Pvc Wpc Door Panel Machine - 300 Kg Capacity, 75kw Power, Automatic Grade Semi-automatic, Direct Drive, Frequency Speed Control, Extrusion Technology

Price: 80000 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Type | Extrusion |

| Material | PVC WPC |

| Capacity | 300 Kilogram(Kg) |

| Computerized | Yes |

| Automatic Grade | Semi-Automatic |

| Control System | Frequency Speed Control |

| Drive Type | Direct |

| Screw Diameter | 80/156 Millimeter (mm) |

| Power | 75kw |

| FOB Port | Qingdao |

| Payment Terms | Cash on Delivery (COD), Letter of Credit (L/C), Paypal, Western Union, Letter of Credit at Sight (Sight L/C), Cash Against Delivery (CAD), Cash Advance (CA), Telegraphic Transfer (T/T), Cash in Advance (CID) |

| Supply Ability | 10 Per Month |

| Delivery Time | 60 Days |

| Main Export Market(s) | Australia, South America, Western Europe, Middle East, Central America, Africa, Asia, Eastern Europe, North America |

| Certifications | CE certificated |

Product Overview

Key Features

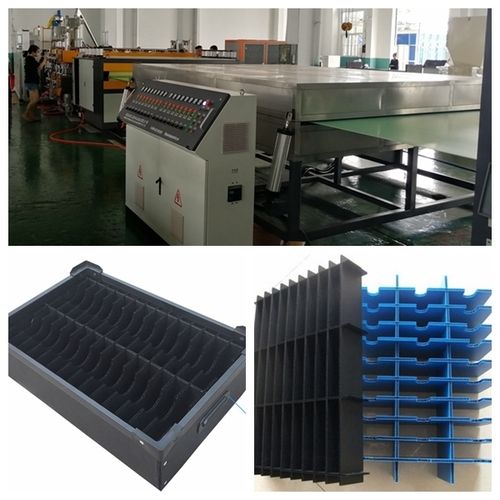

This production line is applicable to the continuous extruding of WPC/PVC door panel, clapboard 'elbow board. Proper double screw extruder, specially used for extruding wood plastic products, should be chosen in accordance with the panel section, application, and product specific gravity. Also the corresponding auxiliary machines such as vacuum calibrating platform, hauling off machine, cutting off machine, material reversing platform,etc. are equipped. Products of diversified specification can be produced with different dies. PVC WPC Door Board Production Line is adopted specially designed HGMS80/156, HGMS92/188 conical twin screw extruder. It adopts imported ABB and Siemens speed frequency converter. It chooses imported RKC and Omron temperature controller. It possesses the features of easy and reliable operation. The production line consists of conical twin screw extruder, moulds for door boards, forming moulds, calibrating cooling stage, caterpillar haul-off, transverse cutter and tilt stacker.

It can be used either inner and outer door board, partition, window sill etc. or PVC and PVC+ wood extruding foaming craft. The final products produced by the PVC door board extrusion line centralizes the characters of plastic and wood. It not only has special appearance effect, but also overcomes the shortage of wood. It has good processability as wood, and the proportion can be controlled in 0.6-0.9kg/mA .

Company Details

Qingdao Tongsan Plastic Machinery Co., LTD. is a professional plastic extrusion machines manufacturer which stands by the Jiaozhou Bay. Converged with the national first-class scientific talests, our company is engaged in the study of new- type plastic machines and the conversion of international high-and –new technology. Cooperating with scientific research instifutions and institutions of higher education , we are converting the newest scientific payoffs at top speed. We will supply you the high-performance and high-tech plastic machines, Hollow sheet machine, Corrugated pipe machine, PVC and WPC foam board making machine Quality is Tongsan’s style ,prestige is Tongsan’s character, and innovation is Tongsan’s eternal pursuit .Welcome domestic and overeas customers to visit our company with full passion. We are willing to work with you to unite as one with effort to create a bright future.

Business Type

Exporter, Manufacturer, Service Provider, Supplier, Fabricator

Employee Count

120

Establishment

1997

Working Days

Monday To Sunday

Related Products

Explore Related Categories

Seller Details

Qingdao, Shandong

Mr. Rosy Qin

Address

The West End And South Side Of Yangzhou Road, Jiaozhou, Qingdao, Shandong, 266300, China

plastic extrusion machines in Qingdao

Report incorrect details