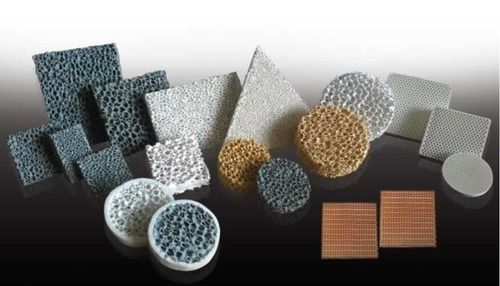

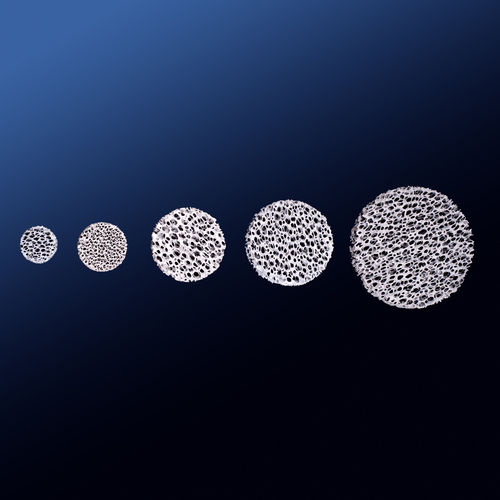

Silicon Carbide Ceramic Foam Filters - 30-600 Mm Thickness, 6600 Kg/day Capacity | 95% Efficiency, Non-woven Design, 1500°c Working Temperature, Enhanced Metal Flow Control

Price:

Get Latest Price

Product Specifications

| Efficiency (%) | 95% |

| Capacity | 6600 Kg/day |

| Resistance | 1500 |

| Type | Non-Woven Filter |

| Material | OtherPP |

| Thickness | 30-600 Millimeter (mm) |

| Thermal Shrinkage | 6 |

| Working Temperature | 1500 Celsius (oC) |

| Application | Casting filter |

| FOB Port | TIANJIN ,SHANGHAI ,IN CHINA |

| Payment Terms | Others, Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA) |

| Supply Ability | 4000000pcs Per Month |

| Delivery Time | 10-15 Days |

| Sample Available | Yes |

| Sample Policy | Free samples are available |

| Packaging Details | cartons with pallet |

| Main Domestic Market | All India |

| Certifications | . It has a maximum application temperature of up to 1500 centigrade. The application of silicon carbide ceramic foam filters has various advantages. One is that the flow of metal is effectively calmed-down due to the complex 3D structure of the filter, thus sand erosion is reduced and the filling of mould is improved. Another advantage is that the ceramic filter removes solid inclusions like e. G. Slag or reaction products of melt treatment from the liquid metal. Therefore, the metal quality is improved and cleaning and repair work is reduced. |

Product Overview

Key Features

Company Details

Business Type

Exporter, Importer, Manufacturer, Supplier

Employee Count

300

Establishment

2013

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Certification

ISO 9001:2015

Related Products

Explore Related Categories

Seller Details

Cangzhou, Hebei

Sales Manager

Ms Kerry

Address

Guanting Industrial Park, Cangzhou City, Hebei Province China, Cangzhou, Hebei, 061034, China

ceramic foam filters in Cangzhou

Report incorrect details