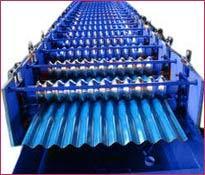

Roofing Sheet Roll Forming Machine - Max Sheet Width 350mm, Max Sheet Thickness 3mm Crca Strips, 14 Forming Stations, 16 Hp Power | Includes 5 Ton Decoiler, Double Punching Press, Semi-auto Control Panel, Hydro Cutting Unit

Price:

Get Latest Price

In Stock

Product Overview

Key Features

Maximum sheet width that can be formed 350mm

Maximum sheet thickness in CRCA Strips that can be formed 3 mm(M.S.)

Horizontal distance between shafts 400mm

Number of forming stations 14 nos.

Vertical station 12 nos.

Total HP for Line 16

Speed of the machine 4mt/minute

Size of machine 6300 x 1200 x 1000 mm

A) D coiler 5 ton cap.

B) Punching press 20 tone 2 nos.

C) Entry Gate with

D) Roll Forming Line with 14 station, 7 Gear Boxes & 10 H.P. electrical.

E) Control Panel semi auto

F) Cutting Unit (Hydro.)

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

7

Establishment

2011

Working Days

Monday To Sunday

GST NO

24AHOPJ9638G1ZY

Payment Mode

Cash Against Delivery (CAD)

Related Products

Explore Related Categories

Seller Details

GST - 24AHOPJ9638G1ZY

Rajkot, Gujarat

Proprietor

Mr Jaypal Sinh Jadeja

Address

Dholara Chokadi, Near Leo Packers, Gondal Road, Chokadi, Rajkot, Gujarat, 360002, India

sheet roll forming machine in Rajkot

Report incorrect details