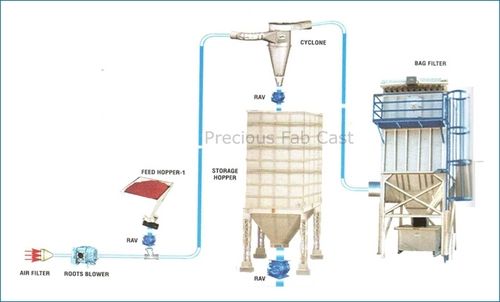

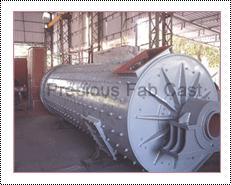

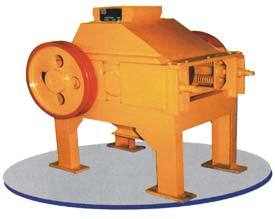

Normal 0 false false false EN-US X-NONE X-NONE /* Style Definitions */ table.MsoNormalTable {mso-style-name:"Table Normal"; mso-tstyle-rowband-size:0; mso-tstyle-colband-size:0; mso-style-noshow:yes; mso-style-priority:99; mso-style-qformat:yes; mso-style-parent:""; mso-padding-alt:0in 5.4pt 0in 5.4pt; mso-para-margin-top:0in; mso-para-margin-right:0in; mso-para-margin-bottom:10.0pt; mso-para-margin-left:0in; line-height:115%; mso-pagination:widow-orphan; font-size:11.0pt; font-family:"Calibri","sans-serif"; mso-ascii-font-family:Calibri; mso-ascii-theme-font:minor-latin; mso-fareast-font-family:"Times New Roman"; mso-fareast-theme-font:minor-fareast; mso-hansi-font-family:Calibri; mso-hansi-theme-font:minor-latin;} Slag Crushing Machinery We present an extensive range of Slag Crushing Machinery which is manufactured using premium quality raw materials and advanced technology in compliance with the international quality standards. Our range is widely popular for its high durability, supreme quality and high efficiency. This range of Slag Crushing Machinery is used in large number for slag crushing. Also, we are able to meet the bulk requirements of our customers within stipulated time frame and these are available at the most affordable rates. Further Details: Precious an ISO 9001:2000 certified company, which is engaged in developing & manufacturing different type of crushing & Pulverising machines & system for last more than 18 years has developed steel slag crushing plant. In fact it is being observed that the slag coming out from different type of Furnaces contains even up to 10-15% of steel metal hence if this could be separated, it give a very good saving out of the waste material (slag). Further the separated slag, which comes in the form of corse powder become easily manageable to dispose it off. Precious has developed the plant with full automation of transferring material from one stage to other till, metal & slag are separated fully. On the very first stage slag is crushed in the Jaw Crusher than it is transported through a conveyor to Roll impector mill, for secondary crushing. Now this crushed material goes to the hopper with the help of a bucket elevator which spreads the material on two stage magnetic separator, where most of the metal is being separated at first stage while remaining is separated on second stage. Crushed slag collected as a heap while removed metal goes to a Ball mill. Ball Mill is so designed that even the small particles with metal are being separated and almost pure metal is being collected at the other end of the Ball Mill.The complete plant (system) may be designed to suit your site condition, available manpower & required automation.Different models of plants are available to meet your requirement to process slag from 2 tons per hour to 20 T/hr. However it could be designed for higher capacity also.