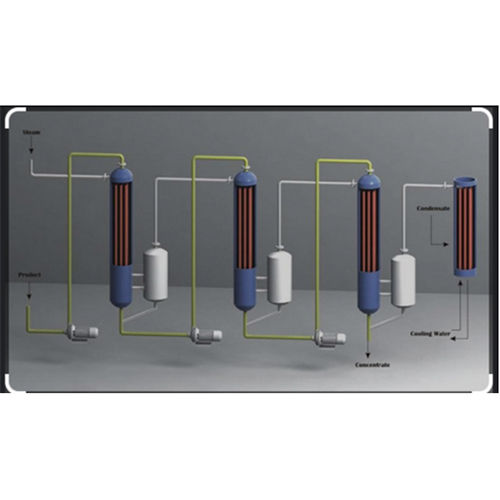

Salt Recovery Evaporation Plant

Price:

Get Latest Price

In Stock

Product Specifications

| Sample Available | Yes |

| Sample Policy | Contact us for information regarding our sample policy |

Product Overview

Key Features

Additional Information:

Salt Recovery Evaporation Plant is used to remove low boiler Solvents from Process Fluid.

In Waste water application, Stripper column can be used to remove COD percentage from the Effluent.

It will recover 90 percent of low boilers from waste water Effluent.

This system can also be used to recover pure solvent from the process fluid.

Company Details

Ketav Consultant has more than 17 years of expertise and experience in engineering Industrial Evaporator Plants, CEPT Plant, Evaporator Plants, Multiple Effect Evaporator Plants, Zero Liquid Discharge Evaporator Plant, Distillation Plants, Effluent Recycling Plant, etc. The company is a leading manufacturer, exporter, supplier and importer of the market creating competent, sustainable and economical solutions for optimising the processes of distillation, evaporating, recycling, etc., across industries. In addition, it is a trusted service provider of Erection, Commissioning and Debottling (Repair), Maintenance and other services. From lab scale study, pilot plant trials for mechanical and procedure, scale-up, procedure outlines, development, extras determination, venture execution, erection, charging, preparation to after deals administration, every single process is carried-out with matchless precision at its facility.

The company was formed in the year 2005 at Gandhinagar, Gujarat, India, by Mr. Kamlesh Patel, the Proprietor. His sharp business acumen and skills have enabled it to soar new heights of success within a short span of time. He aptly combines his knowledge with modern technologies so that the firm can create the finest product-line for many major industries.

Concepts of creativity, innovation and integration have enabled the company to build profitable solutions for better productivity and cost benefits of many customers. It also designs high-end products in customized specifications for meeting the needs of different applications and industries with perfection. With outstanding construction and configurations, these products are sure to provide economic efficiency and major profits to all clients.

With fully-fledged branch offices in Mumbai, Ankleshwar, Hyderabad, Tamil Nadu and Punjab, Ketav Consultant has been serving the needs of clients with excellence. The assembling offices are confirmed for ASME 'U stamp' and European PED 'CE mark' strategies. Company engineers and designers are trained to design innovative Zero Liquid Discharge Evaporator Plant, Distillation Plants, Effluent Recycling Plant, ATFD, Industrial Evaporator Plants, CEPT Plant, Evaporator Plants, Multiple Effect Evaporator Plants, etc., with unmatched features according to the demands and feedback of the patrons. Moreover, it has a vast distribution channel, huge storage units and efficient logistics facilities that help it deliver products in bulk to any part of the world backed with complete documentation as well as legalities.

Sectors We Serve

The company is a known name of the market serving the demands of the following sectors:

- Agitated Thin Film Dryer (ATFD) System

- Automobile Industries

- Caustic Recovery Plant

- Cement Industries

- Chemical, Dyes & Intermediate, Chemical Industries

- Common Effluent Treatment Plants

- Food Product Waste Water

- Glauber Salt Recovery Crystallizer System

- Pesticide Industry Waste Water

- Pharmaceutical & API Industries

- Product Concentration

- Starch Industry

- Steel & Metal Industries

- Sugar And Distilleries Industry

- Tannery Industries

- Textiles, Dyeing, & Spinning Mill Industries

Production Facilities

We have developed a well-equipped production unit located over a huge area of 10000 sq. mtrs. with sophisticated machinery and equipment to design matchless Multiple Effect Evaporator Plants, Zero Liquid Discharge Evaporator Plant, ATFD, Industrial Evaporator Plants, CEPT Plant, Evaporator Plants, Distillation Plants, Effluent Recycling Plant, etc. Our company has the following machines:

- Bending

- Tube Expanding

- Plasma Cutting

- Welding

- Drilling

- Lathe, etc.

We also have high-tech facilities to provide pilot plant trials to the patrons for serving their needs with perfection. Besides this, we also have the facility of high pressure pumps for tube cleaning.

Achievements

- Successfully supplied 9 maximal plants to common effluent treatment plants, tannery and textiles industries in the past 3 years in Tamil Nadu

- Installed 80 plants in the past 8 years in India for textile & dyeing industry

- Provided 18 plants to pharmaceutical industries and 35 concentration plants in India

- Supplied 30 MEE plants for pesticide, steel industry, dyes intermediate, dyes, organic chemicals, etc.

- Successfully finished revamping & improvement of 23 plants of multiple effect evaporation plants designed by other manufacturers

Clients

- Dabur

- D Décor

- Delphi- TVS

- Dynemic Products Ltd.

- ENDOC

- Godrej

- Glenmark

- Trident Group

- Actgen

- Alkem

- Amneal

- BKT

- Cadila

- Maharshi

- JSW and many more

Why Choose Ketav Consultant?

We, Ketav Consultant, have become the first choice of every leading business of the market as we fulfil the needs of CEPT Plant, Evaporator Plants, Multiple Effect Evaporator Plants, ATFD, Industrial Evaporator Plants, Zero Liquid Discharge Evaporator Plant, Distillation Plants, Effluent Recycling Plant, etc., with precision. Following are the reasons that have made us a prime name of the industry:

- Well-established engineering company offering unmatched Designing, Manufacturing, Installing & Commissioning solutions of Multiple Effect Evaporator Systems

- Attained expertise in the domain of Heat Treatment Plant and allied products

- Provides all kinds of reliable Process & Operational Solutions pertaining to different sectors

- Capability to fulfil orders of clients based in India, Oman, Dubai, Saudi Arabia and UAE

- Developed 200 Evaporators for meeting the needs of various industries and applications

Fact Sheet of Ketav Consultant

|

Nature of Business |

Manufacturer, Service Provider, Exporter, Supplier and Importer |

|

Business Location |

Gandhinagar, Gujarat, India |

|

Owner |

Mr. Kamlesh Patel |

|

Year of Establishment |

2005 |

|

No. of Employees |

150 |

|

GST No. |

24ADIPP0287H1ZH |

|

No. of R&D Staff |

3 |

|

No. of Engineers |

60 |

|

No. of Designers |

5 |

|

Monthly Production Capacity |

As per customers requirements and our schedule |

|

Key Customers |

|

|

Industry |

Multiple Effect Evaporation Plant |

|

Annual Turnover |

|

|

Building Infrastructure |

Permanent |

|

Size of Premises |

20000 square feet |

|

SSI Registration No. |

240061101198 |

|

Banker |

ICICI Bank |

|

PAN No. |

ADIPP0287H |

|

TAN No. |

AHMK03870G |

|

IE Code |

0807018643 |

|

EPF No. |

GJ/NRD/62450 |

|

Central Sales Tax No. |

24574100431C |

|

Value Added Tax Registration No. |

24074100431V |

|

Service Tax Registration No. |

ADIPP0287HST001 |

|

Excise Registration No. |

ADIPP0287HXM002 |

|

Payment Modes |

Cash, Credit Card and Cheque |

|

Shipment Modes |

By Road and Air |

Business Type

Exporter, Importer, Manufacturer, Service Provider, Supplier

Employee Count

250

Establishment

2005

Working Days

Monday To Sunday

GST NO

24ADIPP0287H1ZH

Related Products

Explore Related Categories

Seller Details

GST - 24ADIPP0287H1ZH

Gandhinagar, Gujarat

Proprietor

Mr Kamlesh Patel

Members since

16 Years

Address

Plot -21,25 -28, Juna Babalpura Patiya, opposite Avirat Metal, Dahegam, Gandhinagar, Gujarat, 382305, India

evaporation plants in Gandhinagar

Report incorrect details