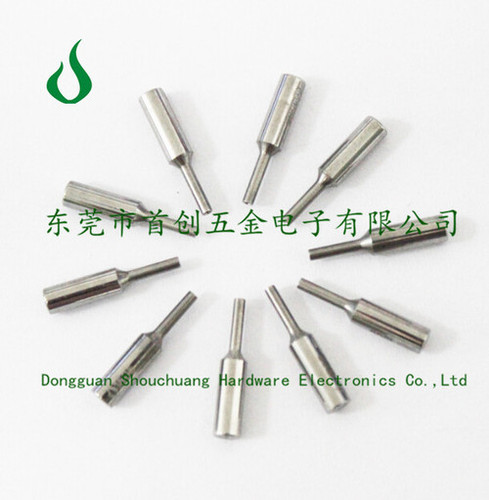

Sandblasting Gun And Sandblasting Nozzle

Price Trend: 40-80 USD

Get Latest Price

Minimum Order Quantity :

one

In Stock

Product Specifications

| Hardness | Ask customer service in detail |

| Connection Type | Ask customer service in detail |

| Medium | Other |

| Reinforcement | Ask customer service in detail |

| Shape | Ask customer service in detail |

| Cover | Ask customer service in detail |

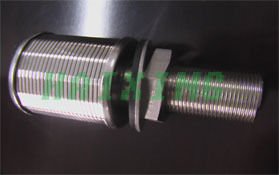

| Material | Metal |

| Temperature | Ask customer service in detail Fahrenheit (oF) |

| Pressure | eightkg kgf/cm2 |

| Inside Diameter | I+6 I+8 I+10 I+12 Millimeter (mm) |

| Outside Diameter | Forty-twomm Millimeter (mm) |

| Warranty | Ask customer service in detail |

| FOB Port | tianjin |

| Payment Terms | Telegraphic Transfer (T/T) |

| Supply Ability | Ask customer service in detail Per Day |

| Delivery Time | Spot Days |

| Sample Available | Yes |

| Sample Policy | Within a certain price range free samples are available |

| Packaging Details | Plastic box packing |

| Main Export Market(s) | Australia, Eastern Europe, Western Europe, Middle East, Central America, Africa, South America, Asia, North America |

| Main Domestic Market | All India |

| Certifications | Ask customer service in detail |

Product Overview

Key Features

Sand blasting is mainly used for some materials and parts that are not easy to adopt conventional treatment methods, such as high-strength steel which is very sensitive to hydrogen embrittlement, magnesium alloy parts which are easily corroded in aqueous solution, cast iron parts, machine tool bases and water gates. .

The purpose of sand blasting is to clean the surface of the parts, such as scale, rust, carbon deposits, welding slag, paint marks or wear marks, reduce the surface roughness of the parts, and increase the bonding force between the cover layer and the substrate. This technology is applied in the coating process. Extremely common.

1 Classification of sandblasting

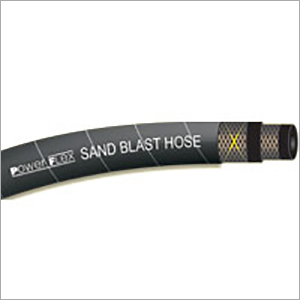

Sand blasting can be divided into dry blasting and wet blasting. At present, dry blasting is still the main application. The sand grains are quartz sand, silicon carbide and river sand, of which quartz sand is most commonly used.

The quality of sand blasting depends on factors such as part material, air cleanliness, pressure, nozzle diameter and abrasive grain size.

Wet blasting is mainly to reduce sand and prevent pollution. Wet blasting is mainly water blasting, m (water): m (abrasive) is about 7: 3, and water should be added 1. 5% ~ 2. 0% rust inhibitor to prevent rusting of parts.

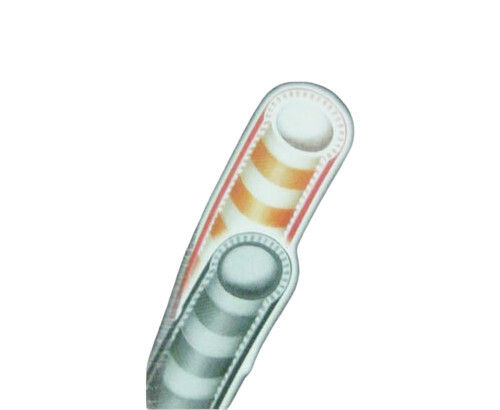

The working principle is still to use clean compressed air separated by oily water, press the prepared into the nozzle, and then spray it through the nozzle to the surface of the part. It should be constantly stirred during work to prevent precipitation of the abrasive.

In order to improve the spraying method, when the spraying method combined with the nozzle and the sand blasting gun is adopted, the effect is ideal, and the effect of prolonging the service life of the nozzle can also be achieved.

Company Details

Business Type

Exporter, Manufacturer, Wholesaler, Retailer, Fabricator

Employee Count

30

Establishment

2006

Working Days

Monday To Sunday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

Seller Details

Hebei, Hebei

Ceo

Mr Hebei Xingchen

Address

Floor 3, Wanda Plaza, Yuhua District, Shijiazhuang City, Hebei, Hebei, China

sandblast hose in Hebei

Report incorrect details