Mining, Exploration & Drilling Machinery

(8700 products)Action Construction Equipment Ltd.

Faridabad

Super Bonanza

Super Bonanza10 Years

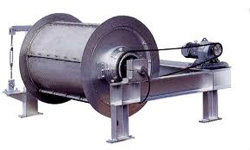

High Gradient Drum Separators

Product DescriptionWe leading manufacturer supplier, exporter of High Gradient Drum Separator to our most valued customers. These are widely used in the following applications: \015\012* Foundries\015\012* Blast furnace and BOF slag\015\012* Open hearth slag\015\012* Dry magnetite ore cobbing\015\012* Auto fragmentiz

Magna Tronix

Chennai

4 Years

Jaw Crushers - High-Performance Crushing Machine , Durable Design with Customizable Features

Product DescriptionWe are the leading fabricator, exporter and supplier of qualitative Jaw Crushers in Navi Mumbai, Maharashtra, India. The offered product is catered to numerous application areas in construction industry. Designed with our cutting edge technology these jaw crushers are extensively used for crushing

Siddharth Engineering Co.

Navi Mumbai

14 Years

Super Premium

Super PremiumGundrill Regrinding Machine - Automatic Grade: Automatic

Price: 2500000 INR/Unit

MOQ1 Unit/Units

ConditionNew

Spindle Speed3000 RPM

Dimension (L*W*H)500 x 700 x 1700 Millimeter (mm)

Product TypeRegrinding Machine

MaterialMetal

Automatic GradeAutomatic

Precihole Machine Tools Pvt. Ltd.

Bhiwandi

Super Bonanza

Super Bonanza9 Years

Moderate Machines (pvt.) Ltd.

Jaipur

14 Years

Geared Radial Drilling Machine - 40mm Drilling Capacity in Steel, 250mm Spindle Travel, 2HP Motor | 8 Speed Range, Auto Arm Elevation, 1050mm Max Drilling Radius

Product DescriptionWe are Making, Exporting, Distributing and Supplying Geared Radial Drilling Machine in New Delhi, Delhi, India. Details as given below:-\015\012\015\012 Technical Specification: \015\012Specification:\011Size\015\012Drilling Cap. in Solid:\011 \015\012In Steel Having 600Mpa Tensile Strength:\0114

Didac International

New Delhi

10 Years

Vmc 3 Axis Drill Machine, Usage/Application: MILLING

Product DescriptionVmc 3 Axis Drill Machine

Tirupati Cnc Products

Rajkot

Super Bonanza

Super Bonanza6 Years

Lal's Exporters (india) Private Limited

Patna

2 Years

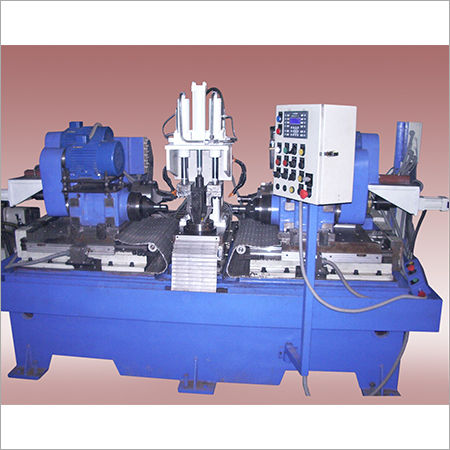

Cnc Boring & Grooving Spm - Automatic Grade: Automatic

Price: 3000000.00 INR/Unit

MOQ1 Unit/Units

ConditionNew

ColorBlue

MaterialMild Steel

ComputerizedNo

Automatic GradeAutomatic

CNC Or NotCNC

Patson Machines Pvt. Ltd.

Pune

16 Years

Carton Tapping Machine - Accuracy: 100 %

Price: 95500 INR/Unit

MOQ1 Unit/Units

Dimension (L*W*H)1250*650*1040-1380 Millimeter (mm)

TypeCarton Taping Machine

Power220 Volt (v)

Voltage220 Volt (v)

Sealing Speed20meter/min.

ApplicationFor Carton Packing

Smart Packaging System

Indore

10 Years

Hydraulic Press Brake Machine - Material: Iron

Price: 880000.0 INR/Unit

MOQ1 Unit/Units

Product TypeOther, Hydraulic Press Brake Machine

MaterialIron

Power SourceElectricity

Operating TypeSemi Automatic

Power440 V Volt (v)

Voltage240 Volt (v)

Emtex Machinery Private Limited

New Delhi

11 Years

Semi-Automatic Engineering Reversible Ratchet

Price: 1200000 INR/Piece

MOQ1 Piece/Pieces

ComputerizedYes

Automatic GradeSemi-Automatic

Inder Industries

Jalandhar

11 Years

Automatic EDM Drilling Machine

Payment TermsCash Against Delivery (CAD), Others, Cheque

Main Domestic MarketAll India

Berlin Machineries Private Limited

Pune

5 Years

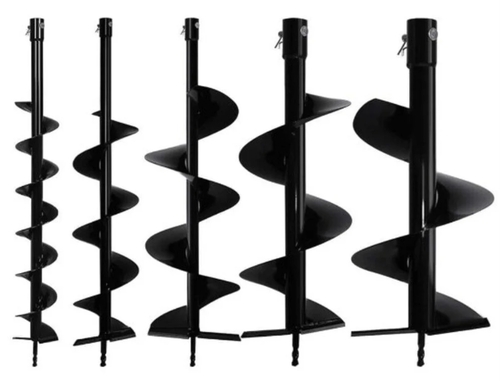

V-Power 224 Cc Earth Auger

Price: 38500 INR/Piece

MOQ1 Piece/Pieces

Table Size4 to 20 inches

Power7.5 Horsepower (HP)

Weight (kg)15 Metric Ton

Vinspire Agrotech (i) Private Limited

Ahmedabad

8 Years

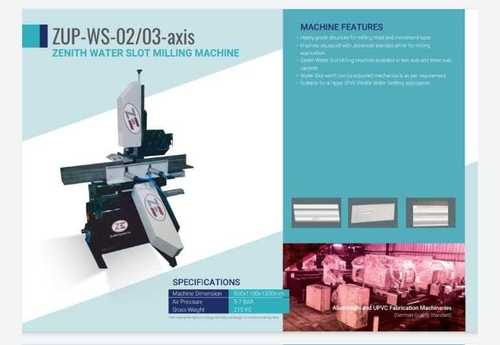

Super Premium

Super PremiumSemi-Automatic Upvc Plane Water Slot Drill Machine

Price Trend: 100000.00 - 300000.00 INR/Unit

MOQ1 Piece/Pieces

ConditionNew

Product TypeUPVC Plane Water Slot Drill Machine

MaterialMild Steel

ComputerizedNo

Automatic GradeSemi-Automatic

Voltage240-380 Volt (v)

Zenith Engineering And Equipments Private Limited

Vadodara

11 Years

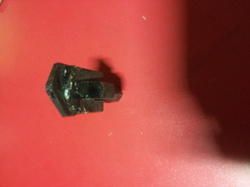

CB Type Drill - Premium Quality Steel, New Condition | Durable, Longer Service Life, Easy Handling, Sleek Black Finish

Price: 10 INR/Piece

MOQ2000 Piece/Pieces

ConditionNew

Product TypeDrill

ColorBlack

Vinay Engineering Company

Vasai

8 Years

Bosch Breaker Drilling Machine - Automatic Grade: Semi-Automatic

Price: 28500 INR/Unit

MOQ1 Unit/Units

ConditionNew

Automatic GradeSemi-Automatic

Control SystemManual

Voltage220-240 Volt (v)

Power1500 Watt (w)

Power SourceElectric

M K International

Mumbai

1 Years

CORE DRILLING MACHINE

Product DescriptionTHE MACHINE IS PROVIDED WITH HAND OPERATED RAPID SCREW FEED THROUGH A LEVER DRIVE WITH BUILT IN BALL BEARING. THE DRILL SPINDLE IS FLOATING ON TAPERED ROLLER BEARINGS. WATER SWIVEL IS TOTALLY ENCLOSED AND MOUNTED ON THE DRILL SPINDLE. THE DRILL DRIVE SHAFT IS MOUNTED ON TWO BALL BEARINGS IN THE DRIL

Eie Instruments Private Limited

Ahmedabad

15 Years

Klr Dthr-600 Dth Cum Rotary Drill Rig - Automatic Grade: Semi-Automatic

Price: 10500000 INR/Unit

MOQ10 Unit/Units

MaterialStainless Steel

ComputerizedNo

Automatic GradeSemi-Automatic

CNC Or NotNormal

Power SourceHydraulic

Klr Industries Limited

Hyderabad

3 Years

Semi-Automatic Hydraulic Piling Rig Machine

Price: 800000 INR/Unit

MOQ10 Unit/Units

MaterialStainless Steel

ComputerizedNo

Automatic GradeSemi-Automatic

CNC Or NotNormal

Power SourceElectricity

Shivam Construction Company And Earth Movers

Rohtak

3 Years

Semi-Automatic Zsk2104 Gun Drilling Machine

MOQ1 Unit/Units

Product TypeGun Drill Machine

MaterialSS

ComputerizedNo

Automatic GradeSemi-Automatic

CNC Or NotCNC

ColorSilver, Black

Dezhou Hongxin Machine Tool Co., Ltd.

Dezhou

2 Years

Universal Electric Tapping Machine

ConditionNew

Product TypeUniversal Electric Tapping Machine

ComputerizedNo

Automatic GradeSemi-Automatic

Voltage220-315 Volt (v)

Power SourceElectric

Haron Cutting Machines Co., Ltd

Zibo

3 Years

Line Boring Machine - Mild Steel, 240V Electric Power Source | Automatic Operation in Blue Finish

Price: 350000 INR/Piece

MOQ1 Piece/Pieces

ColorBlue

ConditionNew

Product TypeLine Boring Machine

MaterialMild Steel

Automatic GradeAutomatic

Voltage240 Volt (v)

Prateek International

Faridabad

7 Years

Ms Industrial Impact Crushers

Price: 225000.00 INR/Unit

MOQ1 Unit/Units

UsageIndustrial

Equipment TypeIndustrial Impact Crushers

ConditionNew

MaterialMS

Power SourceElectric

Destiny Solution And Engineers

Ahmedabad

6 Years

Radial Drilling Machine - MT-40/1000 DC, 40 mm Drilling Capacity, 8 Spindle Speeds Range 90 to 1000 RPM

Product DescriptionWe offer the most modern and advanced radial drilling machine. It is built to meet the most exacting requirements of engineering and allied trade for various operations such as drilling, tapping, lapping and boring materials like cast iron steel, plastics, etc. Its specifications and features are:\

Golden Machinex Corporation

Kolkata

6 Years

Automatic Tdls Cd Drilling Machine

Price: /Unit

MOQ1 Unit/Units,

ConditionNew

Product TypeDrilling Machine

MaterialMetal`

ComputerizedYes

Automatic GradeAutomatic

Voltage220-320 Volt (v)

Scantech Laser Pvt. Ltd.

Navi Mumbai

13 Years

25 MM Radial Drill Machine - Stainless Steel, Semi-Automatic, Electric Power Source | Ideal for Wood, Metal, and Plastic Drilling

Price: 400000 INR/Unit

MOQ1 Unit/Units

ConditionNew

MaterialStainless Steel

ComputerizedNo

Automatic GradeSemi-Automatic

CNC Or NotNormal

Control SystemManual

Parmar Engineering

Pune

2 Years

OM KAILASH

Product Descriptionwe are the leading manufacturer of Sugarcane crusher we can supply to our client as per their requirement n their application. These quality finished crushers are available in a very competitive price. These high precision and tough crushers are of latest design, so as to provide maximum result wit

Patel Manufacturing Company

Upleta

14 Years

Latest From Mining, Exploration & Drilling Machinery

Diamond Core Drill

By:

Kou Sheng Feng Co. Ltd.

Double Toggle Jaw Crushers

By:

Arihant Industries

Milling Chuck

By:

Alpha Solutions

Explore More Cities

Ready To Ship Mining, Exploration & Drilling Machinery

Modern Mining, Drilling & Exploration Machinery: Applications

Introduction

Exploration and drilling would not be possible without this hefty Modern Mining, Drilling & Exploration Machinery. Heavy trucks, drills, and bulldozers make up the range; they're employed for hauling out rocks of varying hardness, processing ore, and reclaiming the land when the mine closes.

Coal, gold, and jewels are just a few of the many valuable resources that are mined from the soil. Mining technology has turned a new leaf in the face of modernization, allowing workers to face less risks in their daily work. Surface mining is the norm and the normative in the mining industry.

Tools like shovels, cranes and big rigs are used to move around large amounts of mineral and waste material. In addition, processing plants use huge and powerful machinery such as crushers, reactors, mills, roasters, and associated equipment to fortify the mineral-rich material and separate the necessary metals and compounds from the ore.

The use of cutting-edge technology is essential in the mining, exploration, and drilling processes.

- Trenchers

- Reactors

- Power Shovels

- Bulldozer

- Drills

- Excavators

- Mills

- Large Crushers

- Mining Trucks

- Scrapers

- Trams

- Roasters

What Are Mining, Drilling & Exploration Machinery?

It's a method that's put to use in the mining of minerals to

- Search for undiscovered mineral deposits

- Assess potential mining sites

- Increase the mine's ore reserves and materials by the third clause.

New mineral resources that can be extracted profitably either now or in the future can be located through exploration drilling. To find deposits of minerals or rocks that can be exploited to provide for societal resource needs, such as:

- Clay, rock, limestone, sulfur, salts, and fertilizer minerals are all examples of industrial raw materials.

- Metal extraction ores such as iron, copper, and zinc

- Diamonds, sapphires, and opals are all examples of gems.

- Coal, oil shale, and uranium are examples of solid fuels.

Over the past century, technological advancements in the mining industry have allowed for the creation of open pits with progressively greater depths.

Difference Between Mining & Drilling Machinery

1. Mining Machinery

Let's pretend there's coal a thousand feet underground. To get access to the coal below ground, we must first remove the matrix or overburden layer that sits atop the coal. Mining refers to this operation. Mining is the process of extracting solids from the earth, most commonly coal, metals, and other minerals.

The equipment and vehicles used in the Mining, Exploration & Drilling Machinery industry to excavate and transport the ground and the resources extracted from it, Overburden removal from surface mines involves digging, scooping debris into a loader, and transporting it elsewhere.

2. Drilling Machinery

Let's pretend hydrocarbons are hiding out in the underlying pore spaces of sandstone or limestone. To bring them back to the surface, we use drilling operations rather than mining. For example, high pressure allows liquids to be easily brought to the top in this situation (Due to overburden stress). Here, too, mining is possible, though it is not profitable for corporations. And so Drilling is the method of choice.

Machines are used for boring holes into the ground for many purposes, including prospecting, well sinking, extracting oil and gas, obtaining water and salt, and conducting scientific research. Holes must be drilled into rock for use with blasting charges in tunneling, mining, and other forms of excavation.

Drilling machines spin and hammer on the workpiece. The drill bit will vibrate and progress as soon as it retracts when set to impact or hammer mode. Since this is the case, the devices can quickly bore through any surface, including concrete. Using these power tools, you can easily cut channels in a wall and conceal unsightly wires and cables.

How Many Types of Mining, Drilling & Exploration Machinery?

Mining Machine types:

1. Large Mining Trucks

Heavy-duty trucks are required to transport goods around a mine site. Large mining trucks, also known as off-road trucks, are available with either a powerful mechanical drive or an electric drive, respectively. Extra-large tires allow these mining vehicles to carry big cargo over the rough terrain typically found around surface mines, making them a great alternative to standard trucks.

2. Hydraulic Mining Shovels

Hydraulic mining shovels are often built in a similar fashion. The cabs on these vehicles typically rotate on a base that is equipped with either tracks or wheels. The operator can reach materials all around the shovel because of its revolving design. The operator is able to manipulate the shovel, which is held by an articulated arm, from the safety of the cab.

3. Larger Dozers

Huge mining dozers make quick work of transporting materials from one area to another. In addition, these dozers may function on a wider variety of surfaces because of the option of using vehicles with wheels or tracks.

4. Electric Rope Shovels

Electric rope shovels employ a system of pulleys and ropes to manipulate the shovel at the end of the arm rather than hydraulics. These versions of electric-powered shovels are a significant improvement over their hydraulic counterparts in terms of both efficiency and durability.

5. Rotary Drill Rigs and Rock Drills

In order to lay charges for blasting open mines, rotary drill rigs produce holes in the rock or soil. There are two primary kinds of drills used in mining, and one of them is a rotary drill rig. Percussion drills, also called hammer drills, are another option.

Drilling Machine Types:

1. Micro-drill Press

The micro drill press is a high-precision machine with a fast spindle. The micro drill press is often quite compact and is limited in the size of the components it can work with. Benchtop versions of micro-drill presses are widely available.

2. Multiple Spindle Drilling Machine

A multispindle drill press is a popular name for a machine that has many drill bits. This multi-spindle drill press is designed for a specific purpose. The spindles are all simultaneously fed into the workpiece. If you have a lot of parts with lots of holes in close proximity, a machine like this will come in handy.

3. Gang Drilling Machines

The gang drill press, also known as a gang drilling machine, features many drill chucks situated above a single table. When multiple holes need to be drilled quickly and precisely, this sort of drill press is the way to go. The first bit can be used for spot drilling, for instance. It's possible to tap the drill with the second head.

4. Radial Arm Drill Press

The radial arm drill press is the workhorse of any machine shop that needs holes to be drilled. A radial drill press is a popular name for this machine. As opposed to bringing the workpiece to the tool, the radial arm drill press permits the spindle to be placed directly over the workpiece. In particular, for large, awkwardly positioned items, the radial drill press's architecture allows for a wide range of applications.

5. Upright Drill Press

Heavy-duty drilling is accomplished using the upright drill press (Figure 2), which often has a geared drive spindle head. In most cases, larger or heavier components necessitate the employment of a drilling machine of this size and weight.

Exploration Machine Types:

1. Deep Hole Exploration Machine

Connecting rods, barrels, Spindles, and certain pieces of oil-well exploration equipment are typical targets for this specialized type of exploration machine.

2. Pillar Drilling Machine

A pillar drill machine also called an upright drilling machine, is a high-tech tool for boring holes 20 mm to 40 mm in diameter into metal and wood. It reminds me of a bench drill. Nonetheless, it can drill deeper and more frequently than a standard bench drill.

3. Portable Exploration Tool

To drill holes up to 12 millimeters in diameter on any surface, a portable exploration machine can be utilized. Through wood, plastic, metal, and even concrete, it can bore a hole. Portable exploration machines are useful for a wide variety of jobs because of their portability and compact size.

FAQs: Modern Mining, Drilling & Exploration Machinery

Q. What is exploration drilling in mining?

Ans. Drilling into the ground is an integral part of mineral exploration because minerals are typically found deep down. Drilling is used to learning about the composition and structure of rocks, as well as the relationships between the rock layers at different depths.

Q. How does mining, drilling & exploration machinery work?

Ans. Up to 65% of the machine's weight can be worked to rotate the drill stem while a thrust is provided to it via a pulldown mechanism.

Q. What are the major manufacturers of mining, drilling & exploration machinery?

Ans. Here are the best manufacturers in India:

- Northern Pneumatic Tools

- Shivanta Engineering

- Generic

- Bosch

- Camel

- Black & Decker

Q. What is the future of mining, drilling & exploration machinery?

Ans. As the number of drilling and exploration machinery projects throughout the world rises, this market is expected to expand at a staggering rate over the next few decades. Due to its growing mineral demand, India has emerged as a promising new market for the world's leading mining industry providers.

Manufacturers & Suppliers of Mining, Exploration & Drilling Machinery

Company Name | Member Since |

|---|---|

Patson Machines Pvt. Ltd. Pune, India | 16 Years |

Eie Instruments Private Limited Ahmedabad, India | 15 Years |

Siddharth Engineering Co. Navi Mumbai, India | 14 Years |

Moderate Machines (Pvt.) Ltd. Jaipur, India | 14 Years |

Patel Manufacturing Company Upleta, India | 14 Years |

Scantech Laser Pvt. Ltd. Navi Mumbai, India | 13 Years |

Emtex Machinery Private Limited New Delhi, India | 11 Years |

Inder Industries Jalandhar, India | 11 Years |

Zenith Engineering And Equipments Private Limited Vadodara, India | 11 Years |

Action Construction Equipment Ltd. Faridabad, India | 10 Years |

Popular Products