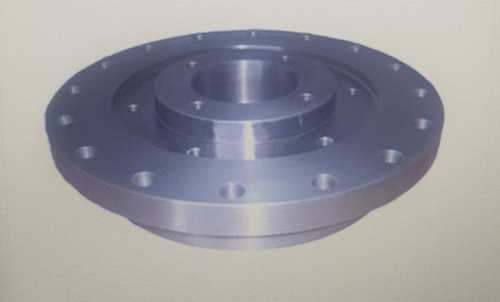

Being a quality conscious firm, we are engaged in manufacturing and exporting premium quality Stainless Steel Investment Casting that is used for shaping various products. It is available in various designs, sizes and shapes to meet the diverse needs of the clients. The offered product is manufactured by our dexterous professionals using optimum quality stainless steel and advanced techniques. Our offered Precision Steel Investment Castings is highly acknowledged for its sturdy construction, rust resistance, durability and dimensional accuracy.Key Features:Durable and corrosion resistant surface finishHigh efficiency and rugged constructionMaterials: stainless steel, alloy steelProcess type: water glass, silicon gelSurface finish: polishing, Dacromet and zinc platingCoordination measuring (CMM), chemical analysis, mechanical testing & metallographyliquid-penetration inspection, Ultrasonic inspection and X-rayPrototype development: low, medium & high volume productionWhat is Investment Casting? Also known as lost-wax casting, Investment casting is an age-old metal-forming technique, mainly used to develop intricately detailed near-net-shape castings. It is also one of the most advanced of the metallurgical arts. Today, this technique utilizes the latest scientific advances in CAD-CAM design & manufacturing, automated systems, conveyorization, robotics, countergravity casting techniques, etc., to introduce premium quality and innovative investment casts.The origin of the term 'investment' can be traced from the solid moulding process that has been in practice for the last 5000 years. And investment casting is reckoned to be one of the oldest known metal shaping mechanisms. This process necessitates plaster-type-material invested into a container keeping the assembled tree of plastic patterns which are corresponding to the casting allowing the fabrication of precision components. Once the plaster is dipped, the disposable patterns are burnt in order to create a hollow cavity into which the metal is finally poured.Advantages of Investment Casting:Excellent Design FlexibilitySmooth surface can be acquired without parting lineGood Dimensional AccuracyThe process can be used for casting more than 120 ferrous & nonferrous metalsPrecision components can be created with complicated shapeCan be used to replace die-casting where short runs are involvedGet rid of unwanted metal & weight from non-functional areas of the partThe Process of Investment Castings It is a core & effective process of producing small complex components, and it is also perfect for metallurgical sound casting with close tolerances. Below the Process of Investment Castings. Wax patterns production through metallic dies that show exact replica of the needful castings. This procedure is performed under controlled atmosphere in order to have dimensional stability.Construction of ceramic shells of required thickness as well as strength, encompassing wax patterns by creating thin refractory coats layers, in well-controlled atmospheric conditions.De-waxing of the shells after adequate drying, so as to drain out the wax from cavity of shell. Backup of the de-waxed ceramic shell at high temperature, so that necessary hot strength of the shell can be achieved. Burnout unwanted wax matter for the impurities of ceramics. Pouring of the shells with clean metal, as per requisite specifications.Heat Treatment of SS investment casting partsFettling, Finishing and Cleaning of Casting Components, and then visual as well as dimensional inspection, making it perfect for use. PRODUCT DETAILS Condition New Brand ALLTECH Country of origin India Suitable for All kind of Investment Castings Components Material Alloy Steel, All engineering grade material PAYMENT DETAILS Payment terms Against LC Price Factory Price Quantity As per customer requirement Port JNPT (MUMBAI) PACKAGING & DELIVERY Packaging Details Sea worth export packaging Delivery Details 4 to 6 weeks