Metals & Alloys

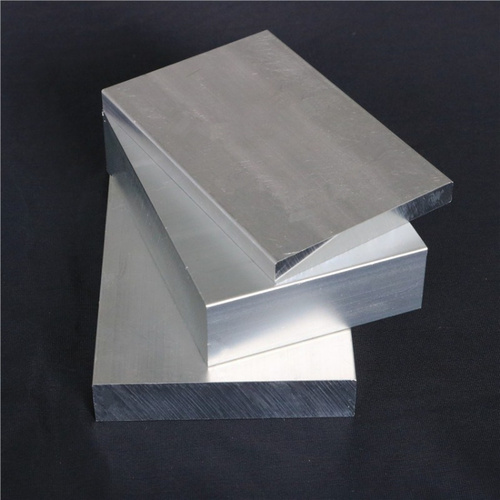

(5549 products)Metal Alloy Aluminium Grade Enaw-5040 / Enaw-Almg1.5Mn

Price: 5000 INR/Number

MOQ1 Number

Product TypeMetal Alloy

MaterialAluminium

AlloyMagnesium

ShapeRod, Wire, Bar, Sheet, Roll, Other

ApplicationOther

Jayant Impex Pvt Ltd

Mumbai

4 Years

Super Premium

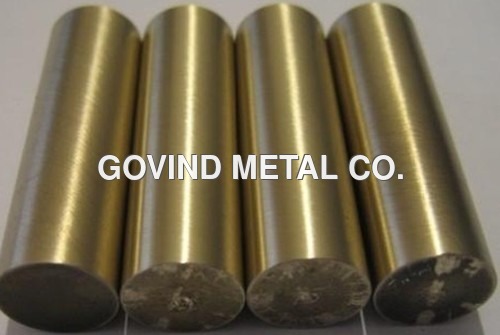

Super PremiumManganese Bronze Application: Machinery

Price: 700.00 INR/Kilograms

MOQ500 Kilograms/Kilograms

Hardness100%

Product TypeMetal

MaterialManganese bronze

ShapeBar, Rod

ApplicationMachinery

ColorGolden

Govind Metal Co.

Ahmedabad

Super Bonanza

Super Bonanza17 Years

Micro Silica Fume Powder

Product DescriptionCoverage Area : High\015\012Type : Powder\015\012Standard : ASTM & BSS\015\012Color : Grey\015\012Grade : Industrial\015\012Packaging Size : 50 Kg\015\012Packaging Type : HDPE Bag\015\012Grade Standard : Industrial Grade\015\012Form : POWDER\015\012Shelf Life : 2 YEAR\015\012Dosage : AS PER MIX DESI

Guru Corporation

Ahmedabad

Super Bonanza

Super Bonanza12 Years

Pure Platinum Tongs - Metal, Standard Size, Silver Color | Polished Surface Finish, Elegant Design

Price: 3200 INR/Gram

MOQ10 Gram/Grams

ColorSilver

Product TypePure platinum tongs

Other MaterialMetal

Surface FinishPolished

SizeStandard

Aditya Agency

Mumbai

4 Years

Silica Fume - Shape: Powder

Price: 15 INR/Kilograms

MOQ50 Kilograms/Kilograms,

Types of RefractoriesOther

ShapePowder

Refsteel Solutions

Ahmedabad

Super Bonanza

Super Bonanza9 Years

Keolin Clay (Grade-KN83)

Price: 16500.00 INR/Ton

MOQ10 Ton/Tons

Payment TermsCash in Advance (CID), Cheque, Cash Advance (CA)

Supply Ability1 Per Day

Delivery Time1 Days

Ryan International

Mumbai

8 Years

Monel Metal Application: Construction

Price Trend: 250.00 - 450.00 INR/Piece

MOQ500 , Piece/Pieces

Product TypeMetal Alloy

ApplicationConstruction

Nascent Pipes & Tubes

Mumbai

11 Years

925-Sterling Silver Grain Alloys - High Purity Silver Composition | Versatile Applications in Jewelry and Crafts

Price: 1500 INR/Unit

MOQ50 , Unit/Units

Product Description925-Sterling Silver Grain Alloys

Indian Platinum Private Limited

Mumbai

16 Years

Construction Grade Micro Silica Fume 25 Kg Bag

Price: 12.0 INR/Kilograms

MOQ10000 Kilogram, Kilogram, Kilogram

Shelf Life12 Months

AppearanceGrey

TasteOdorless

Physical FormPowder

Purity94

ShapeGranules

Adinath Industries

Kishangarh

17 Years

Automotive Lead Alloy - High Purity Rigid Bar | Ideal for Casting Applications, No Moisture

MOQ10 Metric Ton

HardnessRigid

PurityHigh

Product TypeMetal Alloy

MaterialLead

AlloyYes

ShapeBar

Nikita Industries Pvt. Ltd.

Sonipat

9 Years

Hastelloy Sheets - Color: Silver

Price Trend: 10.00 - 100.00 INR/Piece

MOQ10 Piece/Pieces

PurityHigh

HardnessYes

Product TypeMetal

MaterialSS

AlloyYes

ColorSilver

Steel Mart

Mumbai

19 Years

Alcr Sputtering Target Hardness: Rigid

MOQ100 Piece/Pieces

PurityHigh

HardnessRigid

Product TypeMetal

MaterialStainless Steel

AlloyYes

MoistureNil

Tarfilm Hi-tech Co., Ltd.

Suzhou

2 Years

Inconel Long Weld Neck Flanges - Application: Industrial

MOQ100 , Piece/Pieces

ApplicationIndustrial

Product TypeOther, Inconel Long Weld Neck Flanges

MaterialInconel

ShapeRound

SurfacePainted

ColorSilver

Renaissance Fittings & Piping Inc.

Mumbai

8 Years

Silver Alloy 20 Pipes

Price: 2000 INR/Kilograms

MOQ100 Kilograms/Kilograms

ColorSilver

Product TypeAlloy

MaterialAlloy

European Ipb And Heb Beams Application: Construction

Price: 130 INR/Kilograms

MOQ500 Kilograms/Kilograms

Product NameSteel Products

Steel Product TypeOther, European IPB And HEB Beams

GradeS235, S355J2H

SurfaceMill Finish

ApplicationConstruction

Dimension (L*W*H)Length - 6-12 Millimeter (mm)

Eminent Pipe & Profiles Private Limited

Ghaziabad

2 Years

Soft TPU Alloys

Product DescriptionWe offer our client an excellent quality range of Soft TPU Alloys, which are manufactured from high grade quality raw materials. These Soft TPU Alloys can be customized as per our precious customers specifications. These Soft TPU Alloys are widely known for its durability and quality. Our Soft TPU

Phosphor Bronze Round Rods Dimension(L*W*H): 1" - 6" Inch (In)

Price Trend: 700.00 - 900.00 INR/Kilograms

Dimension (L*W*H)1" - 6" Inch (in)

Rakesh Metal & Tubes

Mumbai

12 Years

Silico Manganese Exporters

Price: 50000 INR/Ton

MOQ27 Ton/Tons

Supply Ability50 Per Week

Delivery Time1 Week

Sample AvailableYes

Jajoo Exports

Jaipur

14 Years

Inconel Flange - Application: Steel Making

Price: 1000 INR/Piece

MOQ100 , Piece/Pieces

HardnessYes

ColorSilver

Product TypeMetal

MaterialCarbon steel

ShapeRoll

ApplicationSteel Making

Duplex Steel & Engineering Company

Mumbai

17 Years

441 Silicon Metal Lumps

Price: 300 INR/Kilograms

MOQ1000 Kilograms/Kilograms

FOB Porthajira,porbandar

Packaging Detailsas per product

Unique Metal

Ankleshwar

2 Years

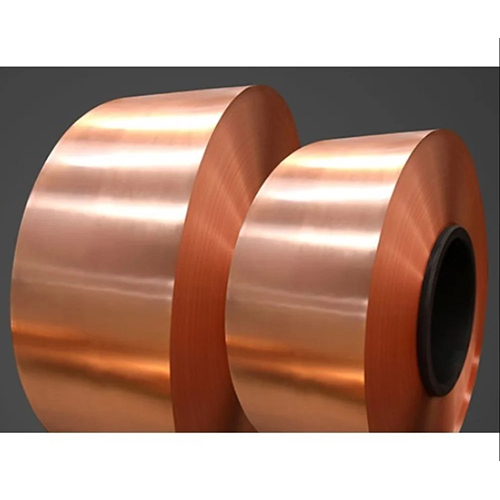

Phosphor Bronze Coil - Purity: 80-99%

Price: 1150 INR/Kilograms

MOQ100 Kilograms/Kilograms

ColorBronze

Purity80-99%

MaterialPhosphor Bronze

AlloyYes

ShapeRoll

MoistureNil

Nilam Traders

Mira Bhayandar

1 Years

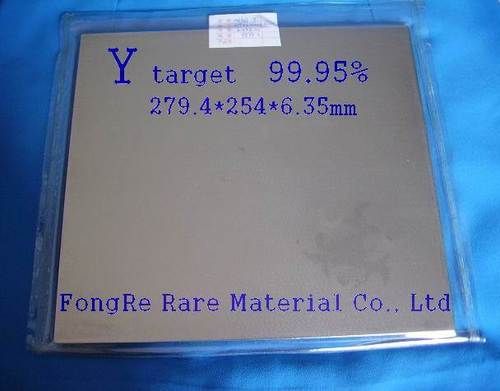

Sputtering Targets - High Purity Metal Alloys | Enhanced Performance for Advanced Nanotechnology Applications

Product DescriptionOur firm have emerged as one of the most prominent names in the industry, engaged in manufacturing and supplying a comprehensive range of Sputtering Targets in Chennai, Tamil Nadu, India. Sputtering is a process whereby particles are ejected from a solid target material due to bombardment of the tar

Thulir Vacuum Technologies

Chennai

9 Years

Grey Insulation Powder

Price Trend: 15.00 - 50.00 INR/Kilograms

MOQ1 Ton/Tons

Purity90 %

MaterialFlux

ShapeGrain

ApplicationOther, For Industrial Use

ColorGrey

Steelcon Industries

Ahmedabad

8 Years

JAPAN Nickel Plate

Price: 1390 INR/Kilograms

MOQ10 Kilograms/Kilograms

Purity99.97%

Product TypeMetal

ShapeSheet

ApplicationCasting

Dimension (L*W*H)4*4*4*4 Inch (in)

Thakur Ji Machine And Tools

Mumbai

2 Years

Inconel 625 Nickel Alloy Coil - Color: Silver

Price: 360 INR/Kilograms

MOQ10 Kilograms/Kilograms

StrengthHigh

Purity80-99%

MaterialInconel

AlloyYes

ApplicationOther, Automobile Industry

ColorSilver

Mahadev Steel India

Mumbai

4 Years

Hastelloy C276 Wire - Color: Silver

Price: 5000 INR/Kilograms

MOQ50 Kilograms/Kilograms

HardnessRigid

MaterialHastelloy

AlloyYes

MoistureNil

ApplicationOther, Industrial

ColorSilver

Gurudev Tubes (india)

Mumbai

1 Years

Nimonic Rods

Product DescriptionOur motto is to achieve excellence thus, we are counted amongst the most prominent processors and suppliers of a broad collection of Nimonic 90 Rod. Our team's extreme endeavor towards the optimum customer gratification has enabled us to attain an towering niche in the market, internationally

Manhar Metal Supply Corporation

Mumbai

18 Years

RETICULATED VITREOUS CARBON FOAM FOR FILTRATION

Price Trend: 100-2000 INR/Kilograms

MOQ5 Kilograms/Kilograms,

Supply Ability1000-10000 Per Day

Delivery Time2-3 Days

Sample AvailableYes

Aritech Chemazone Pvt Ltd.

Kurukshetra

8 Years

Latest From Metals & Alloys

Rare Earth Metals Sputtering Target

By:

Fongre Rare Material Co. Ltd.

Precious Ferrous Metals Alloys

By:

Brrc Metal Products

Metals-Alloys

By:

Dharmi Steel

Hi Chrome ASTM E 1086

By:

Kapasi Metals

Ferro Alloys

By:

Sr Group

Ferro Silicon

By:

Crystal Sleeves Mfg Pvt Ltd

SPECIAL Metals & Alloys

By:

Special Metals

Ready To Ship Metals & Alloys

Metal and Alloys: Types, Advantages and Applications

There is a lot of back and forth concerning whether or not pure metal is better than metal alloys. Metal alloys offer a number of advantages over pure metals. Find out why alloys are preferable to pure metals and how you might benefit from them.

1. Metal alloys are stronger than pure metals

Stronger buildings can be constructed or made utilizing alloys, which is one of its many benefits. Alloys are composites of multiple metals, combining the best qualities of each while eliminating their undesirable ones.

By doing so, a compound is formed that is superior in strength to the metal from which it was derived. Most metals are too soft to be used in their purest form, therefore they are alloyed with one another to make a stronger metal.

As opposed to pure metal, which consists of identical atoms, alloys of metals contain a variety of different elements.

2. Metal alloys are more versatile than pure metals

Alloys of metals can be used in more applications than their pure metal counterparts. Metal alloys are mixtures of multiple metals and non-metals, while pure metals are what they are and don't lend themselves to much manipulation or alteration.

This opens the door to further customization and the enhancement of preferable qualities for specific uses.

3. Metal alloys are more resistant to corrosion than pure metals

The corrosion resistance of metal alloys is often substantially higher than that of pure metals.

The aluminum bronze alloys we sell are extremely sturdy and resistant to corrosion. That's because metal alloys are composites made up of many metals and non-metal components that work together to produce a superior alloy.

Alloys can be engineered to withstand corrosion, whereas pure metals are chemically reactive and readily corrode. Damage from corrosion to metals can quickly add up.

Types of Metal Alloys

1. Cast Iron Alloy

Cast iron is a molten form of iron-carbon alloys with a carbon content of more than 2%. When the metal is melted, it is poured into a mold. There is a distinction between the making of wrought iron and cast iron. You can't hammer or otherwise shape cast iron.

Gray iron gets its moniker because its graphite molecules are flake-shaped. The broken graphite flakes give the fractured metal its characteristic gray appearance.

2. Brass Alloys

The copper and zinc alloy called as brass has made a big historical effect because to its durability and malleability. Calamine brass, the earliest form of brass, was likely made in the Neolithic period through the reduction of copper and zinc ores.

In many instances, ancient manuscripts misunderstand brass, an alloy of copper and tin, and refer to it as bronze.

The ductility of brass depends on its zinc content; brasses with greater than 45% zinc are unworkable in either high heat or extreme cold.

3. Molybdenum Alloys

Powder metallurgy techniques are commonly used in the production of molybdenum. Molybdenum metal is produced by hydrostatically compacting Mo powder and then sintered at about 2100°C (3812°F). Between 1598 and 2300 degrees Fahrenheit (870 to 1260 Celsius), hot work is performed.

4. Niobium Alloys

Niobium, also known as columbium, is a shiny, ductile metal commonly used in alloys. It is used commonly in structural applications, jet engines, and gas pipelines due to its ability to improve steel's properties.

Due to its high performance and resistance to corrosion at high temperatures, niobium metal is used in sputtering targets (sites/places intended to be coated with another material) and processing equipment for chemicals.

5. Titanium Alloys

Many different metals and compounds can be found in titanium alloys, however titanium is usually the dominant metal. Titanium alloys are produced by mixing titanium with other metals and chemical components in a certain ratio.

6. Bronze Alloys

Current bronze typically consists of 88% copper and 12% tin. The history and continued relevance of bronze are two of its greatest attractions.

Bronze is stronger than copper because it is an alloy of copper and tin or another metal.

In addition, bronze can be melted and cast more easily than some other materials. It is stronger and more resistant to corrosion than regular iron.

7. Nickel Alloys

Pure nickel has excellent corrosion resistance, making it useful in the chemical industry. Transducers also make use of it due to its capacity to prevent electromagnetic interference.

Nickel-iron alloys are widely used as soft magnetic materials and glass-to-metal seals due to their low thermal expansion rates.

Invar (UNS K93600), which is composed of 36% nickel and the balance iron, is unusual because it exhibits almost no thermal expansion at ambient temperature.

8. Aluminum Alloys

Aluminum alloys are known for their durability, dependability, and versatility. Like steel, they are one of the most widely used metals & alloys and are in high demand for a wide variety of industrial, architectural, and vehicular uses.

The alloy components are mixed when aluminum is molten (liquid), and a homogenous solid solution is produced upon cooling.

10. Stainless Steel Alloys

It is possible to further enhance stainless steel's mechanical and corrosion resistance by adding other elements such as nickel, titanium, molybdenum, niobium, molybdenum, etc. Because of the chromium in the substance, chromium oxide forms on its surface when exposed to air.

Metal & Alloys Examples

1. Bronze

Coins, blades, and turbines are all made from this metal alloy because of its strength and durability. Commercial bronze, a copper alloy, outperforms copper in terms of strength, outweighs steel in weight, and has a relatively low melting point.

2. Steel

Steel (iron/carbon) combined with chromium, aluminum, or other components produce a metal with exceptional resistance to corrosion. Stainless steel's rust-proof properties come from the chromium it's alloyed with.

3. Brass

Nuts, bolts, pipe fitting, door hardware, appliance trim, clock components, marine engines, seawater pipes, gas valves, and much more all require copper-zinc alloys.

4. Alnico

The alnico is the third strongest magnet material after neodymium and samarium-cobalt because of its ferromagnetic properties.

Commonly Used Elements for Alloying

1. Nickel

Because of its role as an austenite promoter, nickel is a key ingredient in the production of austenitic stainless steels. Austenitic stainless steel is produced when the chromium content is at least 18% and the nickel content is at least 8%.

2. Manganese

Iron and carbon are the two main components of steel, however, manganese is also commonly added to help with heat treatment. In order to increase the hardness and strength of steels, they must be heated and then quickly quenched. Instability increases when the rate at which this occurs increases.

3. Vanadium

The grain size of the steel can be kept tiny with the help of vanadium. The addition of vanadium to steel prevents the production of grains, which keeps the grain size manageable.

4. Molybdenum

Like chromium, molybdenum can improve steel's resistance to corrosion. Steel's hardenability, toughness, and tensile strength can all be improved with the addition of molybdenum.

By decreasing the necessary quench rate during heat treatment, hardenability is increased, allowing for the creation of a steel that is both strong and hard.

5. Chromium

Stainless steel is created when more than 11% chromium is added to carbon steel. Because iron is shielded from oxidation in many conditions, steel's corrosion resistance is much enhanced with this carbon level. Because chromium oxidizes before iron does, it forms a barrier that prevents the iron from rusting.

FAQs: Metal and Alloys

Q. Metal Alloys Applications?

Ans. Here are the applications:

1. Belts, staples, cables, Screening, welds, catheters, and suture wires are just some of the many applications for wire and ribbon made from stainless steel.

2. Jewelry is commonly made out of gold and silver alloys. As a more affordable alternative to platinum, white gold (an alloy of gold, silver, palladium, and nickel) is frequently used.

3. In a wide range of sectors, several alloys are used for welding.

4. Because of their resistance to corrosion, alloys find application in wet environments.

5. High-temperature alloys are essential in the petrochemical and aerospace sectors. Wire welding under extreme conditions and high temperatures has also been successfully implemented using these alloys.

Q. What are Metal Alloys?

Ans. At least one of the constituent chemicals in an alloy must be a metal. In contrast to compounds with metallic bases, the properties of a metal, such as its opacity, conductivity, luster and ductility, are maintained in an alloy.

Q. What is the difference between metal and alloy?

Ans. Pure metals have only one kind of atom in them. One such pure metal is chromium, which can be verified by looking it up on the periodic chart. In contrast, atoms of different elements are melted together to form an alloy.

Q. What are the types of alloys?

Ans. Here are the basic types:

1. Aluminium Alloys

2. Stainless Steel Alloys

3. Nickel Alloys

4. Gold Alloys

Q. What are metals and alloys used for?

Ans. They find widespread application in the aerospace, manufacturing, healthcare, and defense sectors. Aluminum, nickel, copper, stainless steel, and titanium are only few of the alloys used in industrial and automobile production.

Related Topic:

Metals & Alloys Manufacturers, Suppliers & Exporters in India - Top 10

Manufacturers & Suppliers of Metals & Alloys

Company Name | Member Since |

|---|---|

Steel Mart Mumbai, India | 19 Years |

Manhar Metal Supply Corporation Mumbai, India | 18 Years |

Govind Metal Co. Ahmedabad, India | 17 Years |

Adinath Industries Kishangarh, India | 17 Years |

Duplex Steel & Engineering Company Mumbai, India | 17 Years |

Indian Platinum Private Limited Mumbai, India | 16 Years |

Jajoo Exports Jaipur, India | 14 Years |

Guru Corporation Ahmedabad, India | 12 Years |

Rakesh Metal & Tubes Mumbai, India | 12 Years |

Nascent Pipes & Tubes Mumbai, India | 11 Years |

Popular Products