Thermography Testing Services

Price:

Get Latest Price

In Stock

Product Specifications

| Payment Terms | Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA) |

| Delivery Time | As per the requirement. Days |

| Sample Available | Yes |

| Sample Policy | Contact us for information regarding our sample policy |

| Certifications | ASNT Level II - Infrared Thermography Testing |

Product Overview

Key Features

Infrared thermography for plant inspection a electrical and mechanical, helps in identifying loose, oxidized, malfunctioning electrical parts emitting hot spots and saves money in lakhs yearly on excessive electricity consumption.

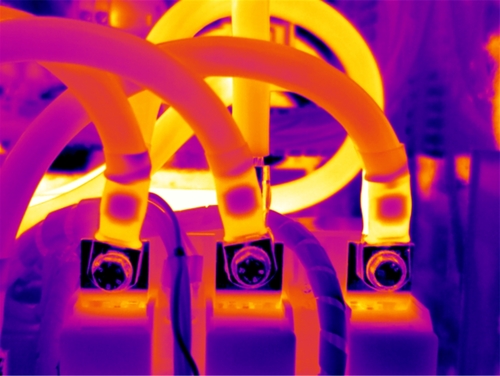

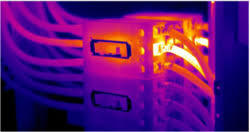

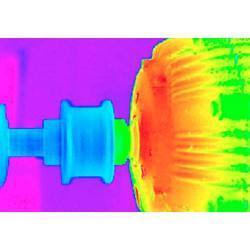

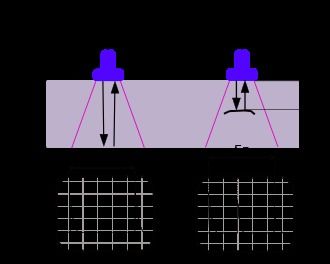

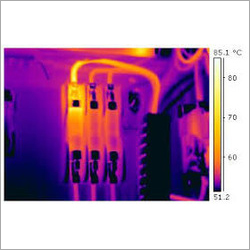

A loose / oxidised wire draws high current which is not visible by human eye, infrared thermography camera detects the heat emitted from it and helps in identifying these hot spots. Also very effective in identifying hot spots in mechanical devices a pumps & motors and the component as shown in the following pictures a thermography inspections for identifying hot spots on electric panels and in the plant on rotational equipments, identifying hot spots saves lots of electricity in a year as power

consumption.

Thermal imaging finds hot spots in electrical preventive maintenance programs .

Routine inspection programmes using Thermal Imagers can often offer the following benefits:- Inspections can be made under full operational conditions and hence there is no loss of production. Equipment life can be extended Plant downtime may be reduced Plant reliability may be increased. Inspection of Mechanical Equipment - The type of mechanical equipment inspected is often rotating machinery. Increased surface temperatures can be the result of internal faults. Excessive heat can be generated by friction in faulty bearings due to wear, misalignment or inadequate lubrication. As with electrical installations it is desirable to perform the inspection with the system in operation wherever practically possible. Interpretation of results should be based on comparison between components operating in similar conditions under similar loads or by trend analysis. Equipment commonly inspected using thermal Imagers is as follows:- Bearings Gears Drive Belts Couplings Shafts Pumps.

Company Details

Business Type

Service Provider, Supplier, Trading Company

Employee Count

10

Establishment

2010

Working Days

Monday To Sunday

Payment Mode

Cheque, Others

Related Products

Explore Related Categories

Seller Details

Vadodara, Gujarat

Proprietor

Mr Sumit J Kainthola

Address

G-11/12, POLO VEIW APARTMENT, OPP. POLO GROUND, RAJ MAHAL ROAD, Vadodara, Gujarat, 390001, India

Report incorrect details