji Construction Machinery Rajkot, India | 14 Years |

Arco Industrial Products Vadodara, India | 14 Years |

Shanghai Fude Machinery Manufacturing Co., Ltd. Shanghai, China | 13 Years |

Laxmi Engineering Works Ahmedabad, India | 11 Years |

Kp Rubber & Polymer Vadodara, India | 10 Years |

Popular Products