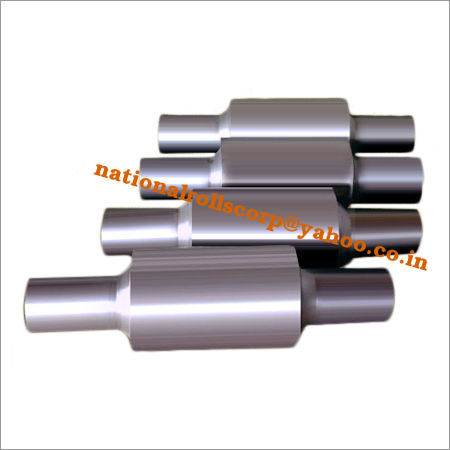

Steel Chill Rolls - Temperature Controlled Design, Optimized Heat Transfer For Enhanced Sheet Extrusion And Film Finishing

Price:

Get Latest Price

Product Overview

Key Features

A cored roll, usually temperature controlled with circulating water, which cools a molten polymer web on contact before winding.

Application

The fundamental knowledge from a basic understanding of roll design, function, and construction can help when purchasing a new roll, evaluating a new product or process, and troubleshooting.

The long experience of our foundry men and adequate selection of raw materials as well as the accurate laboratory testing of every single casting have enabled us to produce mill rolls of proper hardness and adequate ductility of hardened layer.

A chill roll primarily acts as a heat transfer and finishing device in the extrusion of flat sheet and cast film and in coating operations. Although these processes are different, the design criteria are the same roll load, face deflection, and heat removal rate. The functional aspects of a roll will vary considerably from process to process. The process and product predicate roll construction, materials, and surface finish. All these factors require consideration to achieve a properly designed and functioning chill roll. The first primary design principle is roll load in pounds per linear inch. Roll load is the amount of load applied to a web by an air or hydraulic actuating system. Equations are available in the paper to calculate roll load.

Company Details

Business Type

Exporter, Importer, Manufacturer, Supplier, Trading Company

Employee Count

40

Establishment

1970

Working Days

Monday To Sunday

GST NO

03ABWPP1402C1Z2

Certification

ISO 9001

Related Products

Explore Related Categories

Seller Details

GST - 03ABWPP1402C1Z2

Malerkotla, Punjab

Director

Mr. Puneet Dhingra

Members since

16 Years

Address

C-5, Industrial Area, Malerkotla, Punjab, 148023, India

chilled rolls in Malerkotla

Report incorrect details