Stesalit Dryer Temperature Controller For Tea Factory- Sdtc Application: Commercial

Price:

Get Latest Price

In Stock

Product Specifications

| Product Type | Stesalit Dryer Temperature Controller For Tea Factory- SDTC |

| FOB Port | Kolkata |

| Payment Terms | Cash Advance (CA), Cheque, Letter of Credit (L/C), Telegraphic Transfer (T/T), Others, Cash on Delivery (COD), Cash Against Delivery (CAD), Letter of Credit at Sight (Sight L/C), Cash in Advance (CID) |

| Supply Ability | 10 Per Month |

| Delivery Time | 6-8 Week |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | Export Standards |

| Main Export Market(s) | Africa, Asia |

| Main Domestic Market | All India |

| Certifications | Industrial Automation for Tea Industry |

Product Overview

Key Features

This is For achieving Quality by optimum use of coal/Gas and electrical energy Basics of Tea Drying at Dryer in Black Tea / CTC Tea Manufacturing:

Basics:

The oxidized leaf is passed into a hot air dryer for about twenty minutes where the moisture content is reduced to just 3% - 4 % and the familiar black color of CTC tea develops.

There are main two objectives to develop black Color of Tea:

1. To capture / halt the reaction time of enzyme particle and oxidation time.

2. To remove the moisture from the leaf particles to produce a good quality of Black tea.

The following factors are responsible for drying the tea properly

and produce a Quality..:

1. Maintains the constant Temperature at Inlet and Exhaust Air.

2. Maintain the volume of air.

3. Maintain the Feed Rate / quantity of Leaf Fed.

4. Period of Time (Residence Time of Dryer / Throughput Time).

SDTC Developed by Stesalit:

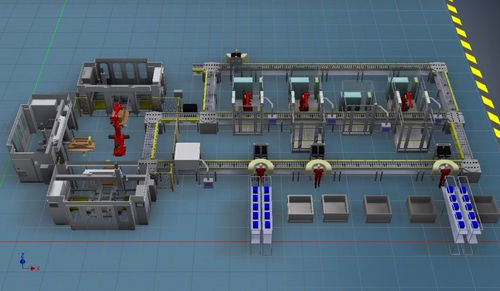

Considering the above all facts and based on valuable feedback & data from leaders in tea manufacturing industry, after successful trial run STESALIT has introduced a new product SDTC (Intelligent Dryer Controller) to monitor and maintain the desirable parameters like feed rate at dryer, dual drying inlet temperatures ( T1 & T2) and the residence time / throughput time of dryer. Our system will maintain the above mentioned parameters. It will ensure the following features related to tea made quality elevation.

1. Inlet Temperature T1 will control by our very successful product Coal Air Ratio Controller (CARC-04).

CARC-04 will control the Chain grate motor speed, FD fan speed and ID fan speed of heater.

By varying the following motor speed the system controls the T1 temperature within 1C.

2. Our SDTC controls the speed of Feed conveyor of Dryer and maintain the wet end temperature (popularly known as T3). This will ensure the even feeding based on a user settable Temperature at T3 and deactivation of enzyme (bio-chemical reactions) at the wet end of the dryer.

3. Our SDTC controls the speed of cold air fan speed of dryer in turns to maintain the second Inlet Temperature (popularly known as T2) which contributed the blackness of tea made.

4. Our SDTC controls the magnitude of vibro-mechanism and in turn maintains the throughput time and Final exhaust temperature (popularly known as T5). With controls the vibro mechanism, ensure the proper interaction in between carbohydrates with Amino acids which will turn leads to the formation of flavor components.

Salient Features of Intelligent Dryer Controller:

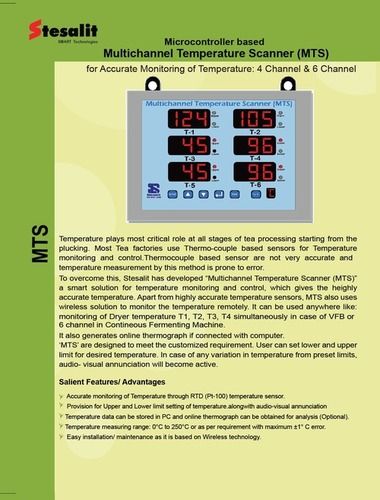

Maintained constant temperature at Dryer Inlet (T1) results in consistent and enhanced quality of Tea made.

Maintain the constant temperature at T2 for ensuring the proper cooking of fed material at Dryer.

Maintain the Fed Conveyor speed and T3 Temperature for ensuring the proper feeding in dryer .

Maintain the Vibro mechanism speed of dryer and T5 temperature for ensuring proper blackness of tea made.

Minimize production cost by optimum use of coal and electrical energy.

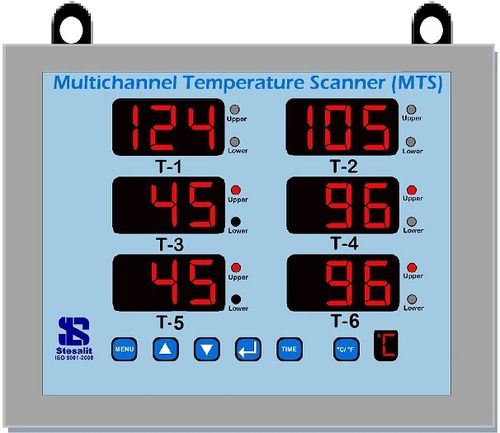

Dual Line Digital temperature Indicator cum Controller console.

High accurate RTDs are used for measuring the temperatures at dryer. Resistance Temperature Detectors (RTDs) are ideal for industries where accurate temperature measurement is required. The sensors measures over a range from -199.9C to 650C.

Company Details

Focusing on a customer-centric approach, Stesalit Systems Limited has a pan-India presence and caters to a huge consumer base throughout the country. Buy Tea & Coffee Machines in bulk from Stesalit Systems Limited at Trade India quality-assured products.

Business Type

Supplier, Trading Company

Employee Count

6

Establishment

2017

Working Days

Monday To Sunday

GST NO

19AAPCS0996R1Z2

Payment Mode

Others

Certification

ISO 9002

Related Products

Explore Related Categories

Seller Details

GST - 19AAPCS0996R1Z2

Kolkata, West Bengal

Manager- Sales & Marketing

Mr Madhav Dasgupta

Address

B No 71 7, PARK STREET, Kolkata, West Bengal, 713210, India

automation equipment in Kolkata

Report incorrect details