Pu Safety Shoe Making Machine - Stainless Steel, 6000x8000x2500 Mm | Automatic, Eco-friendly, Low Energy Consumption, Plc Control, High Efficiency, Lifetime Warranty

Price Trend: 20000.00 - 80000.00 USD

Get Latest Price

Minimum Order Quantity :

1

Product Specifications

| Product Type | pu shoe machine |

| General Use | this equipment can produce all types of pu shoes, like soles, insole, outsole, safety shoes, slippers, sandals, ect. |

| Material | Stainless Steel |

| Weight (kg) | 5000 Kilograms (kg) |

| Computerized | Yes |

| Automatic | Yes |

| Control System | PLC Control |

| Drive Type | Other |

| Heating Power | 34 Kilowatt (kW) |

| Voltage | 220/380 Watt (w) |

| Power | 220/380 Watt (w) |

| Dimension (L*W*H) | 6000*8000*2500 Millimeter (mm) |

| Color | green |

| Warranty | life-time |

| Feature | High Efficiency, High Performance, Low Noise, Compact Structure, Lower Energy Consumption, ECO Friendly |

| FOB Port | guangzhou, china |

| Payment Terms | Western Union, Telegraphic Transfer (T/T) |

| Supply Ability | 10 Per Month |

| Delivery Time | 30 to 40 Days |

| Sample Available | Yes |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | plastic film or discussed |

| Main Domestic Market | All India |

| Certifications | ISO |

Product Overview

Key Features

Product Application

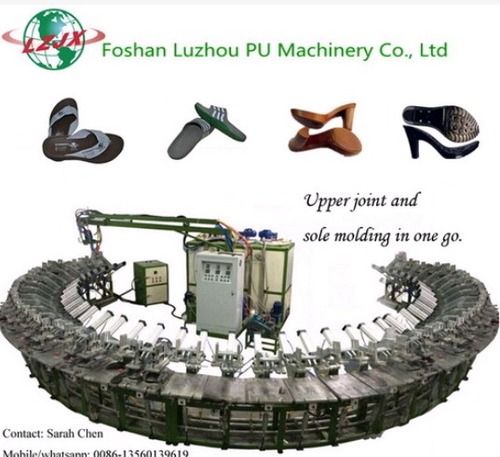

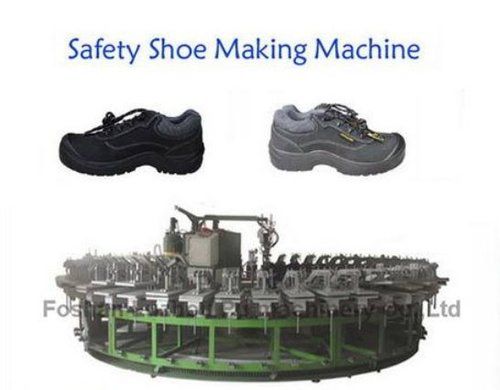

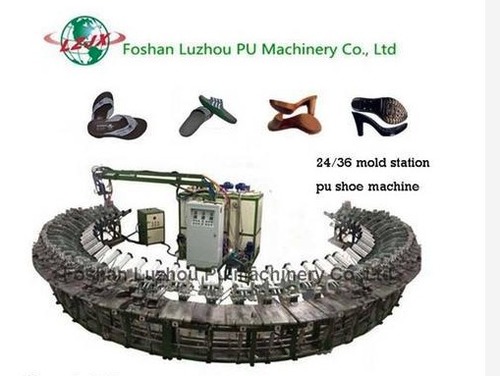

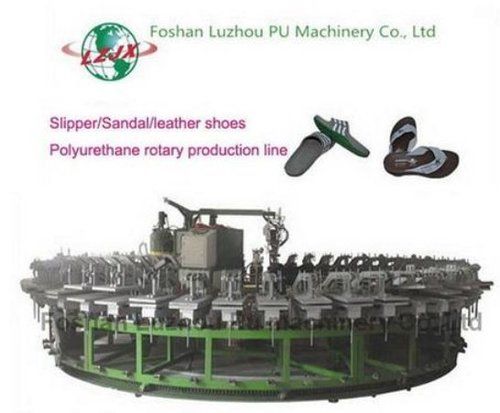

This equipment is used to produce polyurethane insoles, outsoles, high heels, leather shoes, casual shoes, safety shoes, travel shoes,slippers, sandals, flip flops and other all kinds of polyurethane shoes.

Product Component

This equipment includes one three components low pressure pu foam machine and one automatic banana-type production line. According to the client's production capacity, the production line has 24, 36, 60, 80,100,120 or other mold stations for choose.

Why choose it:

1. Most of the components are imported, like the metering pump and electrical components, greatly enhancing equipment running reliability and service life;

2. The moulds can be opened and closed automatically by the pneumatic system which can save the labor cost and around 2~4 people are required for the production only.

3. The molds are heated by circulating water heating system, it can save 3/2 electricity compared with the traditional manual machine, it also makes the temperature of the molds stabler.

4. the injection can be or can not be robotic control, which is customized for the client.

Company Details

Business Type

Exporter, Manufacturer, Supplier, Wholesaler, Retailer, Fabricator, Producer

Employee Count

50

Establishment

2013

Working Days

Monday To Sunday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

Seller Details

Foshan, Guangdong

Ms. Sarah Chen

Address

No.2, Jianhe hedong, yanbu Nanhai, Foshan, Guangdong, 528247, China

shoe making machine in Foshan

Report incorrect details