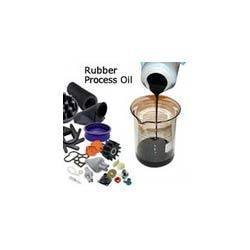

Rubber Oils EXCEL RUBBEROIL 245 is a paraffinic type, medium bodied rubber processing oil formulated from highly refined, solvent extracted base stock of low sulphur content. This conforms to ASTM 104 type. EXCEL RUBBEROIL 541 is a naphthenic type rubber processing oil conforming ASTM 103 type. It is formulated from carefully selected napthenic base stock. These oils possess excellent thermal, oxidation and colour stability and are non staining in nature. EXCEL RUBBEROIL 710 is aromatic type rubber processing oil containing to ASTM 101 type. Blended from speciality selected aromatic extracts products from further extraction of Lube Oil. Inspection of Excel Rubberoils CHARACTERISTICS EXCEL RUBBEROIL 245 EXCEL RUBBEROIL 541 EXCEL RUBBEROIL 710 Colour ASTM (Max) 2.0 3.0 8.0 Density @29.5Deg C gm/ml 0.8800 0.8900 0.9400 Kinematic Viscosity @40 Deg C, cst 30 to 32 20 to 22 20 TO 25 (@ 100 Deg ) Flash Point 190 160 200 Pour Point Deg C 0 -6 30 Aniline Point Deg C 96 78 50 Neutralisation number (mg/Koh/Gm) 0.05 0.05 0.1 ApplicationsEXCEL RUBBEROIL 245 is recommended as an ingredient for the manufacture of various Rubber products from both natural and synthetic rubber. It is used in the manufacture of Automotive tyres, tubes and many other moulded rubber goods and also in dark coloured Rubber goods such as battery casings, rubber bushes etc.. These are ideally suitable for processing natural, Styrene Butadiene Rubber, Isoprene, Butyl Rubbers and EPDM rubbers. EXCEL RUBBEROIL 541 is recommended for use in processing of rubber ofr the manufacture of automobile tyres and many other moulded rubber goods. These are ideally suitable for processing Styrence Butadience Rubber (SBR), Natural and Isoprence Butyl Rubber. EXCEL RUBBEROL 710 oil is suitable for natural as well as synthetics rubbers like Butadience Neoprene and Styrene Butadience Rubber (SBR). These are used in the Manufacture of automobile tyres, rubber treads and other dark coloured rubber goods Such as battery casings rubber bushes etc.