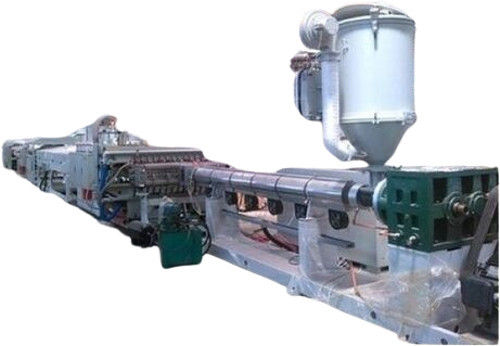

Automatic Single Layer And Multi Layer Pe Sheet Extrusion Machine With 1 Year Of Warranty

Price: 100000 USD / Set

Get Latest Price

Minimum Order Quantity :

1 Set

In Stock

Product Specifications

| Type | Plastic Extrusion Machine |

| Capacity | 500 Kg/hr |

| Computerized | Yes |

| Automatic Grade | Automatic |

| Control System | PLC Control |

| Drive Type | Direct |

| Screw Diameter | 1000 Millimeter (mm) |

| Power | 75 Watt (w) |

| Weight (kg) | 20 Tonne |

| Dimension (L*W*H) | 20*2.5*2.5 Meter (m) |

| Color | Standard |

| Warranty | 1 Year |

| FOB Port | Wuhan |

| Supply Ability | 1 Per Month |

| Delivery Time | 60 Days |

| Sample Available | Yes |

| Sample Policy | Free samples available with shipping and taxes paid by the buyer |

| Packaging Details | Wooden Case |

| Main Domestic Market | All India |

| Certifications | ISO9001:2008/CE |

Product Overview

Key Features

Sheet Extrusion Line Model No.:HDB130/90-2200HDB120/80-1400,HDB110/65-1000

Sheet Width: 2000mm/1200mm/800mm

Sheet Thickness: 0.5~2mm/0.3~2mm/0. 1~0.8mm

Equipment Speed: 15m/min; 20m/min;20m/min

Roller Diameter: 600mm/500mm/400mm

Production Capacity: 500-600kg/h; 400-500kg/h; 200-300kg/h

Features:

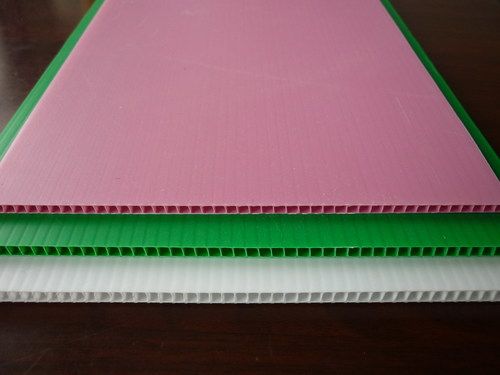

1. The coat-hanger type sheet die features a 2-port manifold for precise melt flow control.

2. Accurate temperature control of provides an ideal environment for plasticization. It also helps ensure the uniform thickness of the extrudate.

3. The plastics extrusion die is followed by 3 rolls downstream which are arranged horizontally, vertically, or at an angle of 45A A A A with respect to the ground. The rolls are used to solidify the molten sheet extrudate and impart gloss to the sheet surface. They are vertically adjustable in height, thus providing more options during operation for high quality solidified plastic sheets.

4. Advance sheet cutter allows the exact number of sheets to be cut to the required length.

5. High-torque motor is used to control the sheet take-up speed and tension force on the sheet extrusion line, in an attempt to yield flat rolls of thin plastic sheets.

Company Details

The company develops and produces plastic machinery and packaging machinery, and has a number of technological transformation achievements with independent intellectual property rights. At present, the products have been sold to more than 20 provinces and cities in China, and exported to the United Kingdom, Bulgaria, Turkey, Vietnam, South Korea, Japan, Malaysia, India, Thailand, Mexico, Canada and other countries and regions. It has established long-term good cooperative partnerships with major steel companies, auto parts and other large enterprises. The company has always adhered to the business philosophy of integrity, equality, and customer benefits first. The products implement GB/T 19001-2000 idt ISO 9001:2000 quality system management, and provide customer support and personnel training.

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

200

Establishment

2005

Working Days

Monday To Sunday

Related Products

Explore Related Categories

Seller Details

Wuhan, Hubei

Sales Representative

Mr Peng Wei

Members since

6 Years

Address

No.61, Yinbai Road, Jinghe Street, Dongxihu District, Wuhan City, Hubei Province, Wuhan, Hubei, 430044, China

plastic sheet extrusion machine in Wuhan

Report incorrect details