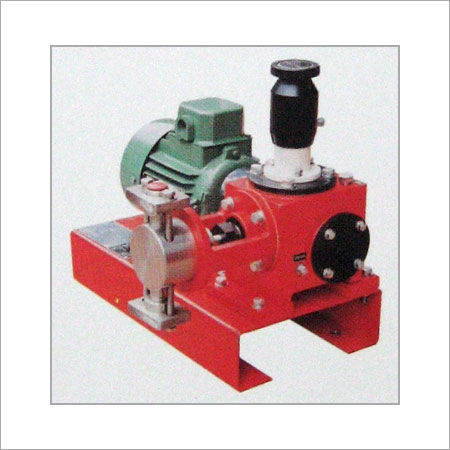

Pump Process Equipments

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Dimensions | Variable |

| Max Thickness | 50Mm |

| Max Weight | 100Tons |

| Manufacturing Bay | 16Mx85Mx10M |

| Design Codes | Asme |

| Testing | Hydrostatic |

| Features | Easy Installation, Minimum Maintenance, High Durability, Precise Engineering, Various Testing, Durable Material, Long Lifespan, Cost Effective |

| Payment Terms | Cash Against Delivery (CAD), Cash in Advance (CID) |

| Supply Ability | Customized |

| Main Export Market(s) | Central America, Eastern Europe, Middle East |

| Certifications | ISO 14001:2004 ,9001:2008 |

Product Overview

Key Features

Company Details

Focusing on a customer-centric approach, POSITIVE METERING PUMPS (I) PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Processing Machines & Equipment in bulk from POSITIVE METERING PUMPS (I) PVT. LTD. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

110

Establishment

1998

Working Days

Monday To Sunday

GST NO

27AACCP0388D1ZK

Certification

ISO 9001: 2000

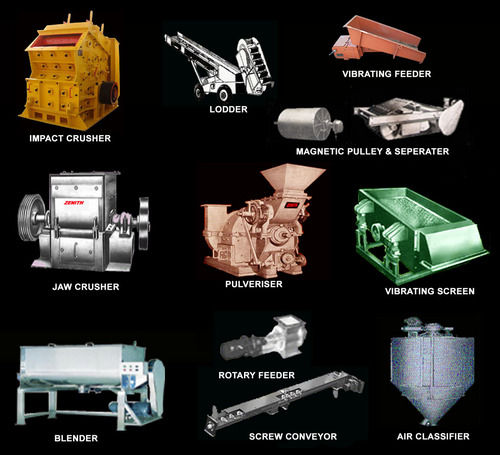

Related Products

Explore Related Categories

Seller Details

GST - 27AACCP0388D1ZK

Nashik, Maharashtra

Manager Business Development

Ms. Smita M.

Address

Plot No. - M-8, M. I. D. C., Ambad MIDC, Nashik, Maharashtra, 422010, India

process pumps in Nashik

Report incorrect details