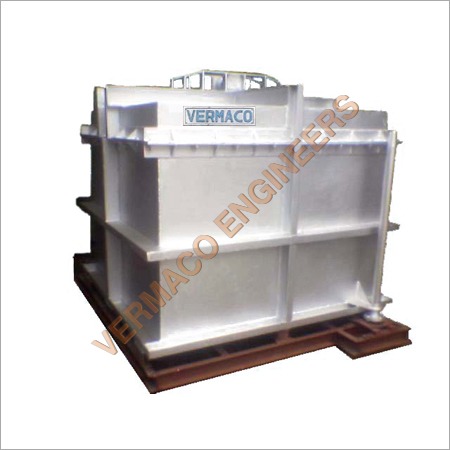

Temple Furnace

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Lead Scrap |

| Fuel | Wooden Coke |

| Air Supply | Fd Fan |

| Process | Manual Fired |

| Outlet | Bottom Pit |

| Type | Single/Double |

| Application | Lead Production |

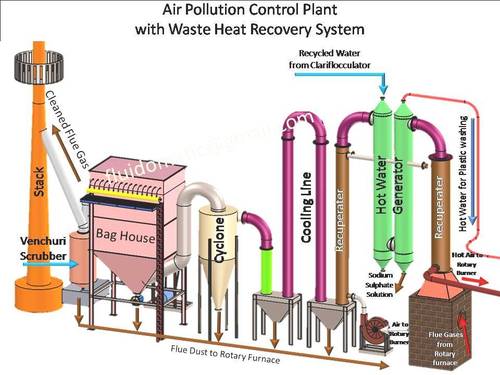

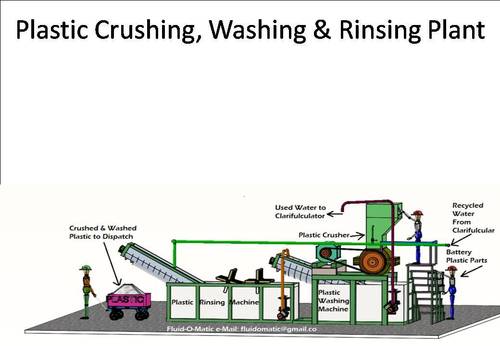

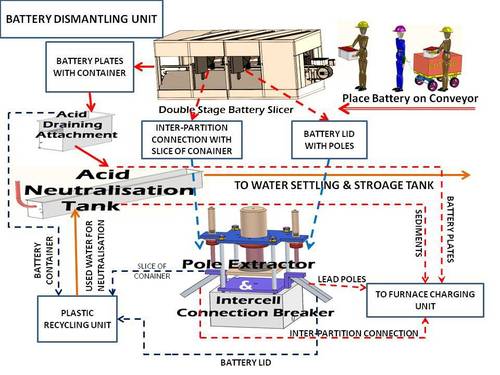

| Features | Lead Recovery, Manual Firing, Slag Separation, Ingot Moulds, Air Pollution Control |

Product Overview

Key Features

TEMPLE FURNACE IS OF TWO TYPES:

a c SINGLE TEMPLE FURNACE

a c DOUBLE TEMPLE FURNACE

Company Details

we, FLUIDOMATIC have emerged as a one stop solution for the best battery manufacturing and USed Battery Breaking & Recycling machines and Its allied technology. We are a renowned company dealing in various battery manufacturing machines and allied products. We came into existence in the year 1989 and since then have achieved tremendous success in manufacturing premium quality machines. Today, we are a leading manufacturer, and exporter of Used Battery Recycling Plant, Battery Making Plant, such as Battery Assembly Line, Battery Heat Sealing Machine, Battery Recycling Plant, Battery Breaking Plants, Lead Smelting Plants, Lead Recycling Machines, & Battery Part making Machines, Container Punching Machine, Inter Partition Welding Machine, Stress Testing Machine, Lid Heat Sealing Machine, Air Leakage Testing Machine, Short Circuit Testing Machine, Grid Casting Machine, Grid Pasting Machine, Drying & Curing Oven, Incinerators, Dead Human Cremation Furnace, Waste Recycling Plant, E-Waste Recycling Plant, etc.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

30

Establishment

1989

Working Days

Monday To Sunday

GST NO

09AUUPS7718P2Z7

Certification

IS0 9001:2015, CE Certified

Related Products

Explore Related Categories

Seller Details

GST - 09AUUPS7718P2Z7

Noida, Uttar Pradesh

Ceo

Mr G D Sharma

Members since

18 Years

Address

B-24, Sector-60, Noida, Uttar Pradesh, 201301, India

heat treatment furnaces in Noida

Report incorrect details