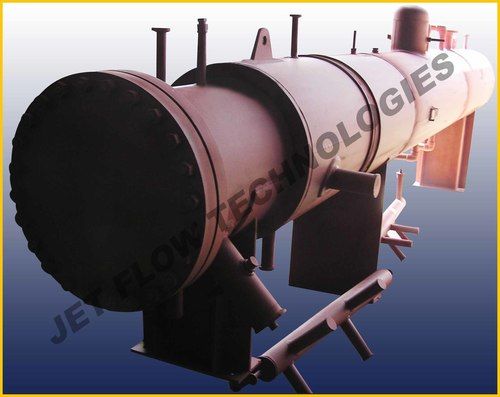

Steam Jet Thermocompressor - Multi-stage System For Efficient Low-pressure Steam Boosting | High-pressure Motive Steam Utilization, Energy And Fuel Savings, Versatile Applications

Price:

Get Latest Price

In Stock

Product Specifications

| FOB Port | Mumbai, INDIA |

| Payment Terms | Letter of Credit at Sight (Sight L/C), Letter of Credit (L/C), Telegraphic Transfer (T/T) |

| Main Export Market(s) | South America, Africa, Western Europe, Central America, Eastern Europe, Australia, Middle East, Asia, North America |

Product Overview

Key Features

If the objective is to recover the latent heat content of the low-pressure suction vapor for process use, the device is called a thermocompressor. If the objective is to pull a vacuum on a process vessel, the device is called an ejector.

Boosting Steam Pressure and Temperature with Thermocompressors-Single- or multi-stage thermocompressors are used to boost low-pressure vent steam to a useful higher pressure and temperature. When high-pressure motive steam is available, thermocompressors can be economically used for compression ratios up to 6:1 (absolute pressure of supply steam/suction steam).

High-pressure motive steam supplied to the thermocompressor expands in a converging-diverging nozzle to convert pressure energy to kinetic energy. Vent steam supplied to the suction port is entrained into this low-pressure/ high-velocity jet, where mixing occurs. The diffuser portion of the thermocompressor reconverts the kinetic energy of the mixture back into pressure. The intermediate discharge pressure is between the pressures of the motive and low-pressure suction steam. Discharge pressure is determined by the compression ratio (i.e. the ratio of the pounds per hour [1b/hr] of motive In steam supplied to the lb/hr of low-pressure suction steam entrained).

Thermocompressor capacity of the device is dictated by the availability of motive steam, motive and suction steam pressure, and discharge steam pressure requirements. Applications include drying and heating, multi-effect evaporators, vulcanizers, reboilers, strippers, condensate receiver tanks, and solvent extraction processes etc.

Company Details

Focusing on a customer-centric approach, Jet Flow Technologies Pvt. Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Coal & Coke in bulk from Jet Flow Technologies Pvt. Ltd. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer

Employee Count

54

Establishment

2005

Working Days

Monday To Friday

Payment Mode

Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

Seller Details

Chennai, Tamil Nadu

Sales Head

Mr. Rajiv Goel

Address

Level 5, Tamarai Tech Park, SP Plot No. 16-19&20A, Thiru Vi Ka Industrial Estate, Guindy, Chennai, Tamil Nadu, 600032, India

steam jet ejectors in Chennai

Report incorrect details