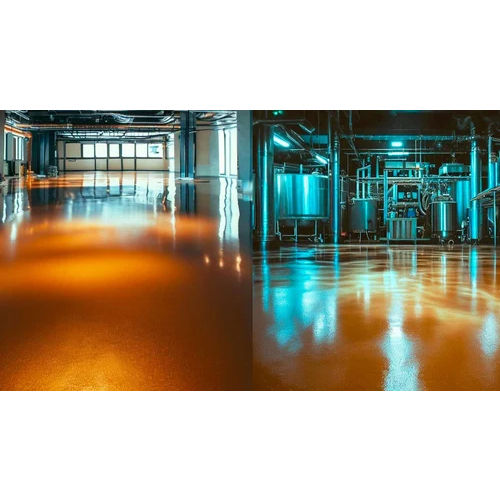

Self Leveling Seamless Epoxy Flooring For Interior Residential Home

Price:

Get Latest Price

Product Overview

Key Features

Epoxy floor paint is a kind of high-strength, wear-resistant and beautiful floor. It has the advantages of no seam, solid texture, good chemical resistance, anti-corrosion, dustproof, convenient maintenance and low maintenance cost.

Epoxy floor can be designed according to different application requirements: such as thin layer coating, 1-5mm thick self-leveling floor, non-slip wear-resistant coating, mortar coating, anti-static, anti-corrosion coating. Epoxy floor can be roughly divided into: epoxy grindstone floor, epoxy resin sand sand floor, epoxy self-leveling floor, epoxy mortar type floor, epoxy plain coating floor.

classification

a. Epoxy plain coating floor (the place where the general workshop is dust-proof and the environment is not high).

b. Epoxy self-leveling floor (clean room, high purification industrial production area).

c. Epoxy anti-static floor (manufacturing workshop for electronics industry that is required to resist static electricity).

d. Epoxy mortar wear-resistant floor (the factory has heavy-duty running workshops, warehouses, passages, underground parking lots, etc.).

How to choose epoxy floor paint?

In order to help customers who use floor decoration protective coatings to correctly select the type of floor and effectively control the construction cost, it is recommended that customers start with the following factors:

Mechanical performance requirements

The main three aspects are as follows:

1. Abrasion resistance: Which vehicles will travel when the floor is in use;

2. Pressure resistance: how much load the floor will bear when it is used;

3. Impact resistance: Whether the impact force will cause the floor surface to peel off;

Chemical performance requirements

The main considerations are as follows:

1. Acid and alkali resistance: The type and concentration of corrosive chemicals used.

2. Solvent resistance: solvent type and contact time when used.

Floor location status

According to the location of the floor on the underground floor or the ground floor, do you need to prevent moisture or choose a special moisture-proof floor.

Base condition

1. Base strength: general requirements compressive strength a Y 20Mpa

2. Flatness: Do you need to repair with epoxy mortar.

3. Self-leveling is generally required before ground construction.

Aesthetic requirements

1. Color requirements: Do you need a color division area?

2. Brightness requirements: Is it a matt or glossy type?

3. Flatness requirements: Is there a requirement for the flatness of the floor?

Safety requirements

If the floor is in a greasy environment or on a ramp, you need to choose a non-slip floor; if you are in a special place such as a gas station or oil depot, you need to choose anti-static and explosion-proof.

Construction process

1. Base surface treatment;

2, apply the primer;

3, apply putty;

4. Grinding and vacuuming;

5, apply the paint;

The primer is made of epoxy resin primer main agent: curing agent, and the curing is evenly cured for about 10 minutes. It is sprayed once with a wool roller. The primer is mainly used to close the base layer and seal the water and dust.

6. Filling and processing

Make Epoxy mortar with epoxy varnish & quartz sand to fill expansion joints and cracks.

7. Apply the epoxy Middle coat.

8. Apply the epoxy finish coat.

9 Engineering maintenance

Technical indicators

Drying time surface dry a 4

Hard work a 24

Adhesion (level) a 1

Pencil hardness a Y2H

Impact resistance 50 passed

Flexibility 1mm through

Wear resistance (750g/500R, weight loss g) a 0.03

Water resistance No change for 48 hours

Resistance to 30% sulfuric acid for 7 days without change

40% sodium hydroxide resistant, no change for 7 days

Gasoline resistant 120# 7 days no change

Resistant to lubricating oil for 7 days without change

Nine: performance requirements

1.Cleanliness requirements: For places with high cleanliness requirements, self-leveling floors should be used.

Company Details

LinRay New Material Limited Company, is a professional China manufacturer of paint and coatings. we have been in the business of paint and coating for over 18 years. LinRay is our brand name. Our company focused on research and manufacture of wall painting and acrylic paint which is used for architectural coatings. Our main products includes interior paint, exterior paint, ceiling paint, wall texture paint, natural stone paint, liquid granite paint, garage floor paint, epoxy floor paint, enamel paint and so on. Our factory is located in ShunDe, FoShan. Factory covers area of 30,00 square meters and company staff reaches more than 100. Factory is designed according to the standard of dangerous chemical cargo, we have advanced full automatic production line and inspection equipments. Factory annual production capacity is more than 200,000 tons of paint. Our company culture is to give customers GOOD quality products at competitive prices. We will be your honest and reliable business partner, to get a long term win win cooperation. We sincerely welcome you to visit our factory and negotiate business together. You can visit our website linraypaint dot com. You can directly whatsapp me at +86 189 4246 3175 or email me feiwang0422 at gmail dot com.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

30

Establishment

2011

Working Days

Monday To Sunday

Related Products

Explore Related Categories

Seller Details

Foshan, Guangdong

Sales Director

Mrs Grace Wang

Address

No - 202, 2, Ruian Building, Honggang Industrial Area, Shunde, Foshan, Guangdong, 528300, China

epoxy floor coatings in Foshan

Report incorrect details