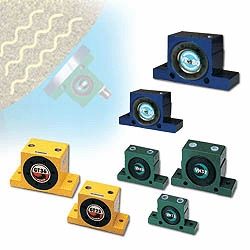

P { margin-bottom: 0.21cm; }With the help of a dedicated workforce, we are able to provide the clients with Pneumatic Vibrators. Made of high quality raw material that is supposed to be the best in the market, these products provide accurate and effective performance. Longer service life, low maintenance, resistance against corrosion and smooth operation are some of the main features of these products. Pneumatic Vibrators can be availed from us in different specifications as per the requirements of the clients. Other details:The casting and vibrating station with the vibrating tables generally are link of automated systems for producing prefabricated concrete handmades, such as segments for tunnels, ballast, gratings, etc. They are thus manufactured on request. The station consists of a stiff metal structure, elastically suspended and provided with electric or pneumatic vibrators. The vibrating station can rise and lower to receive the moulds, and it is provided with clamp levers to firmly secure it to the structure. On the other hand, tables are usually fixed, insulated from the support by springs and provided with mould locking members (on request). The moulds thus secured is subject to the vibrations generated by the vibrators for the entire duration of the concrete casting, so as to obtain a perfect filling and excellent surface finishing. Once the operation has been carried out, the mould is freed from the clamping levers to continue the production cycle, while another mould is delivered at the station. The vibrating station is custom-made for the system, and is supplied with electric and hydraulic system, programmed to operate in continuous cycle.