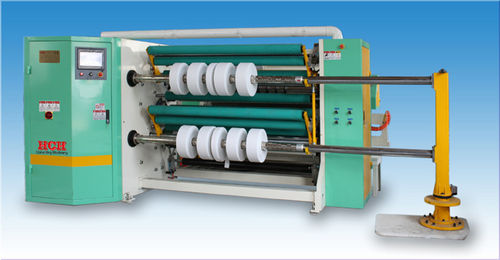

Semi Automatic Jrx2200 Rewinding Machine Power Source: Electricity

Price Trend: 20000.00 - 40000.00 USD / Set

Get Latest Price

Minimum Order Quantity :

1 Set

Product Specifications

| Product Type | Cutting Machine |

| Power Source | Electricity |

| Operating Type | Semi Automatic |

| FOB Port | QINGDAO |

| Payment Terms | Letter of Credit (L/C), Telegraphic Transfer (T/T), Paypal, Western Union |

| Main Export Market(s) | Western Europe, Australia, North America, Eastern Europe, Central America, Middle East, South America, Asia, Africa |

| Main Domestic Market | All India |

Product Overview

Key Features

The working principle of the machine is as follows: place the paper roll taken from the reeling machine on the unwinding frame, and the pneumatic brake keeps the paper sheet at a constant tension. The paper sheet is led down by the paper unwinding frame along the paper guide roller, longitudinally cut by the slitting system, and then passed through the banana roller and the paper guide roller device, and is winded on the paper bobbin on the back support roller. The paper roll is drived by the backup roller to run, thereby pulling the entire sheet forward.

The slitting system of this model adopts the form of paper-down structure, which improves the stability of the equipment and enhances the effect of the equipment.

This machine is usually installed after the reeling machine or it can be installed separately. According to the different drive position, it is devided to the left (Z) and right (Y) arrangements. Viewed the drive section in the direction of the paper exit,if the drive is located on the right hand side, it is right arrangement and if on the left hand side it is left hand arrangement.

Technical Parameters

1. GSM of paper: 100-300g/m2

2, The net width of the paper: 2200mm

3. Working speed: 600m/min

4, The form of paper threading: paper-down form

5, The speed of crawl: 10-25m / min

6, Largest base paper diameter: A A 1800mm

7, Largest finished roll diameter: A A 1500mm

8, Rail width: 3200mm

9ALA A Motors:

Support roll(AC variable frequency motor)

BPY225M-4 45kW 1440rpm 1 set

Bottum knife motor

BPY802-2 0.75kw 2860rpm 3 sets

Structure description

The rewinder consists of a paper unwinding device, a slitting device, frame, transmission device, support roller device, a tightening device, a press roller device, a push roller device, a threading device, a paper discharge device, guide roller,multi-section banana roller, air control system, hydraulic system, electronic control system and other components.

1.Unwinder frame device

The paper unwinder frame device is composed of a frame, a clutch, a pneumatic brake device and a longitudinal adjustment device.

Pneumatic brakes is used for applying tension to the sheet. During the braking process, the pneumatic brake is cooled by circulating water.

The longitudinal adjustment device is used to adjust the parallelism of the paper roll and the main unit.

The unwinder frame includes:

1. bracket, two pieces (welding parts)

2. Bearing housing, two pieces (welding parts)

3. pneumatic brake, 1 set(two sets of brake arms)

2.Slitting device:

Each bottom knife is separately driven by an AC motor, and the motor control adopts AC frequency conversion for speed regulation. The bottom knife speed has a tracking function with the paper sheet speed, generally 10-20% higher than that of the paper speed. The difference between the bottom knife speed and the paper sheet speed can be adjusted according to the paper type to ensure that the slitting surface is flat and the paper roll is prevented from biting each other and spliting not easily. The bottom knife brake is an electrical energy brake.

The diameter of the top round knife is A A 190mm, there are three, and its lifting and falling movements are all manually operated.

Two A A 190 paper guide rollers are used to support the sheet and let the sheet enters the slitting device at a constant angle.

A pipe port of shredded paper fan is installed under the rear paper guide roller, and the shredder fan is used for processing the paper edge on both sides after cutting, and the paper edge is discharged through the pipe.

2.1Paper guide roller (A A 190*14*2450), 1 piece (seamless tube)

2.2 Beam (A A =20), 1 piece (welding piece)

Company Details

Business Type

Exporter, Manufacturer, Supplier, Producer

Employee Count

30

Establishment

2009

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

Seller Details

Qingdao, Shandong

Proprietor

Mr Eric Qi

Address

9TH FLOOR, GEMINI TOWER B, 88TH CHUNYANG ROAD, Qingdao, Shandong, 266109, China

paper rewinding machine in Qingdao

Report incorrect details