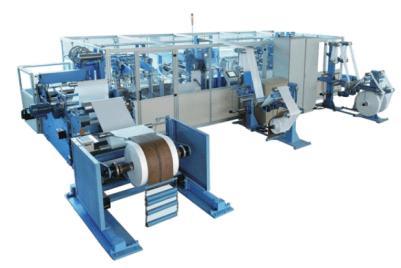

Pp Cement Bags Making Machine

Price:

Get Latest Price

In Stock

Product Overview

Key Features

2. Each line consists of:

1 set UNWINDING STATION

consisting of:

automatic control for guiding the fabric length with transversely movable unwinding stand, tension controller (correction distance < 100 mm)

roll monitoring system: alarm is given before the fabric roll is empty

2 winding shafts with pneumatic expansion chucks for a core diameter of 108mm (76 mm)

1 set PERFORATION SYSTEM

for providing a pin perforation in the tubular fabric to achieve better air permeability of the AD*STAR. sack. Perforation is effected over the complete surface of the sack.

1 set CROSS-CUTTING UNIT

for cutting the fabric to the preset length and consisting of:

intermittent traction system with servomotor

print mark reading device for printed tubular fabric

pneumatically operated knife including brake valves in the end positions

1 set INTERMITTENT FEED SECTION WITH PIN TRANSPORT

is the zone where the fabric length is cut. Consequently, the fabric is constantly decelerated and accelerated. The variations in speed are compensated by the compensator. The intermittent feed section consists of:

intermittent pin transport unit

Servo-drive with self-referencing function, thus ensuring a precise sack transfer

manually adjustable (depending on the sack dimension) bottom opening station

transfer station to the continuous transport section

1 set CONTINUOUS FEED SECTION

is the zone where the sack is transported at a constant speed and without pins to the different folding devices and welding stations. The continuous feed section consists of:

bottom closing by means of adjusting spindles

belt system for the transport of the sacks via an acceleration belt from the

main machine to the stacking unit

1 set MANUALLY ADJUSTABLE BOTTOM CENTER DISTANCE

for sack length adjustment

1 set VALVE UNIT

The valve patch, which has been cut from flat fabric, is applied onto the sack and welded by means of hot air. The valve unit consists of:

unwinding station with band brake, monitoring system for fabric end and

automatic control for guiding the fabric length

pneumatic expansion chuck

traction unit with separate servo-drive for the infinitely variable adjustment of the patch length

cutting unit for the valve patches, adjustment of the knifes with a special designed gauge is from outside possible.

hot air welding device

1 set BOTTOM PATCH DEVICES

The bottom patches, which have been cut from flat fabric, are applied onto the closed sack bottoms and welded by means of hot air. The bottom patch devices consist of:

unwinding station with band brake, monitoring system for fabric end and automatic control for guiding the fabric length

pneumatic expansion chuck

traction unit with separate servo-drive for the infinitely variable adjustment of the patch length during the operation

print mark reading device for printed bottom patches

cutting unit for the bottom patches, adjustment of the knifes with a specially designed gauge is from outside possible.

hot air welding device

1 set STACKING UNIT

constructed as a conveyor belt with package separation for an individually adjustable sack number per package

1 set MAIN DRIVE

consisting of:

position-controlled servomotors with transport system without pins

Duplex chain drive

control elements

drive connections to the other drive units by means of a software coupling

1 set ELECTRICAL INSTALLATION

central power distribution for drive, heating and control systems

control cabinet, completely installed and checked when connected to the line

optimized energy distribution and protection of the line components

modular machine structure for add-on and retrofit purposes

highly advanced safety and monitoring equipment with checking system

separate bus system for the drive system and the control level, including a clearly structured diagnosis system and an integrated software temperature control

control cabinet cooling by circulating air, for unlimited ambient temperatures

Company Details

Focusing on a customer-centric approach, CHINA TIANFENG INTERNATIONAL PLASTIC MACHINERY CO. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Machineries in bulk from CHINA TIANFENG INTERNATIONAL PLASTIC MACHINERY CO. LTD. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Distributor, Supplier

Employee Count

400

Establishment

1970

Working Days

Monday To Sunday

Related Products

Explore Related Categories

Seller Details

Hefei, Anhui Province

General Manager

Mr. Jerry Ge

Address

Shuangfeng Industrial Zone, Hefei, Anhui Province, 231131, China

cement bag making machine in Hefei

Report incorrect details