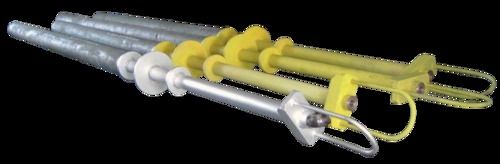

Refractory/monolithic Injection Lance

Price:

Get Latest Price

In Stock

Product Specifications

| Payment Terms | Cash on Delivery (COD), Cash Against Delivery (CAD), Cheque, Cash Advance (CA) |

| Sample Available | Yes |

| Sample Policy | Contact us for information regarding our sample policy |

| Main Domestic Market | All India |

Product Overview

Key Features

we customize refractory lance design keeping in mind the needs of various clients.

the top refractory monolithic lance technology integrates a variety of functions which expand the metallurgical and operational capabilities.

refractory lance, offered by us, is widely used in varied steel industries for strength and performance. composite constructions is available in thermally stable and slag resistant vibrocast refractory materials having high density, strength and structural integrity with divergent outlets.

we customize refractory lance design keeping in mind the needs of various clients.

the top refractory monolithic lance technology integrates a variety of functions which expand the metallurgical and operational capabilities.

following media can be blown:

a) oxygen for :

decarburization at high initial carbon levels

co post combustion

chemical heating of liquid steel by aluminothermic reaction

b) gaseous fuels (nitrogen, argon, oxygen, etc.) for :

refining/homogenisation of liquid steel

compensation of thermal loss

c) metallurgical powder (lime, alumina, synthetic slag, iron oxide) for :

desulfurization

decarburization

summary:

provides various additional functions

extended metallurgical degree of freedom

reduced temperature loss of steel

extended refractory lifetime

improved plant availability

improved sequence casting capability

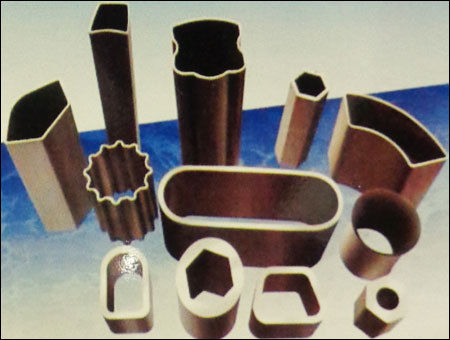

sizes available :

all international shapes & tailor made

following media can be blown:

a) oxygen for :

decarburization at high initial carbon levels

co post combustion

chemical heating of liquid steel by aluminothermic reaction

b) gaseous fuels (nitrogen, argon, oxygen, etc.) for :

refining/homogenisation of liquid steel

compensation of thermal loss

c) metallurgical powder (lime, alumina, synthetic slag, iron oxide) for :

desulfurization

decarburization

summary:

provides various additional functions

extended metallurgical degree of freedom

reduced temperature loss of steel

extended refractory lifetime

improved plant availability

improved sequence casting capability

sizes available :

all international shapes & tailor made

Company Details

Focusing on a customer-centric approach, Stomoma Infra Pvt. Ltd has a pan-India presence and caters to a huge consumer base throughout the country. Buy Pipes & Pipe Fittings in bulk from Stomoma Infra Pvt. Ltd at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Establishment

2010

Working Days

Monday To Sunday

GST NO

27AAOCS7867A1ZX

Related Products

Seller Details

GST - 27AAOCS7867A1ZX

Mumbai, Maharashtra

Director

Mr. Sanjay Aaggarwal

Address

Office no- F-301, Remi biz court, Shaha Industrial Area, Andheri west, Mumbai, Maharashtra, 400053, India

Pipes & Pipe Fittings in Mumbai

Report incorrect details