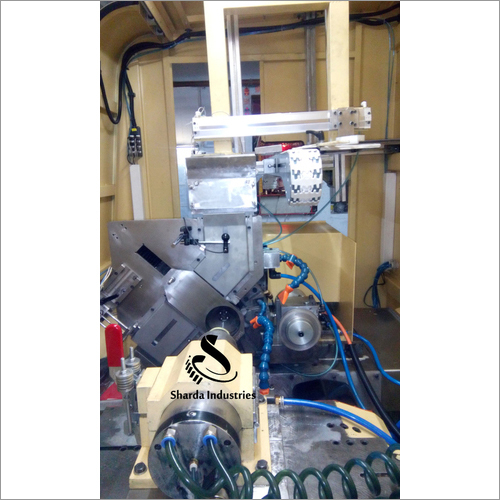

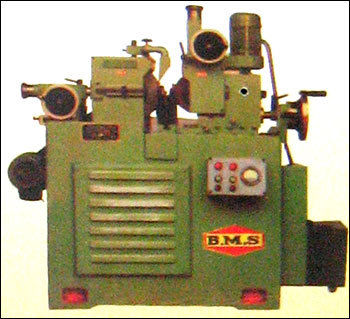

Retrofit Of Cylindrical Grinding Machines

Price:

Get Latest Price

In Stock

Product Specifications

| Main Export Market(s) | Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa |

Product Overview

Key Features

The scope of services ranges from overhauling and retrofit to retooling of grinding machines, i.e. the adaption of the machines to new parts and processes, for various applications such as gear shafts, crank- and camshafts, bearings grinding and aerospace applications.

Own grinding process experts and specifically trained mechanical engineers and programmers ensure a professional and trouble-free execution of the overhauling and modernization projects. From the first inspection and analysis of the actual machine condition to the operational hand-over of the rebuilt machine.

Overhauling

Replacement of all worn parts, substitute solutions for parts that are no longer available in the market.

Goal:

- Re-establishing the original productivity of the machine

- Extension of the machine service life

- Re-establishing accuracy

- Securing the availability of spare parts

Retrofit

Upgrading with new functions and/or new CNC

Goal:

- Increase of productivity and performance

- Upgrade to new grinding technologies

- Adaption of the machine to new IT structures

Rebuild/Retooling

Conversion of machines and complete manufacturing systems to fulfill new machining tasks.

Goal:

- Manufacturing of new parts/new part types

- Change of manufacturing processes and sequences

Spare Parts

Beside standard spare parts we offer our customers the replacement of original sub-assemblies or substitution of original spare parts for all well-known grinding machine brands.

Conception - Engineering - Documentation

We provide the full range of services from development of the concept throughout the realization including all mechanical, electrical and controls changes up to the preparation of new documentation or change of the existing documentation.

Concept development

- Own mechanical project engineering

- In-house software engineering

- In-house fluidics engineering

- Own grinding process application engineers

- Own documentation department

Company Details

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

600

Establishment

2011

Working Days

Monday To Sunday

Related Products

Explore Related Categories

Seller Details

Lebach, Saarland

Ms. Stephanie Schuppert

Address

Hans-Schardt-Str. 1, Lebach, Saarland, Germany

automatic grinding machine in Lebach

Report incorrect details